A kind of selenium-enriched and cadmium-reduced foliar silicon fertilizer and its preparation method and application

A technology for reducing cadmium and foliage, applied in application, silicon oxide, silicon dioxide and other directions, can solve the problems of inorganic selenite poisoning, low conversion rate of selenium, burning of plants, etc., to inhibit the absorption and accumulation of heavy metals by crops, Improve heavy metal resistance, improve the effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: Preparation of nano-silica sol

[0055] (1) Choose SiO 2 / Na 2 1. Sodium silicate with a molar ratio of 3.2 is prepared into 500ml of sodium silicate solution with a mass concentration of 10%, and magnetically stirred for 1h at room temperature; the silicate solution is directly filtered through a multi-stage resin exchange column to remove the silicate in the silicate Metal ions, while adding 150ml of hydrochloric acid solution with a mass concentration of 5% for acidification, and controlling the column mouth to collect the filtrate to obtain an active silicic acid aqueous solution with a pH value between 1 and 4.

[0056] (2) Prepare a 0.5M sodium hydroxide solution, and add it dropwise to the active silicic acid aqueous solution obtained in step (1) under the condition of strong stirring at 1000rpm, until the pH reaches 10, stop the dripping, so that the silicic acid gradually dissolves in the alkali Polymerized into silica particles under neutral co...

Embodiment 2

[0061] Embodiment 2: prepare chitosan selenium solution

[0062] (1) Preparation of precursor solution

[0063] Take 0.5g of sodium selenite dissolved in 250ml of distilled water, add 2.5g of ethanol as a protective agent, stir for 20min, then insert the ultrasonic in-line processor into the evenly stirred solution, the ultrasonic intensity is 800KHZ, start the ultrasonic wave to prepare dropwise reduction agent solution;

[0064] (2) Addition of reducing agent

[0065] After weighing 0.2g sodium borohydride and adding 200ml of water to dissolve, add dropwise to the precursor solution prepared in step (1) under ultrasonic conditions to prepare seed crystals, then add dropwise 50ml of ascorbic acid, hydroxylamine hydrochloride mixed solution (ascorbic acid, hydrochloric acid in the mixed solution The concentration of hydroxylamine is 0.04mol / L) as the reducing agent in the production process. After reacting for 2h, the temperature rises to 55°C and stirs at a constant tempera...

Embodiment 3

[0068] Embodiment 3: Preparation of selenium doped silica sol

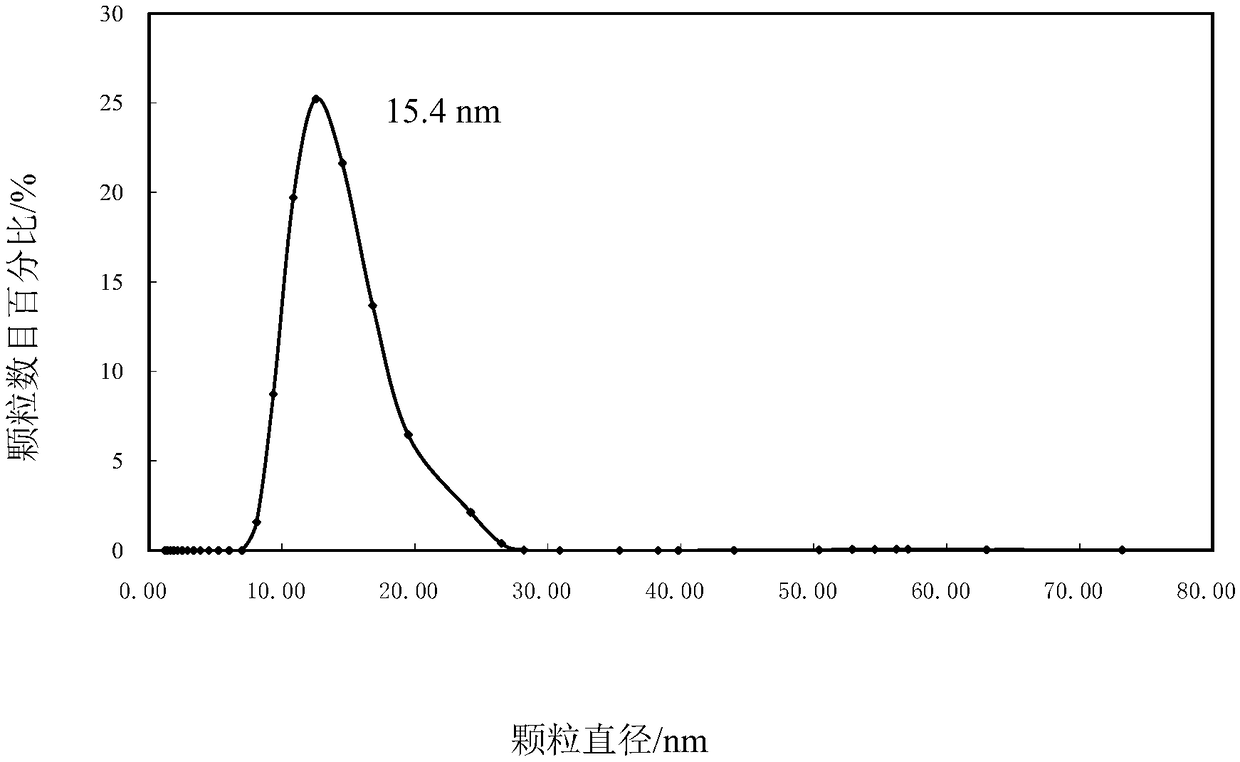

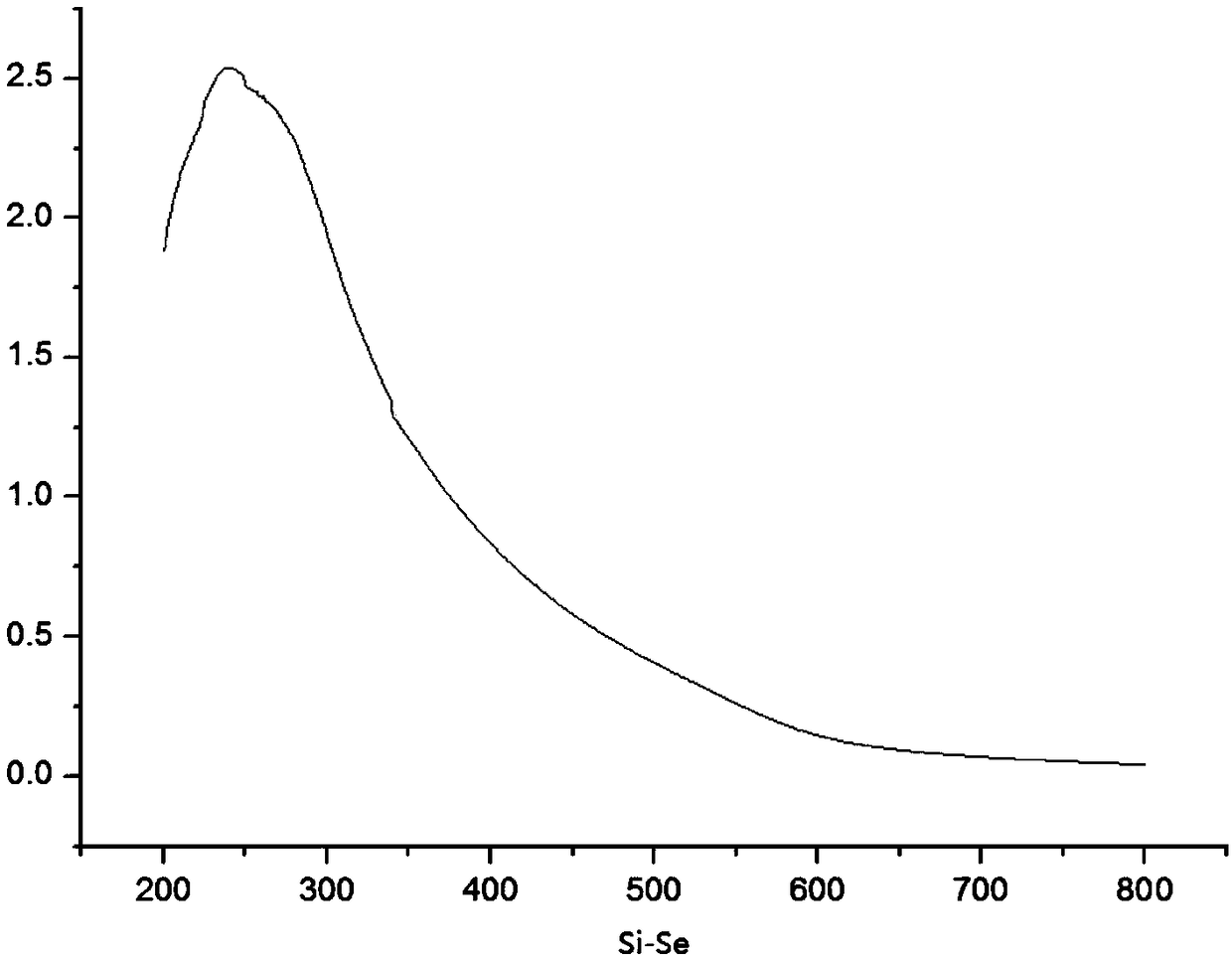

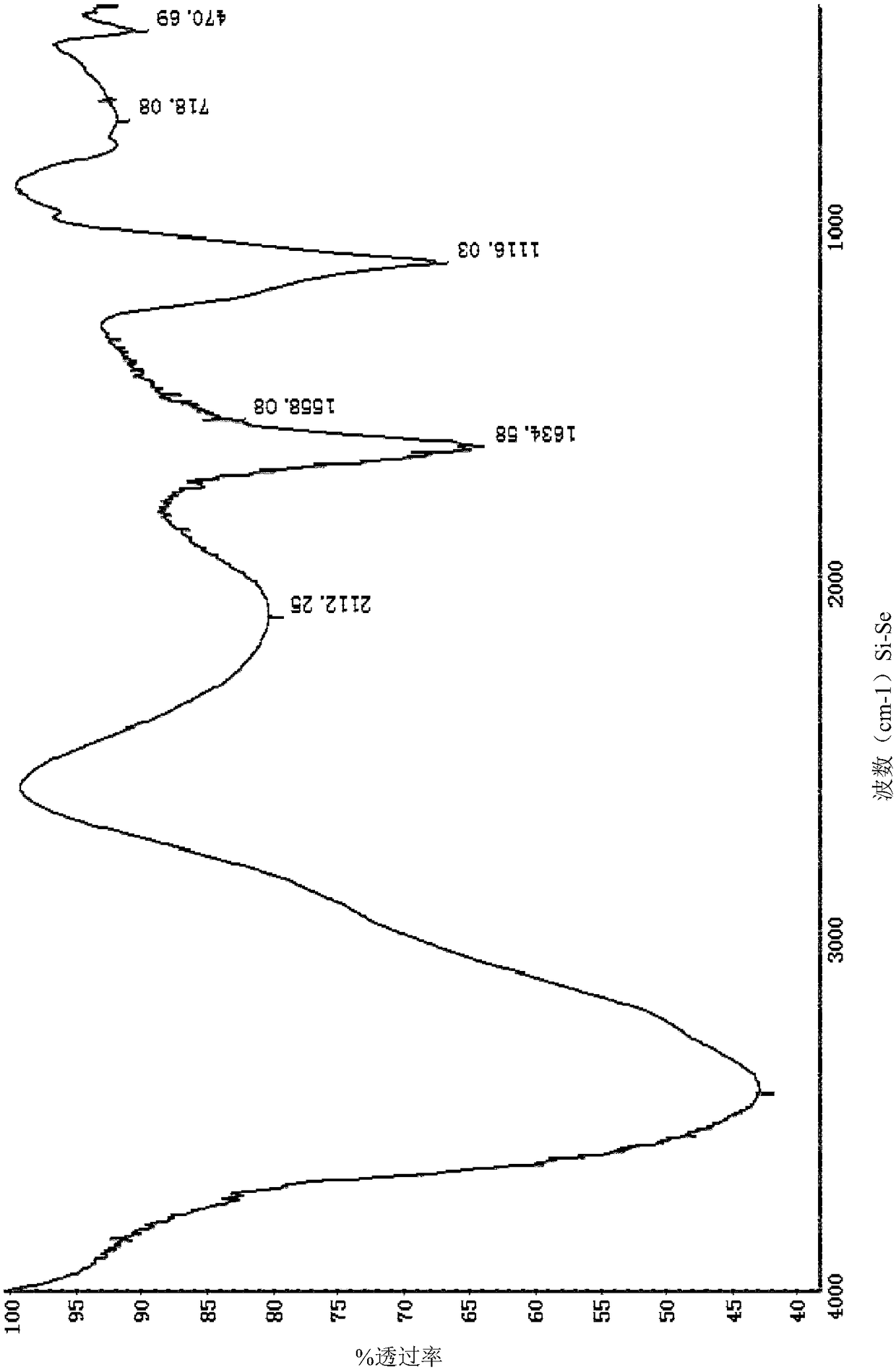

[0069] With the nano-silica sol prepared in Example 1 and the chitosan selenium solution prepared in Example 2, the selenium / silicon mol ratio is 1:100, 2:100, 3:100, 4:100, 5:100 respectively The proportions of each other are dissolved, mixed, adsorbed, and the pH is adjusted to 7 with lye to form organic selenium-doped silica sols with different doping concentrations. The selenium content of organic selenium-doped silica sols prepared with selenium / silicon molar ratios of 1:100, 2:100, 3:100, 4:100, and 5:100 were 0.5g / L and 1.0g / L respectively , 1.5g / L, 2.0g / L, 2.5g / L. Among them, the particle size distribution of selenium-doped silica sol with a selenium content of 1g / L is as follows: figure 1 As shown, the particle size of the selenium-doped composite nano-silica sol is small, generally less than 20nm, and the particle size is single. The sol infrared spectrum and ultraviolet-visible spectrum synthesized b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com