ZnO-CdS composite material and preparation method and application of ZnO-CdS composite material

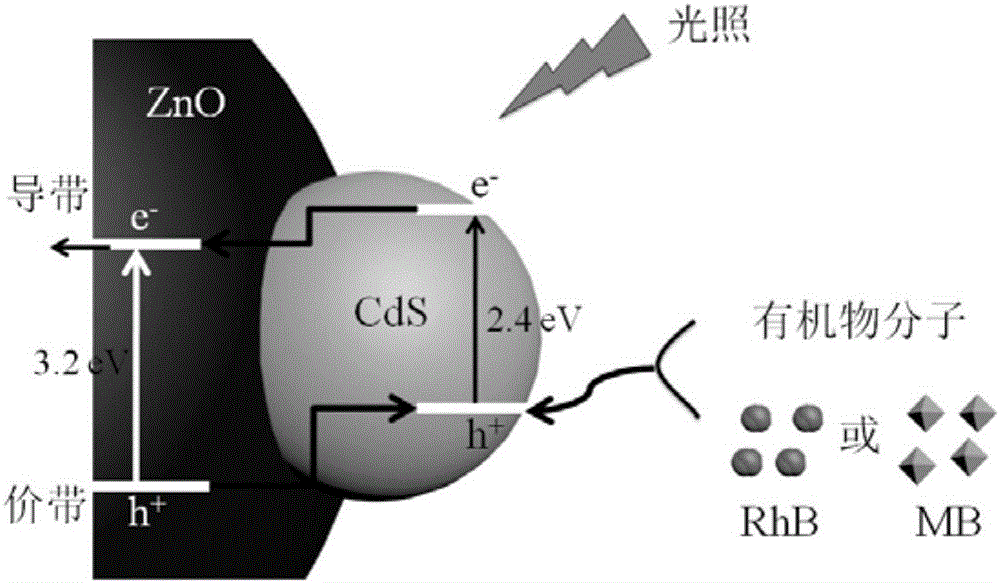

A composite material, zno-cds technology, applied in the direction of chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problem of limiting the use of general light sources and the inability to effectively improve the light source utilization rate. The photodegradation ability of chemical substances, etc. problem, achieve the effect of increasing the light absorption range, facilitating separation, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

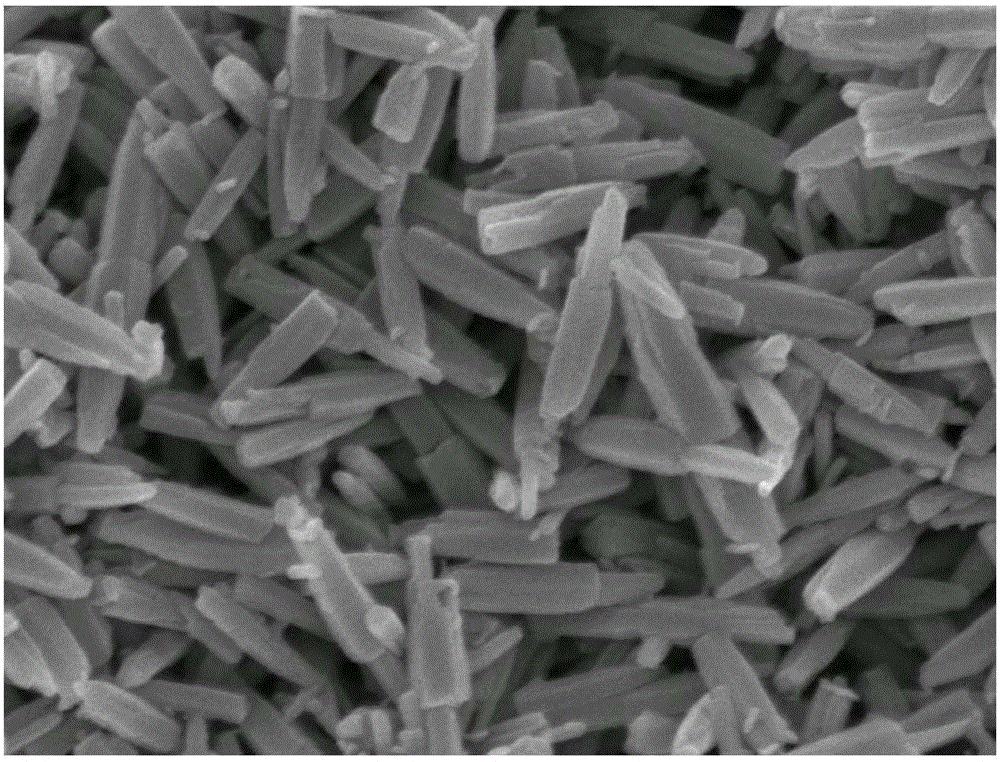

[0032] 1.4875g of Zn(NO 3 ) 2 ·6H 2 O dissolved in 20 mL deionized water, 0.7408 g NH 4 Dissolve F in 10mL deionized water, and dissolve 0.8002g NaOH in 10mL deionized water. By adding Zn(NO 3 ) 2 ·6H 2 O deionized water and NH 4 F deionized aqueous solution was mixed to obtain a precursor solution, and then NaOH deionized aqueous solution was added dropwise. When a small amount of NaOH deionized water solution was added dropwise, a white precipitate formed immediately, and after further adding all the remaining NaOH deionized water solution dropwise, part of it dissolved and the solution became translucent. It was then clouded for 10 hours at 50°C with constant stirring. The white precipitate was harvested by centrifugation, washed with deionized water and ethanol, and finally dried at 60°C overnight to obtain ZnO nanoparticles;

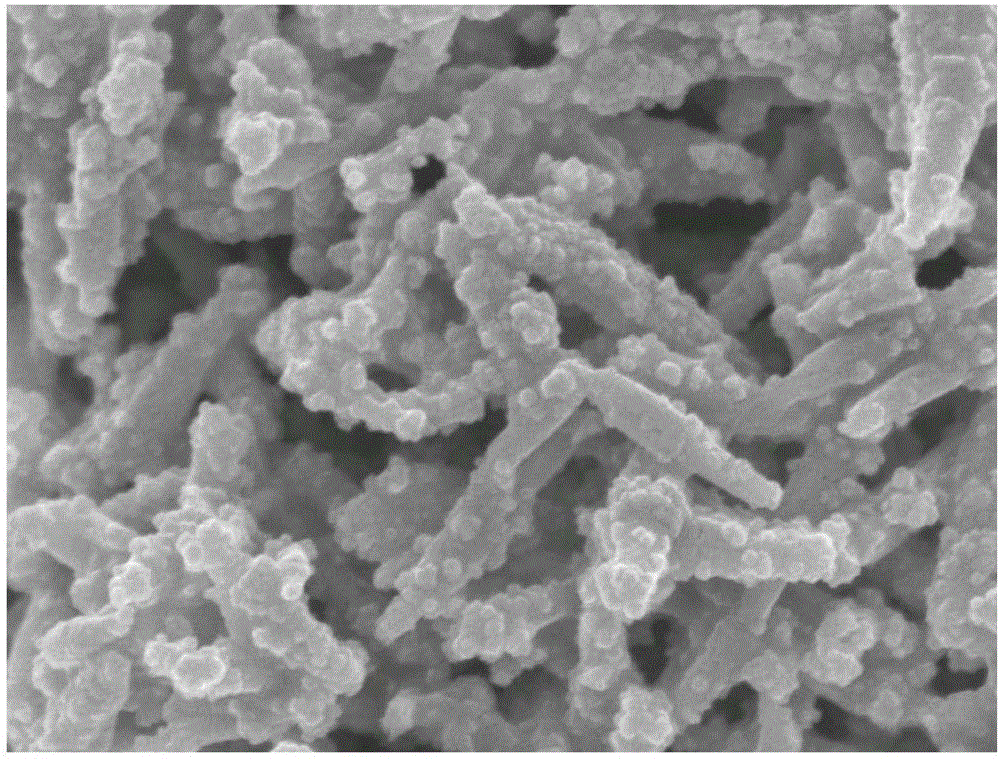

[0033] 0.2364g Cd(NO 3 ) 2 4H 2 O and 0.0761 g of thiourea were dissolved in 100 mL of deionized water and mixed with 40 mg of ZnO nano...

Embodiment 2

[0047] The prepared ZnO-CdS was used to degrade rhodamine B

[0048] Take 100ml of rhodamine B solution with a concentration of 8μg / ml in a container, add 10mg of ZnO-CdS and stir in the dark for 1 hour. Then irradiate under a 300W xenon lamp, start sampling from 0 minutes, take samples every 5 minutes, take 8 samples, then take samples every 10 minutes, take two samples, and finally take samples every 20 minutes, take three samples.

[0049] The samples taken were subjected to ultraviolet detection in turn, and the results were as follows: Figure 5 shown.

Embodiment 3

[0051] The prepared ZnO-CdS was used to degrade methylene blue

[0052] Take 100ml of methylene blue solution with a concentration of 8μg / ml in a container, add 10mg of ZnO-CdS and stir in the dark for 1 hour. Then irradiate under a 300W xenon lamp, start sampling from 0 minutes, take samples every 5 minutes, take 8 samples, then take samples every 10 minutes, take two samples, and finally take samples every 20 minutes, take three samples.

[0053] The samples taken were subjected to ultraviolet detection in turn, and the results were as follows: Image 6 shown.

[0054] pass Figure 5 with Image 6 It can be observed that the characteristic peaks of rhodamine B and methylene blue have both decreased significantly, which proves that ZnO-CdS nanomaterials have a significant degradation effect on rhodamine B and methylene blue under light conditions, so the material has enhanced light Degradability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com