Polyurethane foam material, preparation method and uses thereof

A polyurethane foam and urethane technology, which is applied in the field of polyurethane foam materials and their preparation, can solve the problems of inability to take into account the air permeability, permanent compression deformation and density of polyurethane foam materials, increase in permanent compression deformation of materials, and low density air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

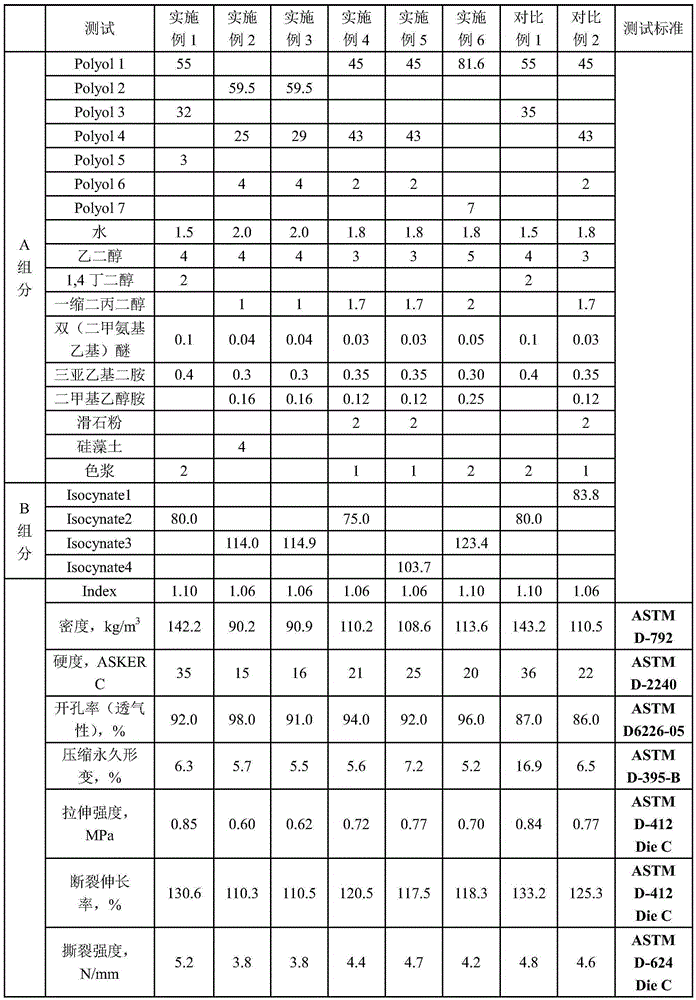

Examples

preparation example Construction

[0082] Preparation of Isocynate1: Add 550g of diphenylmethane diisocyanate into a three-necked flask equipped with a stirrer, a thermometer, and a nitrogen tube, heat it to 60-70°C, and then add Polyol8, Polyol9, and Polyol10. The added masses are 15g, 20g and 215g. Raise the temperature to 80°C, stir at a speed of 50 rpm for 2 hours, adjust the temperature of the stirred product to 40°C, add 200 g of carbodiimide-modified isocyanate, and stir for 0.5 hours to obtain Isocynate1, the NCO of Isocynate1 The content is controlled at 19.9-20.9wt%, and the viscosity is 650mPa·s;

[0083] Preparation of Isocynate2: Add 500g of diphenylmethane diisocyanate into a three-necked flask equipped with a stirrer, a thermometer, and a nitrogen tube, heat it to 60-70°C, and then add Polyol8, Polyol10, and Polyol12. The added masses are 20g, 105g and 105g. Raise the temperature to 80°C, stir at a speed of 100 rpm for 2 hours, adjust the temperature of the stirred product to 50°C, add 270g of ...

Embodiment 1

[0088] At room temperature, put the raw materials of component A into the reaction kettle one by one, and stir for 10 minutes with a high-speed shear mixer at a stirring speed of 1500 rpm. The temperature of the components and Isocynate2 is up to 22°C, put the A component and Isocynate2 into a box foam machine and stir for 22 seconds, pour into a mold at 35°C, and open the mold after aging for 20 minutes to obtain the polyurethane foam of the present invention ; After placing the polyurethane foam at room temperature for 30 hours, test the mechanical properties.

Embodiment 2

[0090] At room temperature, put the raw materials of component A into the reaction kettle one by one, stir for 15 minutes with a high-speed shear mixer, the stirring speed is 2500 rpm, and the material is discharged as component A with a viscosity of 2800mPa·s; The temperature of the component and Isocynate3 is at 21°C and 18°C, put the A component and Isocynate3 into a box foam machine and stir for 20 seconds, pour it into a mold at 30°C, and open the mold after aging for 25 minutes to obtain the present invention. The polyurethane foam; after placing the polyurethane foam at room temperature for 30 hours, the mechanical properties were tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com