A Method for Improving Radiation Aging Resistance of Explosive Parts

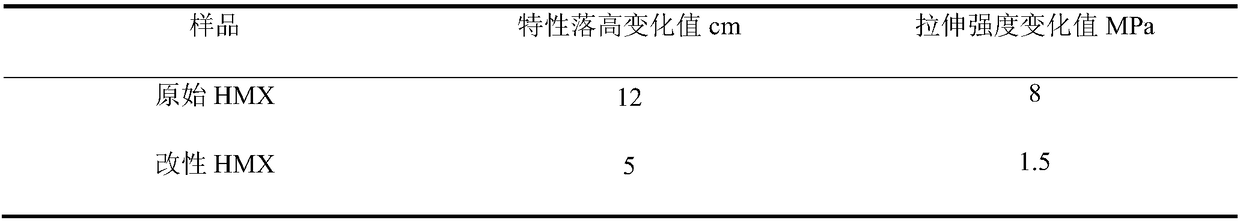

A technology of anti-radiation and explosives, which is applied in the fields of improving anti-radiation aging of explosives and improving the performance of explosives. It can solve problems such as unpredictable output performance and gradual changes in performance, and achieve the effect of improving the performance of anti-radiation aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for improving the radiation aging resistance of explosives, comprising:

[0043] Step 1: Prepare 200 mL of Tris solution with a concentration of 20 mmol / L;

[0044] Step 2: Dissolve dopamine hydrochloride at a concentration of 2 g / L in the Tris solution. After complete dissolution, the pH value of the solution is 8.5. Use a stirrer to stir and mix the dispersion at a speed of 500 r / min for 12 hours;

[0045] Step 3: Suction filter and wash the stirred dispersion liquid, wash with distilled water for 3 times, and separate out the polymer;

[0046] Step 4: placing the cleaned material in an oven at 50°C for 5 hours to obtain a dopa polymer material;

[0047] Step 5: Add the dopa polymer directly into the HMX explosive slurry at a content of 1% by mass fraction, and obtain a radiation-resistant HMX-based explosive after the explosive is cured.

Embodiment 2

[0049] A method for improving the radiation aging resistance of explosives, comprising:

[0050] Step 1: Prepare 200 mL of Tris solution with a concentration of 20 mmol / L;

[0051] Step 2: Dissolve dopamine hydrochloride at a concentration of 4 g / L in the Tris solution. After complete dissolution, the pH of the solution is 8.5. Use a stirrer to stir and mix the dispersion at a speed of 500 r / min for 12 hours;

[0052] Step 3: Suction filter and wash the stirred dispersion liquid, wash with distilled water for 3 times, and separate out the polymer;

[0053] Step 4: placing the cleaned material in an oven at 50°C for 5 hours to obtain a dopa polymer material;

[0054] Step 5: The dopa polymer is directly added to the TATB explosive slurry at a content of 5% by mass fraction, and after the explosive is cured, a radiation-resistant aging-resistant TATB explosive is obtained.

Embodiment 3

[0056] A method for improving the radiation aging resistance of explosives, comprising:

[0057] Step 1: Prepare 200 mL of Tris solution with a concentration of 20 mmol / L;

[0058] Step 2: Dissolve dopamine hydrochloride with a concentration of 2g / L in the Tris solution. After the solution is completely dissolved, the pH value of the solution is 8.5, then add 20g of HMX to the solution, and use a stirrer to stir and mix the dispersion at a speed of 500r / min. The stirring time for 12h;

[0059] Step 3: Suction filter and clean the stirred dispersion liquid, wash with distilled water for 3 times, and separate the in-situ polymerized HMX modified material;

[0060] Step 4: Place the cleaned material in an oven at 50°C for 5 hours to obtain an in-situ polymerized HMX modified material;

[0061] Step 5: Based on the in-situ polymerized HMX modified material, the modified HMX-based explosive is obtained by casting to obtain an anti-radiation aging explosive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com