A method and mold for preparing pavement composite pasting block

A mold and pavement technology, which is applied in the field of preparing pavement combined paste blocks, can solve problems such as pavement damage, insufficient durability, and complex process of colored pavement materials, and achieve the effects of speeding up construction, optimizing construction methods, and avoiding pavement damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

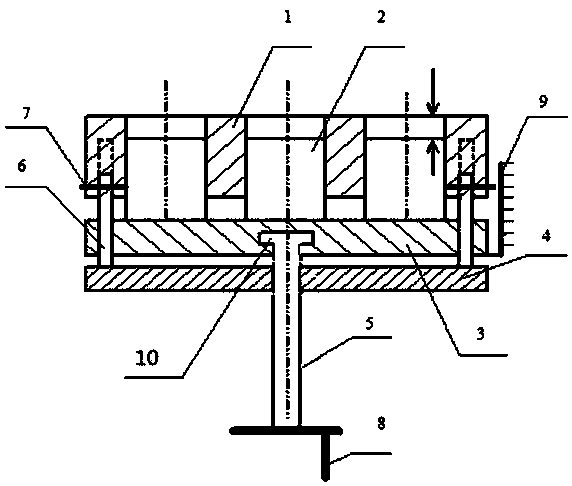

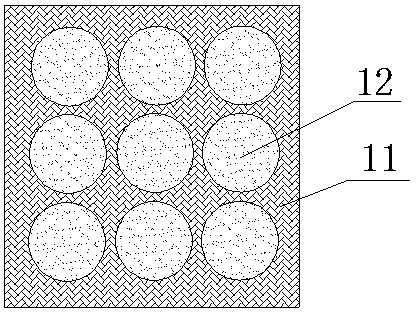

[0076] The mold of the pavement combination sticking block of this embodiment is provided with nine mold cores 2 arranged in 3 rows and 3 columns, and the shapes of the mold holes and the mold cores are circular. The orifice area of the die hole is 80cm 2 , The thickness of the template is 30mm, the length of the core 2 extending into the die hole is 10mm, and the distance between two adjacent die holes is 2mm. The design template 1, the fixed plate 3, and the bottom plate 4 are all square, and the connecting rods 6 are each provided at the four corners of the bottom plate. See above for other structures.

Embodiment 2-5

[0077] Example 2-5: Preparation of cement

[0078] Cementing materials were prepared according to the materials and compositions shown in Table 1, and cementing materials A1, A2, A3, and A4 were obtained corresponding to Examples 2-5.

[0079] Table 1 Binder composition and formula

[0080] Example 2 Example 3 Example 4 Example 5 A1A2A3A4 Epoxy resin model and parts by weightE-51,100E-44,100E-42,100E-42,100 Curing agent model and weight parts YH-82, 20 YH-82, 40 YH-82, 50 YH-82, 30 Toughener materials and parts by weight Polypropylene glycol diglycidyl ether, 40 Benzyl alcohol, 20 Polypropylene glycol diglycidyl ether, 10 Polypropylene glycol diglycidyl ether, 30

Embodiment 6

[0082] Add 10kg alumina powder, 0.75kg calcium carbonate powder, 0.1kg dye (iron oxide red) into 20kg water, ball mill for 4h to obtain the first slurry, and then add the first slurry to 200kg of alginic acid with a concentration of 1.5wt% In the sodium solution, stir evenly to form a second slurry with a solid phase content of 4.7%, where the solid phase content in the second slurry = solid phase powder mass / total slurry weight, solid phase powder mass = alumina powder mass + Calcium carbonate powder quality + dye quality, total slurry weight = solid phase powder quality + sodium alginate solution quality.

[0083] Add 2.5 kg of gluconolactone powder to the second slurry, then stir it evenly, and let it stand at 40°C for 48 hours to obtain the first gel. Among them, because the gluconolactone powder slowly releases H from the mouth + Therefore, there is no obvious gel phenomenon during the stirring process, but the gel is gradually formed in the static process, so as to ensure t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com