Heat-clearing and detoxifying Zen-food coarse cereal premix powder and production method thereof

A heat-clearing and detoxifying, production method technology, applied in the direction of dough/premix, food science, baking mixture, etc., can solve the problems of unseen research, development and production of functional food, unsuitable for large-scale population, rough taste, etc. , to achieve the effect of improving the shelf life of the taste, avoiding heavy metal residues, and having a delicate and smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

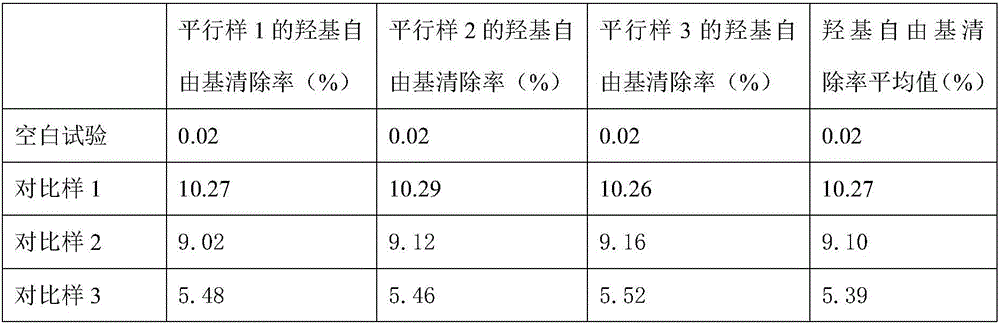

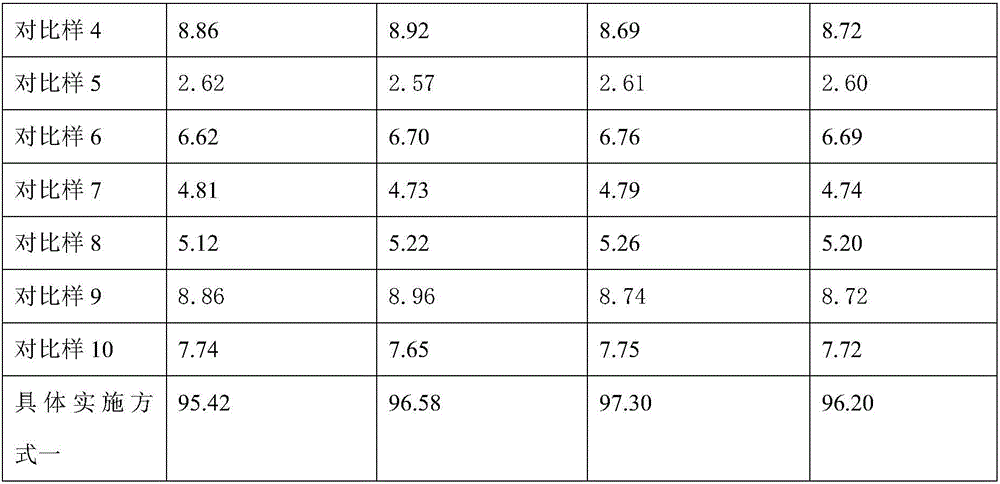

[0021] Specific embodiment 1: In this embodiment, the premixed powder of Zen miscellaneous grains for clearing away heat and detoxifying is made from the following raw materials in parts by weight: 10 parts of green beans, 10 parts of mung beans, 10 parts of barley, 10 parts of broad beans, and 10 parts of red beans. Servings, 5 servings of licorice, 5 servings of tangerine peel, 5 servings of red adzuki beans, 5 servings of gardenia, 10 servings of soybean fiber powder, 5 servings of cereal powder, 0.2 servings of baking soda, 0.2 servings of ammonium bicarbonate, 0.4 servings of gluconolactone, single 0.2 parts of glycerides.

[0022] The coarse grains and Chinese herbal medicine raw materials in the above raw materials are respectively subjected to the pretreatment of selection, washing and drying in sequence; the drying is carried out in a drying box at a drying temperature of 45°C, and the drying is stopped after the moisture content of the coarse grains and Chinese herbal me...

specific Embodiment approach 2

[0029] Specific embodiment two: this embodiment is different from specific embodiment one in that: the premixed powder of Zen food for clearing away heat and detoxifying is made from the following raw materials in parts by weight ratio: 8 parts of green beans, 8 parts of mung beans, and 10 parts of barley. Servings, 8 servings of broad beans, 5 servings of red beans, 10 servings of licorice, 10 servings of tangerine peel, 5 servings of red adzuki beans, 5 servings of gardenia, 20 servings of soybean fiber powder, 5 servings of cereal powder, 0.3 servings of baking soda, 0.2 servings of ammonium bicarbonate, 0.5 part of gluconolactone and 0.3 part of monoglyceride. The other steps and parameters are the same as in the first embodiment.

[0030] The method of making cookies with premixed powder in this embodiment: Take 80 parts by weight of premixed powder prepared by the method of this embodiment, and add 80 parts of low-gluten flour to mix, sieving, and set aside. Take 60 parts ...

specific Embodiment approach 3

[0031] Specific embodiment three: this embodiment is different from specific embodiment one in that: the premixed powder of Zen miscellaneous grains for clearing away heat and detoxifying is made from the following raw materials in parts by weight: 8 parts of green beans, 10 parts of mung beans, and 10 parts of barley. Servings, 10 servings of broad beans, 10 servings of red beans, 5 servings of licorice, 10 servings of tangerine peel, 5 servings of red adzuki beans, 10 servings of gardenia, 10 servings of soybean fiber powder, 5 servings of grain flour, 0.2 servings of baking soda, 0.2 servings of ammonium bicarbonate, 0.4 parts of gluconolactone and 0.3 parts of monoglyceride. The other steps and parameters are the same as in the first embodiment.

[0032] In this embodiment, the method of making cookies with pre-mixed powder is to take 100 parts of the pre-mixed powder produced by the method of this embodiment in parts by weight, add 90 parts of low-gluten flour to mix, sievin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com