Environmental-friendly healthy automobile foot mat capable of generating anions

A technology of car mats and negative ions, applied in the field of car mats, can solve the problems of easy cracking and aging, not paying attention to use functions, and short service life, so as to delay cracking and aging, enhance human immunity, and avoid traffic accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

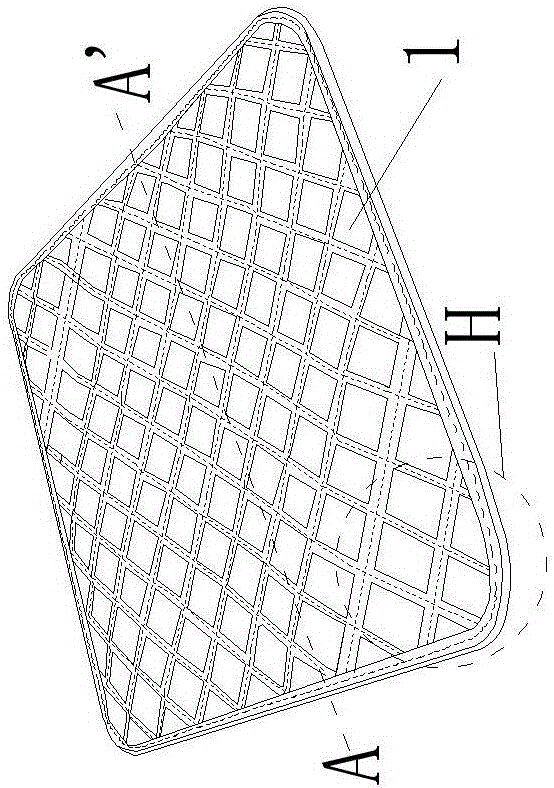

[0049] Example 1. Such as Figure 1-Figure 6As shown, an environmentally friendly and healthy car floor mat capable of generating negative ions includes a floor mat unit, and the floor mat unit includes a top wear-resistant soft layer 1 and a negative ion plastic stone plate hard layer 2 that can release negative ions from top to bottom. The top wear-resistant soft layer 1 is a composite layer of leather layer 3 or leather layer 3 and the elastic layer 4 below it; the thickness of the negative ion plastic stone plate hard layer 2 that can release negative ions is 2-10mm; the top wear-resistant soft layer The thickness of the layer 1 is 1-5mm, and the weight of the car mat is kept at 1000-3000g / square meter to improve the anti-skid stability of the cushion; the leather is animal leather or artificial leather; the artificial leather is pvc artificial leather or PU Synthetic Leather. The elastic layer is a laminate made of sponge.

[0050] Negative ion materials, as one of the...

Embodiment 2

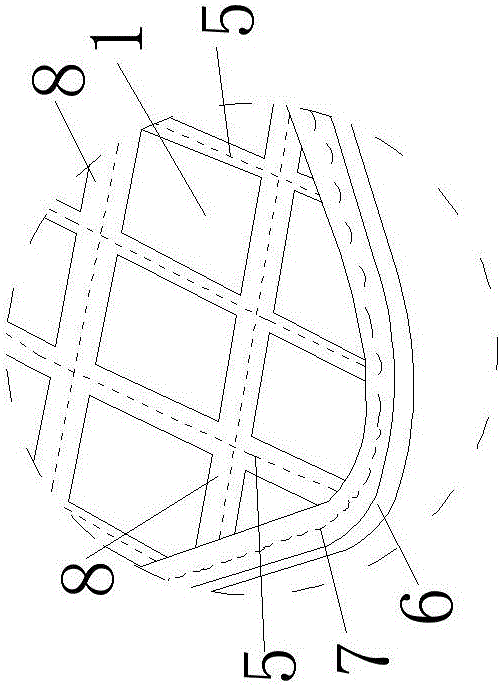

[0066] Example 2. Such as Figure 7-Figure 10 As shown, the difference between this embodiment and embodiment 1 is that the elastic layer is a layer made of sponge. The edge of the top wear-resistant soft layer 1 covers the edge of the negative ion plastic stone plate hard layer 2 and extends to the bottom surface of the negative ion plastic stone plate hard layer 2; The two are stitched together by the second suture thread 7. Each component of the negative ion plastic stone plate hard layer is as follows by weight: 15 parts of calcium oxide, 50 parts of silicon dioxide, 8 parts of calcium magnesium tourmaline, 13 parts of black tourmaline, 3 parts of monazite, 5 parts of calcium stearate, Magnesium oxide 0.3 parts, plastic 50 parts.

[0067] Its production process is as follows:

[0068] (1) Ingredients according to the formula of raw materials;

[0069] (2) After adding the prepared raw materials into the mixer, run it at a low speed, add a heat stabilizer, and increase...

Embodiment 3

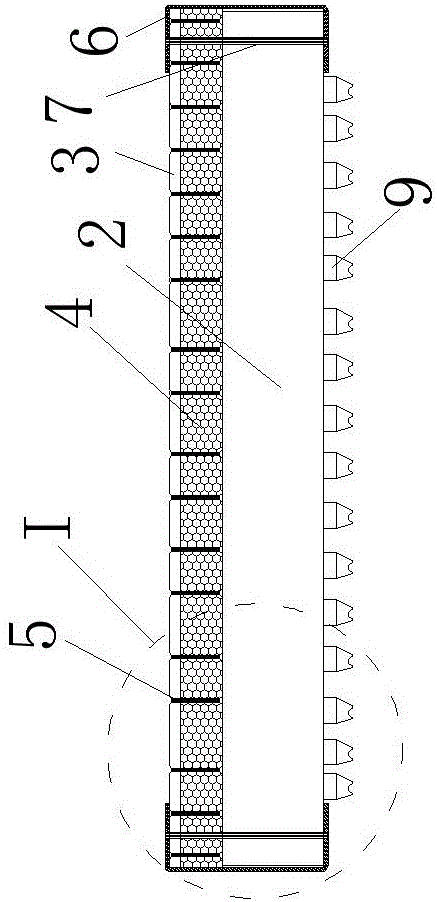

[0074] Example 3. Such as Figure 11-Figure 13 As shown, the difference between the present embodiment and the embodiment 1 is that the elastic layer is a laminate made of silicone foam. The bottom of the hard layer 2 of negative ion molded stone slab is provided with anti-slip ribs 12 . Each component of the negative ion plastic stone plate hard layer is as follows by weight: 10 parts of calcium oxide, 30 parts of silicon dioxide, 5 parts of calcium magnesium tourmaline, 10 parts of black tourmaline, 2 parts of monazite, 3 parts of calcium stearate, 1 part of magnesium oxide, 180 parts of plastic.

[0075] Its production process is as follows:

[0076] (1) Ingredients according to the formula of raw materials;

[0077] (2) After adding the prepared raw materials into the mixer, run it at a low speed, add a heat stabilizer, and increase the mixer to a high speed;

[0078] (3) Add plasticizers, foaming agents, and coupling agents below 55°C; plasticizers are aliphatic diba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com