Nuclear power fuel assembly tube socket laser additional material forming manufacturing method

A fuel assembly, laser additive technology, applied in additive manufacturing, additive processing, process efficiency improvement, etc., can solve problems such as difficulty, complicated procedures, and long process development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

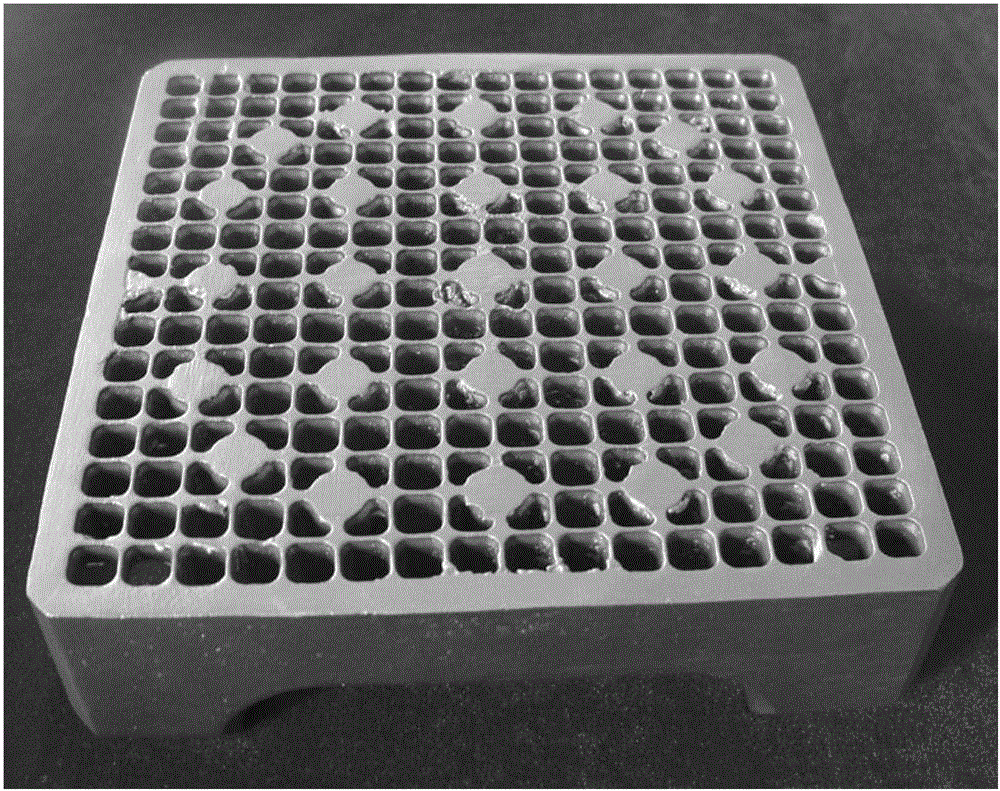

Image

Examples

Embodiment 1

[0025] A method for manufacturing nuclear power fuel assembly sockets by laser additive molding according to the present invention comprises the following steps:

[0026] Step 1) Carry out three-dimensional model design on the drawing of the pipe seat, and design it into a three-dimensional solid model; the software used for the three-dimensional model design is Pro / E.

[0027] Step 2) Perform 45° solid support treatment on the suspended position of the model obtained in step 1); the suspended position refers to that during the bottom-up layer-by-layer molding process of the pipe seat, some positions are not between the previous layer section and the subsequent layer section. Areas with overlapping dimensions greater than 2mm.

[0028] Step 3) slice the model obtained in step 2) into layers according to a certain thickness; design the laser power, laser scanning speed and laser scanning distance parameters of the parts in each slice; wherein, the layer thickness is 0.05mm, and...

Embodiment 2

[0035] A method for manufacturing nuclear power fuel assembly sockets by laser additive molding according to the present invention comprises the following steps:

[0036] Step 1) Carry out three-dimensional model design on the drawing of the pipe seat, and design it into a three-dimensional solid model; the software used for the three-dimensional model design is UG.

[0037] Step 2) Add support to the suspended position of the model obtained in step 1); the suspended position refers to the part of the position that does not overlap between the section of the previous layer and the section of the next layer during the bottom-up molding process of the pipe seat Areas with dimensions greater than 2 mm.

[0038] Step 3) Slice the model obtained in step 2) in layers according to a certain thickness; design the laser power, laser scanning speed and laser scanning spacing parameters of the parts in each slice; the layer thickness is 0.04mmmm, the laser power is 220W, the laser The s...

Embodiment 3

[0046] A method for manufacturing nuclear power fuel assembly sockets by laser additive molding according to the present invention comprises the following steps:

[0047] Step 1) Carry out three-dimensional model design on the drawing of the pipe seat, and design it into a three-dimensional solid model; the software used for the three-dimensional model design is Solidwork.

[0048] Step 2) Add support to the suspended position of the model obtained in step 1); the suspended position refers to the part of the position that does not overlap between the section of the previous layer and the section of the next layer during the bottom-up molding process of the pipe seat Areas with dimensions greater than 2 mm.

[0049] Step 3) slice the model obtained in step 2) into layers according to a certain thickness; design the laser power, laser scanning speed and laser scanning distance parameters of the parts in each slice; the layer thickness is 0.06mm, the laser power is 260W, the lase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com