Process for treating sewage by aeration tank

An aeration tank and sewage technology, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of polluting the environment and water environment, aggravating the shortage of water resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

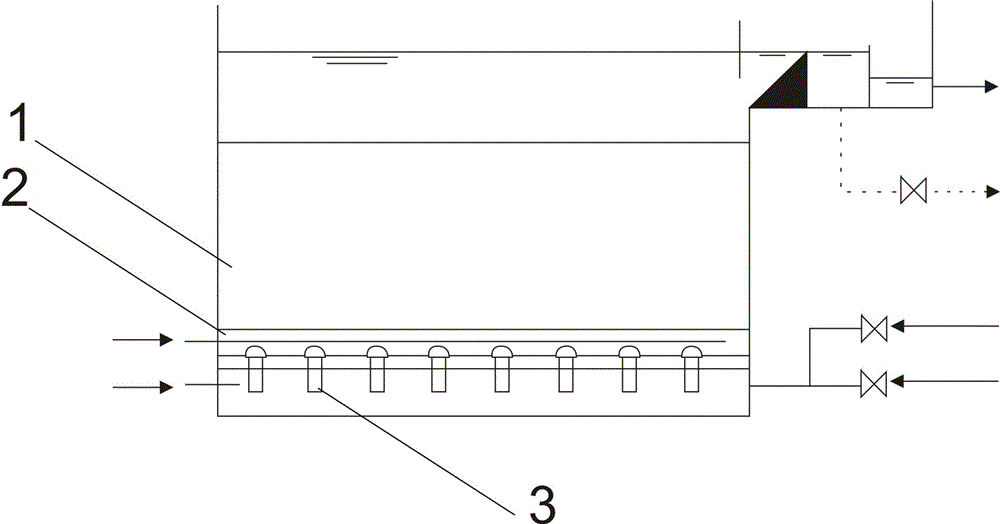

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0008] After the sewage passes through the grid 6 and the grit chamber 5, it enters the primary sedimentation tank 4 for preliminary settlement, and the effluent enters the first aeration tank 1 from the bottom to degrade BOD and COD and oxidize part of ammonia nitrogen; after the upward flow flows out, Enter the second aeration tank 2 from the bottom to degrade the remaining BOD and COD and completely oxidize ammonia nitrogen; then enter the third aeration tank 3 from the bottom, and the effluent from the third aeration tank flows back to the first aeration tank for Denitrification, while adding chemical phosphorus removal agent in the third aeration tank. By adding additional carbon sources (such as methanol, etc.) and chemical phosphorus removal agents (such as FeCl3, etc.) at the water inlet, denitrification and chemical phosphorus removal are carried out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com