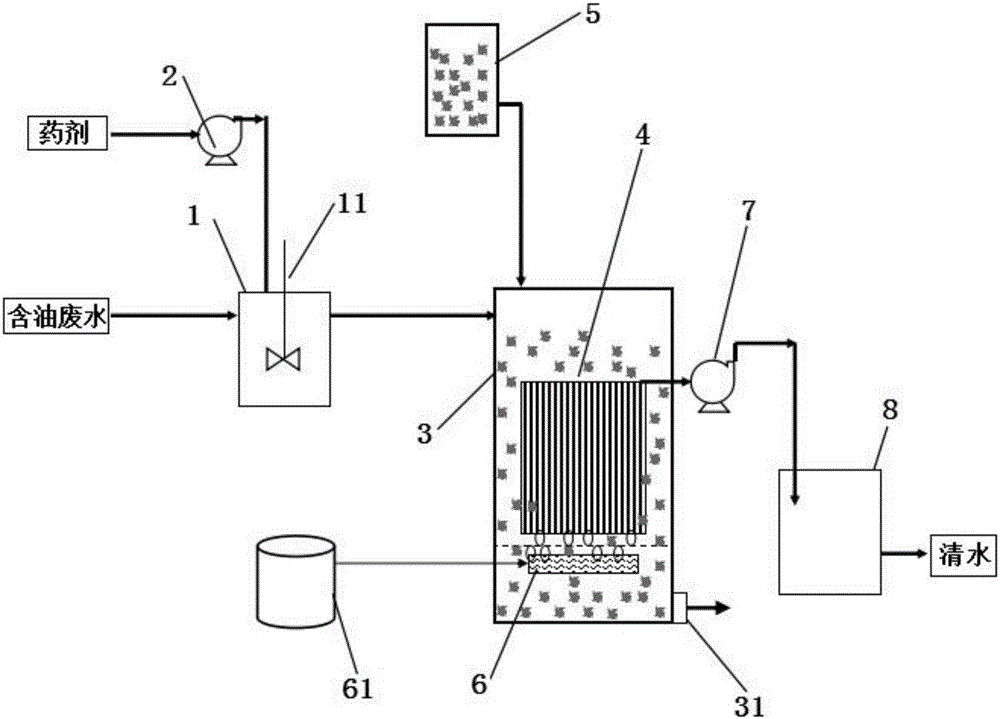

Oily wastewater treatment device and method

A technology for waste water and waste water ponds, applied in separation methods, grease/oily substances/suspton removal devices, water/sewage treatment, etc., can solve problems such as difficulty in meeting standard requirements, achieve surface pollution reduction, easy operation, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] In this example, the powdered activated carbon / ultrafiltration ceramic membrane method is used to treat oily wastewater, wherein the water quality parameters of the oily wastewater introduced are: oil concentration: 112.70mg / L, turbidity: 9.23NTU; SS (suspended) after adding powdered activated carbon Particles) content is 45mg / L. The operating conditions of the ceramic membrane are: the initial transmembrane pressure difference is 4.4kPa, and the membrane flux is 60L / m 2 h; The dosage of powdered activated carbon is: 45mg / L.

[0037]At the processing time of 1, 5, 10, 20, 30, 40, 50, 60, 70, 80, 90, 100, 110, and 120 minutes, the detected oil concentration in water was 1.28, 1.15, 1.22, 1.06, 0.95, 0.96, 0.95, 0.97, 0.90, 0.93, 0.84, 0.79, 0.84, 0.89mg / L.

[0038] From the above test results, it can be seen that the oil concentration of the water sucked by the suction pump detected after half an hour is lower than 1mg / L, and the turbidity is always less than 0.2NTU, w...

example 2

[0040] In this example, the powdered activated carbon / ultrafiltration ceramic membrane method is used to treat oily wastewater. The water quality parameters of the oily wastewater introduced are: oil concentration: 112.50mg / L, turbidity: 9.17NTU; SS content after adding powdered activated carbon 60mg / L. The operating conditions of the ceramic membrane are: the initial transmembrane pressure difference is 4.7kPa, and the membrane flux is 60L / m 2 h; The dosage of powdered activated carbon is: 60mg / L.

[0041] At the processing time of 1, 5, 10, 20, 30, 40, 50, 60, 70, 80, 90, 100, 110, 120min, the detected water and oil concentrations were: 0.34, 0.36, 0.42, 0.37, 0.37, 0.34, 0.33, 0.41, 0.35, 0.34, 0.40, 0.42, 0.40, 0.38mg / L, all lower than 1mg / L, turbidity <0.15NTU, and the increase of transmembrane pressure difference after filtration for 2h was 0.2kPa.

[0042] It can be seen from the above test results that the clear water treated by the method of this example also fully ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com