Preparation method of straw organic liquid specially used for crops

A technology for crop straws and crops is applied in the field of preparation of crop straw organic liquid, which can solve the problems of short production cycle, low production cost, short duration and the like, and achieve the effects of pollution-free production environment, reliable use and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

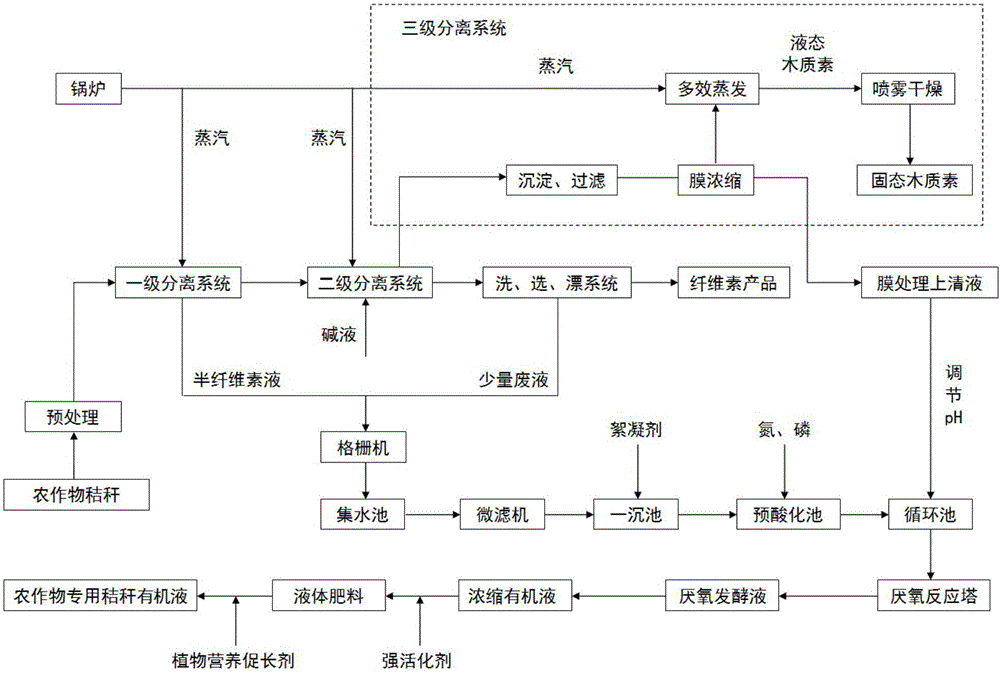

Method used

Image

Examples

Embodiment 1

[0046] (1) Cut off the crop straw through pretreatment and dedust it, and then enter the separation section to separate hemicellulose, cellulose and lignin. Among them, the separation process produces a small amount of waste liquid, and the lignin stock solution is filtered to produce membrane treatment. Supernatant liquid and lignin, the separated hemicellulose is liquid phase, that is, hemicellulose liquid;

[0047] (2) The first liquid phase is obtained after the hemifiber liquid is mixed with a small amount of waste liquid, enters the waste water treatment system, and enters the sump through the grid machine;

[0048] (3) The first liquid phase in the sump passes through the sewage lifting pump and enters the microfilter to filter to obtain the second liquid phase;

[0049] (4) Add flocculant to the second liquid phase, and enter the first settling tank to settle to obtain the third liquid phase;

[0050] (5) The third liquid phase enters the pre-acidification tank, and n...

Embodiment 2

[0056] (1) Cut off the crop straw through pretreatment and dedust it, and then enter the separation section to separate hemicellulose, cellulose and lignin. Among them, the separation process produces a small amount of waste liquid, and the lignin stock solution is filtered to produce membrane treatment. Supernatant liquid and lignin, the separated hemicellulose is liquid phase, that is, hemicellulose liquid;

[0057] (2) The first liquid phase is obtained after the hemifiber liquid is mixed with a small amount of waste liquid, enters the waste water treatment system, and enters the sump through the grid machine;

[0058] (3) The first liquid phase in the sump passes through the sewage lifting pump and enters the microfilter to filter to obtain the second liquid phase;

[0059] (4) Add flocculant to the second liquid phase, and enter the first settling tank to settle to obtain the third liquid phase;

[0060] (5) The third liquid phase enters the pre-acidification tank, and n...

Embodiment 3

[0066] (1) Cut off the crop straw through pretreatment and dedust it, and then enter the separation section to separate hemicellulose, cellulose and lignin. Among them, the separation process produces a small amount of waste liquid, and the lignin stock solution is filtered to produce membrane treatment. Supernatant liquid and lignin, the separated hemicellulose is liquid phase, that is, hemicellulose liquid;

[0067] (2) The first liquid phase is obtained after the hemifiber liquid is mixed with a small amount of waste liquid, enters the waste water treatment system, and enters the sump through the grid machine;

[0068] (3) The first liquid phase in the sump passes through the sewage lifting pump and enters the microfilter to filter to obtain the second liquid phase;

[0069] (4) Add flocculant to the second liquid phase, and enter the first settling tank to settle to obtain the third liquid phase;

[0070] (5) The third liquid phase enters the pre-acidification tank, and n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com