Catalyst for preparation of styrene and ethylbenzene by side chain alkylation reaction of toluene and application thereof

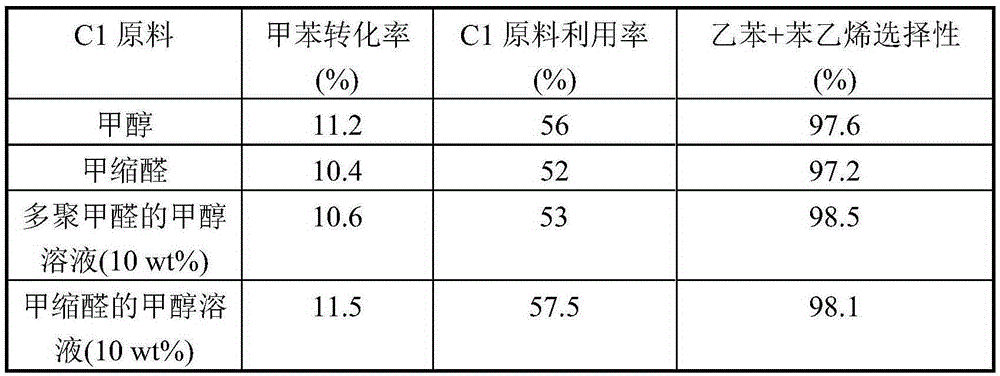

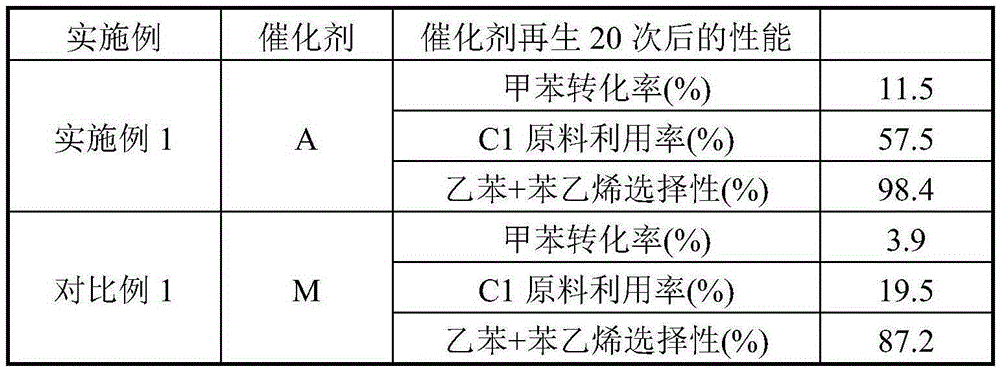

An alkylation reaction, styrene technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low utilization rate of C1 raw materials, low toluene conversion rate, poor catalyst stability, etc. The effect of high C1 raw material utilization, high toluene conversion and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 100g silicon aluminum ratio SiO 2 / Al 2 o 3For 2.1 NaX molecular sieves, at 60°C, carry out ion exchange in 500mL of potassium nitrate aqueous solution for 2 hours, exchange twice, then at 60°C, carry out ion exchange in 500mL of cesium nitrate aqueous solution for 2 hours, exchange 2 times, exchanged, filtered, and dried in an oven at 110°C for 4 hours. Prepare 100 mL of an aqueous solution containing an appropriate amount of sodium metaaluminate, rhenium chloride, calcium nitrate, and cerium nitrate, impregnate the ion-exchanged molecular sieve in the above solution by stirring for 4 hours at 60°C, and then evaporate to dryness. Dry in an oven at 110°C for 4 hours, and then bake in a muffle furnace at 600°C for 4 hours to obtain catalyst A, which is ground into 40-60 mesh particles for catalyst evaluation. The mass ratio of the modifying elements contained in the catalyst A to the molecular sieve carrier is: Al 1%, Re 0.6%, K 2%, Cs 8%, Ca 0.8%, Ce 1%.

Embodiment 2

[0025] Weigh 100g silicon aluminum ratio SiO 2 / Al 2 o 3 For NaX molecular sieves of 2, ion exchange was carried out in 500 mL aqueous solution of potassium nitrate at 60 °C for 2 hours, exchanged twice, and then at 60 °C, ion exchange was carried out in 500 mL aqueous solution of cesium nitrate for 2 hours, exchanged 2 times, exchanged, filtered, and dried in an oven at 90°C for 24 hours. Prepare 100 mL of an aqueous solution containing an appropriate amount of sodium metaaluminate, rhenium chloride, calcium nitrate, and cerium nitrate, impregnate the ion-exchanged molecular sieve in the above solution by stirring for 4 hours at 60°C, and then evaporate to dryness. Dry in an oven at 90°C for 24 hours, and then bake in a muffle furnace at 400°C for 24 hours to obtain catalyst B, which is ground into 40-60 mesh particles for catalyst evaluation. The mass ratio of the modifying elements contained in the catalyst B to the molecular sieve carrier is: Al 1%, Re 0.6%, K 0.5%, Cs ...

Embodiment 3

[0027] Weigh 100g silicon aluminum ratio SiO 2 / Al 2 o 3 For 2.9 NaX molecular sieves, at 60°C, carry out ion exchange in 500mL of potassium nitrate aqueous solution for 2 hours, exchange twice, then at 60°C, carry out ion exchange in 500mL of cesium nitrate aqueous solution for 2 hours, exchange 2 times, exchanged, filtered, and dried in an oven at 150°C for 1 hour. Prepare 100 mL of an aqueous solution containing an appropriate amount of sodium metaaluminate, rhenium chloride, calcium nitrate, and cerium nitrate, impregnate the ion-exchanged molecular sieve in the above solution by stirring for 4 hours at 60°C, and then evaporate to dryness. Dry in an oven at 150°C for 1 hour, and then bake in a muffle furnace at 650°C for 1 hour to obtain catalyst C, which is ground into 40-60 mesh particles for catalyst evaluation. The mass ratio of the modifying elements contained in the catalyst C to the molecular sieve carrier is: Al 1%, Re 0.6%, K 10%, Cs 10%, Ca 2%, Ce 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com