Low-water-absorptivity stone-like coating emulsion and preparation method thereof

A low water absorption, real stone paint technology, applied in the field of architectural coatings, can solve the problems of local deep color, water absorption and softening, blooming, etc., and achieve the effect of small molecular weight, small CMC value, and effective penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

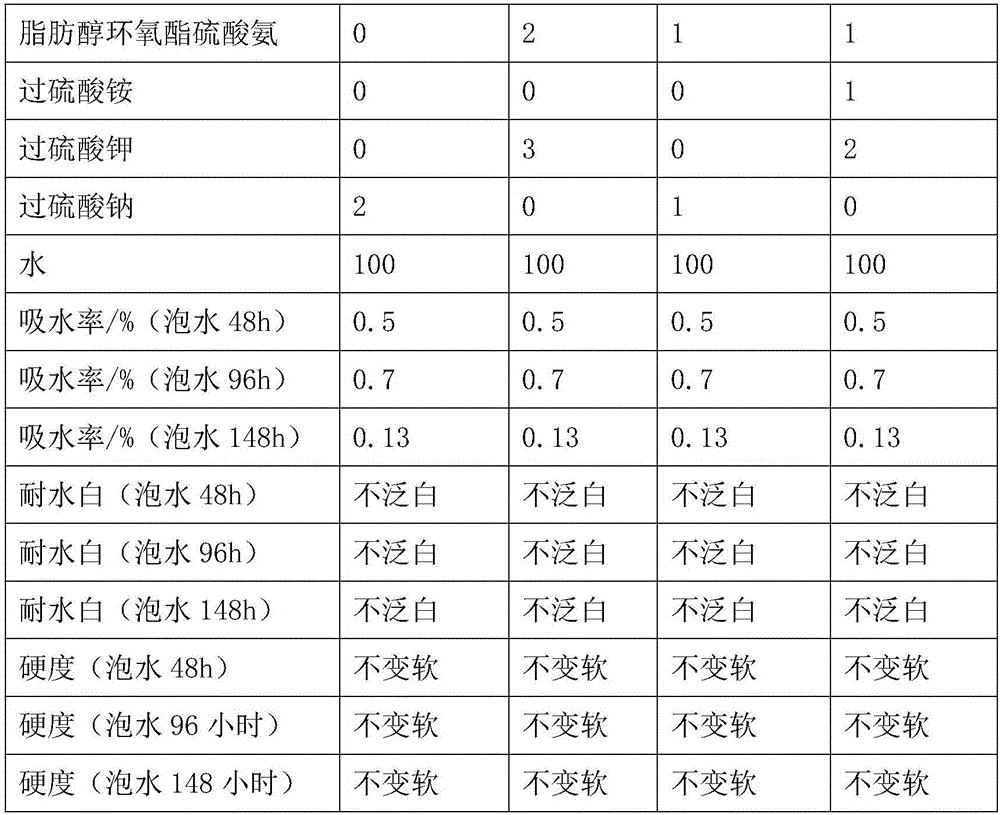

Embodiment 1

[0046] Prepare a low water-absorbing real stone paint emulsion, comprising the following steps in order:

[0047] (1) Weigh the following raw materials in parts by weight for later use: 35 parts of methyl methacrylate, 10 parts of styrene, 30 parts of isooctyl acrylate, 3 parts of methylene succinic acid, 2 parts of glycidyl methacrylate , 3 parts of sodium dodecylbenzenesulfonate, 2 parts of sodium persulfate, 100 parts of water;

[0048] (2) At room temperature, fully stir styrene, isooctyl acrylate, glycidyl methacrylate, and 70% methyl methacrylate in an emulsification tank to obtain a mixture A for later use;

[0049] (3) Sodium dodecylbenzenesulfonate, methylene succinic acid, and 97% water were added to the reaction kettle, and fully stirred evenly to obtain mixture B;

[0050](4) The mixture B was heated up to 78°C, then 80% sodium persulfate was added and stirred for 10 minutes, then the mixture A was added dropwise to the reaction kettle at a constant speed, and the...

Embodiment 2

[0056] Prepare a low water-absorbing real stone paint emulsion, comprising the following steps in order:

[0057] (1) Weigh the following raw materials in parts by weight for later use: 40 parts of methyl methacrylate, 5 parts of styrene, 30 parts of isooctyl acrylate, 2 parts of methylene succinic acid, and 3 parts of allyl methacrylate , 2 parts of fatty alcohol epoxy ester ammonium sulfate, 3 parts of potassium persulfate, 100 parts of water;

[0058] (2) At room temperature, fully stir styrene, isooctyl acrylate, allyl methacrylate, and 80% methyl methacrylate in an emulsification tank to obtain mixture A, and set aside;

[0059] (3) Add fatty alcohol epoxy ester ammonium sulfate, methylene succinic acid, and 96% water into the reaction kettle, and stir well to obtain mixture B;

[0060] (4) The mixture B was heated to 83° C., then 85% potassium persulfate was added and stirred for 10 minutes, and then the mixture A was added dropwise to the reaction kettle at a constant ...

Embodiment 3

[0066] Prepare a low water-absorbing real stone paint emulsion, comprising the following steps in order:

[0067] (1) Weigh the following raw materials in parts by weight for later use: 20 parts of methyl methacrylate, 20 parts of styrene, 20 parts of isooctyl acrylate, 5 parts of methylene succinic acid, 5 parts of cross-linking monomer, emulsified 2 parts of agent, 1 part of sodium persulfate, 100 parts of water;

[0068] (2) At room temperature, fully stir styrene, isooctyl acrylate, cross-linking monomer, and 75% methyl methacrylate in an emulsification tank to obtain mixture A, and set aside;

[0069] (3) Add emulsifier, methylene succinic acid, and 95% water into the reaction kettle, and fully stir evenly to obtain mixture B;

[0070] (4) The mixture B was heated up to 80°C, then 90% sodium persulfate was added and stirred for 10 minutes, then the mixture A was added dropwise to the reaction kettle at a constant speed, and the dropping time was 3.5 hours, and the stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com