Preparation method for subject-object self-repairing transparent film

A transparent film, self-healing technology, applied in coatings and other directions, can solve the problems of unreported self-healing coatings, and achieve the effects of simple operation, wide application range and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing a host-guest self-healing transparent film, the preparation of the self-healing film includes the following steps:

[0028] Step 1. Mix 45-90 mg of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride with 27-50 mg of N-N-hydroxysuccinimide to obtain a mixed solution I, and then mix Add 300-350 mg of β-cyclodextrin and 160-200 mg of branched polyetherimide into mixed solution I, and react at room temperature for 12-24 hours to obtain branched polyethyleneimine modified with β-cyclodextrin; mix 100- 185mg 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride was mixed with 30-45mg N-N-hydroxysuccinimide to obtain mixed solution II, and then 80-120mg adamantane was mixed with 160 ~200 mg of polyacrylic acid is added to the mixed solution II, and reacted at room temperature for 12 to 24 hours to obtain polyacrylic acid modified with adamantane.

[0029] Step 2. Immerse the glass sheet, silicon sheet or metal alloy sheet in the acetone sol...

Embodiment 1

[0032] 1) Mix 45mg of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride with 27mg of N-N-hydroxysuccinimide to obtain a mixed solution I, then mix 300mg of β-cyclodextrin with 160mg of Branched polyetherimide was added to mixed solution I, and reacted for 12 hours at room temperature to obtain branched polyethyleneimine modified with β-cyclodextrin; 100mg of 1-ethyl-(3-dimethylaminopropyl base) carbodiimide hydrochloride and 30mg N-N-hydroxysuccinimide were mixed to obtain a mixed solution II, and then 80 mg adamantane and 160 mg polyacrylic acid were added to the mixed solution II and reacted for 12 hours at room temperature to obtain the modified Polyacrylic acid modified with adamantane.

[0033] 2) Dip the glass sheet in acetone solution for 30 minutes, and then immerse it in ethanol solution for 30 minutes; finally immerse it in H 2 SO 4 -H 2 O 2 Soak in the mixed solution for 4 hours, blow dry with nitrogen to obtain a cleaned glass sheet.

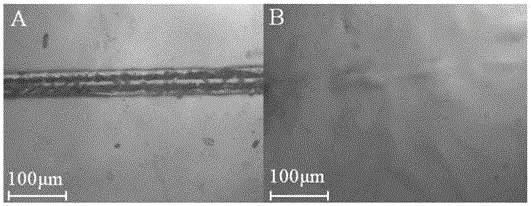

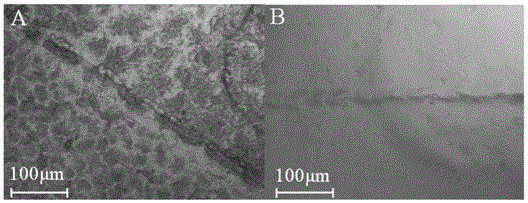

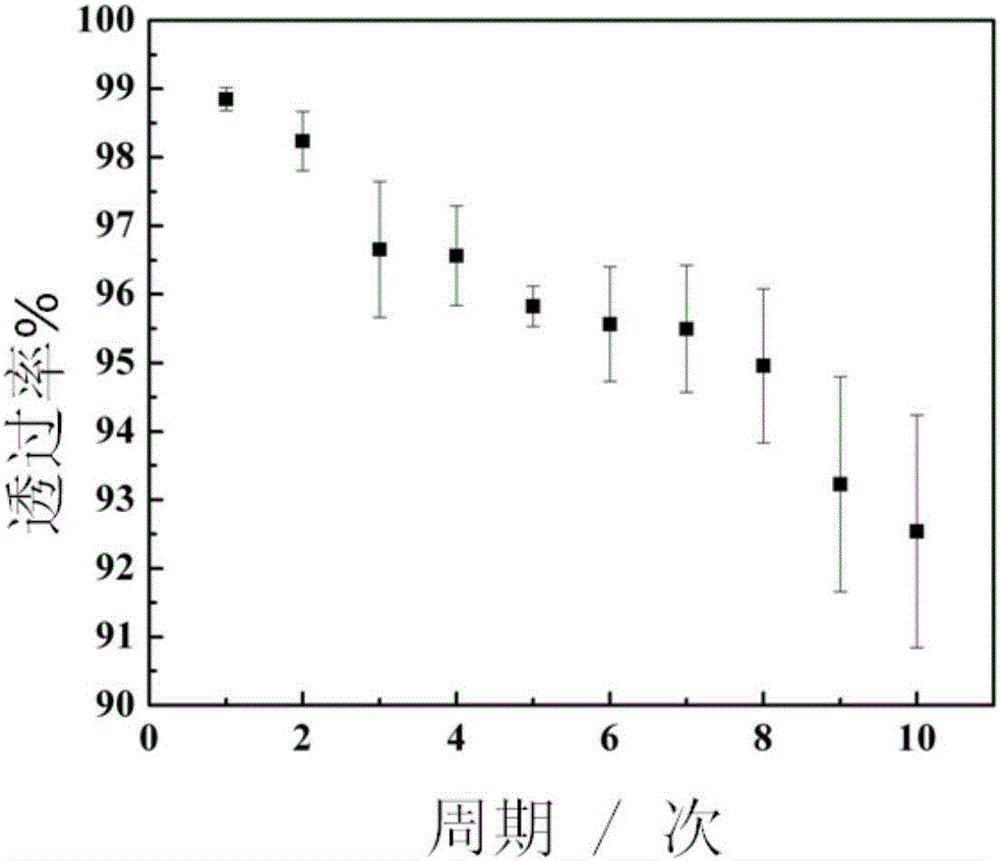

[0034] 3) Soak ...

Embodiment 2

[0039] 1) Mix 55mg of 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride with 32mg of N-N-hydroxysuccinimide to obtain a mixed solution I, then mix 320mg of β-cyclodextrin with 175mg of Branched polyetherimide was added to the mixed solution I, and reacted for 16 hours at room temperature to obtain branched polyethyleneimine modified with β-cyclodextrin; 113mg of 1-ethyl-(3-dimethylaminopropyl Base) carbodiimide hydrochloride and 32mg N-N-hydroxysuccinimide were mixed to obtain a mixed solution II, and then 90 mg adamantane and 175 mg polyacrylic acid were added to the mixed solution II, and reacted for 16 hours at room temperature to obtain the modified Polyacrylic acid modified with adamantane.

[0040] 2) Dip the silicon wafer in acetone solution for 40 minutes, then immerse in ethanol solution for 40 minutes; finally immerse in H 2 SO 4 -H 2 O 2 Soak in the mixed solution for 6h, N 2 Blow dry to obtain a cleaned silicon wafer.

[0041] 3) Soak the cleaned sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com