Method for preparing sec-butyl alcohol

A technology of sec-butanol and sec-butyl acetate, which is applied in the field of preparation of sec-butanol, can solve the problems of low conversion rate, low purity, inability to separate sec-butanol and sec-butyl acetate, etc., and improve the conversion rate , the effect of meeting the material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

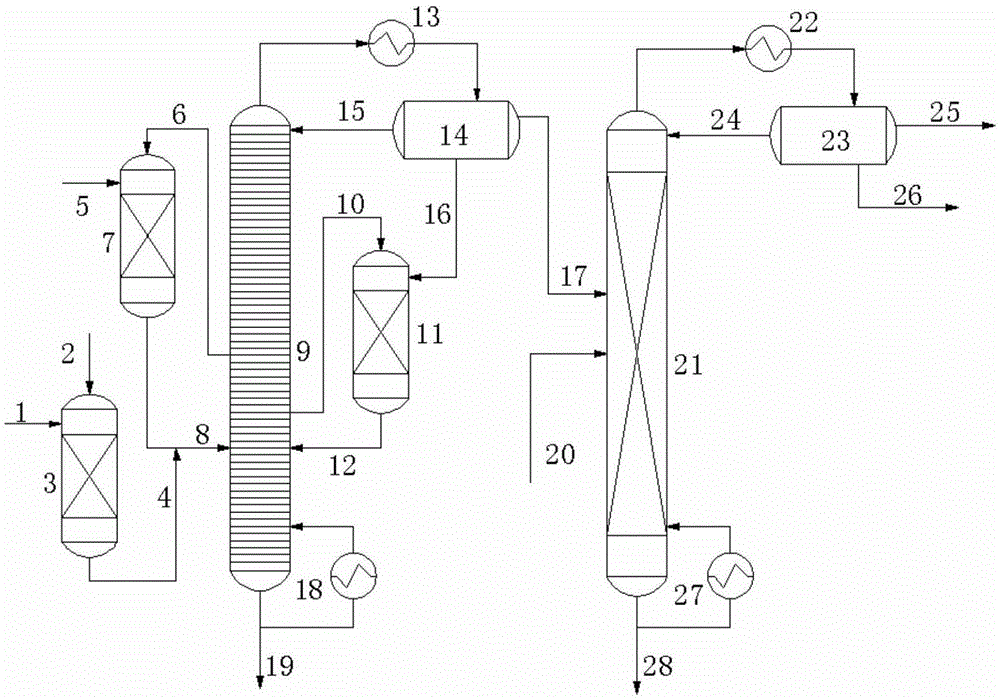

[0064] The sec-butyl acetate raw material 2 is sent into the hydrolysis reactor 3 with the speed of 30t / h, wherein, the sec-butyl acetate is a commercially available product purchased, and the industrial purity is 99.54%, and water 1 is added simultaneously, wherein, water and acetic acid The molar ratio of sec-butyl ester is 1.05:1, the temperature of the reactor is 60°C, and the reaction pressure is 1.0MPa. The mixture 4 of sec-butanol, water and sec-butyl acetate obtained through hydrolysis reaction is at a speed of 34.9t / h Send into the deacidification tower 9, the deacidification tower is a plate tower, the number of theoretical plates is 60, the feed port of the deacidification tower is set at the 35th tray, and the side line of the deacidification tower is provided with 2 side reactors 7 and 11 are respectively located at the 20th and 30th theoretical plates of the deacidification tower. The reaction temperature of the control side reactor is 80°C, the reaction pressure ...

Embodiment 2

[0067]The sec-butyl acetate raw material 2 is sent into the hydrolysis reactor 3 with the speed of 64t / h, and the sec-butyl acetate raw material is obtained from Chinese patent application CN103980115A step (1) containing sec-butyl acetate, C8 olefins and unreacted acetic acid The bottom product, wherein, the mass content of sec-butyl acetate is 46.87%, the mass content of acetic acid is 43.45%, the mass content of C8 olefins is 8.63%, and the mass content of sec-butanol is 1.05%. Water 1 is added to the hydrolysis reactor at the same time, wherein the molar ratio of water to sec-butyl acetate is 0.5:1, the temperature of the reactor is 70°C, and the reaction pressure is 0.6MPa. The sec-butanol and water obtained through the hydrolysis reaction , the mixture 4 of acetic acid, C8 olefin and sec-butyl acetate is sent into the deacidification tower with the speed of 66.3t / h, and the deacidification tower is a plate tower, and the number of theoretical plates is 40, and the feed in...

Embodiment 3

[0070] The sec-butyl acetate raw material 2 is sent into the hydrolysis reactor 3 with the speed of 30t / h, wherein, the sec-butyl acetate is a commercially available product purchased, and the industrial purity is 99.67%, and water 1 is added simultaneously, wherein, water and acetic acid The molar ratio of sec-butyl ester is 1.2:1, the temperature of the reactor is 80°C, and the reaction pressure is 0.7MPa. The mixture 4 of sec-butanol, water and sec-butyl acetate obtained through hydrolysis reaction is at a speed of 35.6t / h Send into the deacidification tower 9, the deacidification tower is a plate tower, the number of theoretical plates is 50, the feed port of the deacidification tower is arranged at the 30th tray, and the side line of the deacidification tower is provided with 3 side reactors , respectively located at the 20th, 25th, and 29th theoretical plates of the deacidification tower, the reaction temperature of the control side reactor is 100°C, the reaction pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com