Ecological restoration method of solid waste yards

A technology for solid waste and ecological restoration, applied in solid waste removal, botany equipment and methods, plant cultivation, etc., can solve surface water and groundwater pollution, ecological environment damage, damage to land, natural landscape and vegetation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

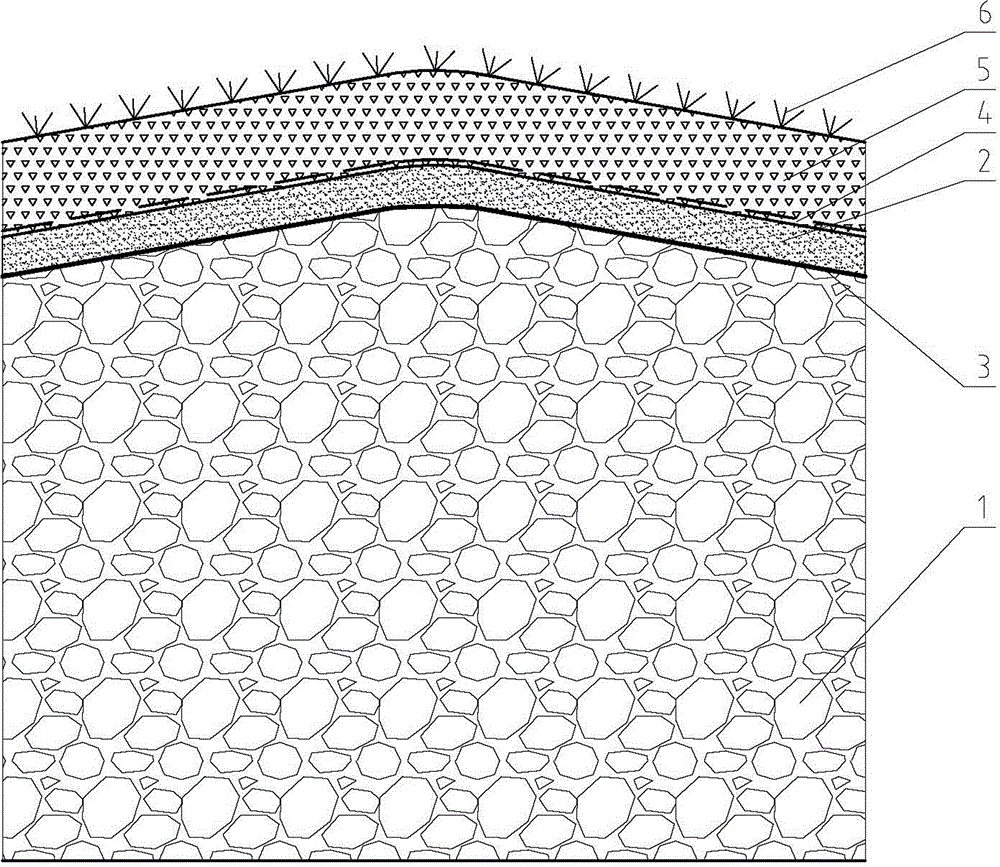

[0017] Depend on figure 1 It can be seen that a method for ecological restoration of a solid waste dump site comprises the following steps:

[0018] (1) Mix the solid waste in the storage yard with fixative and water evenly, and roll and compact it;

[0019] ⑵In the process of compaction, make the central position of the stacking yard the high point, and gradually incline towards the periphery with a slope of 5°<slope<45°;

[0020] (3) Place an anti-seepage layer on the compacted solid waste, and pile clay with a thickness of 10cm to 20cm on the anti-seepage layer for compaction;

[0021] ⑷Pile a sand layer with a thickness of 1cm to 3cm on the compacted clay and compact it;

[0022] (5) Lay cultivation soil with a thickness of 30cm to 45cm on the compacted sand layer, and plant saplings or grass seedlings on the cultivation soil.

[0023] The anti-seepage layer of the present invention is non-woven fabric or waterproof blanket.

[0024] In this embodiment, firstly, the so...

Embodiment 2

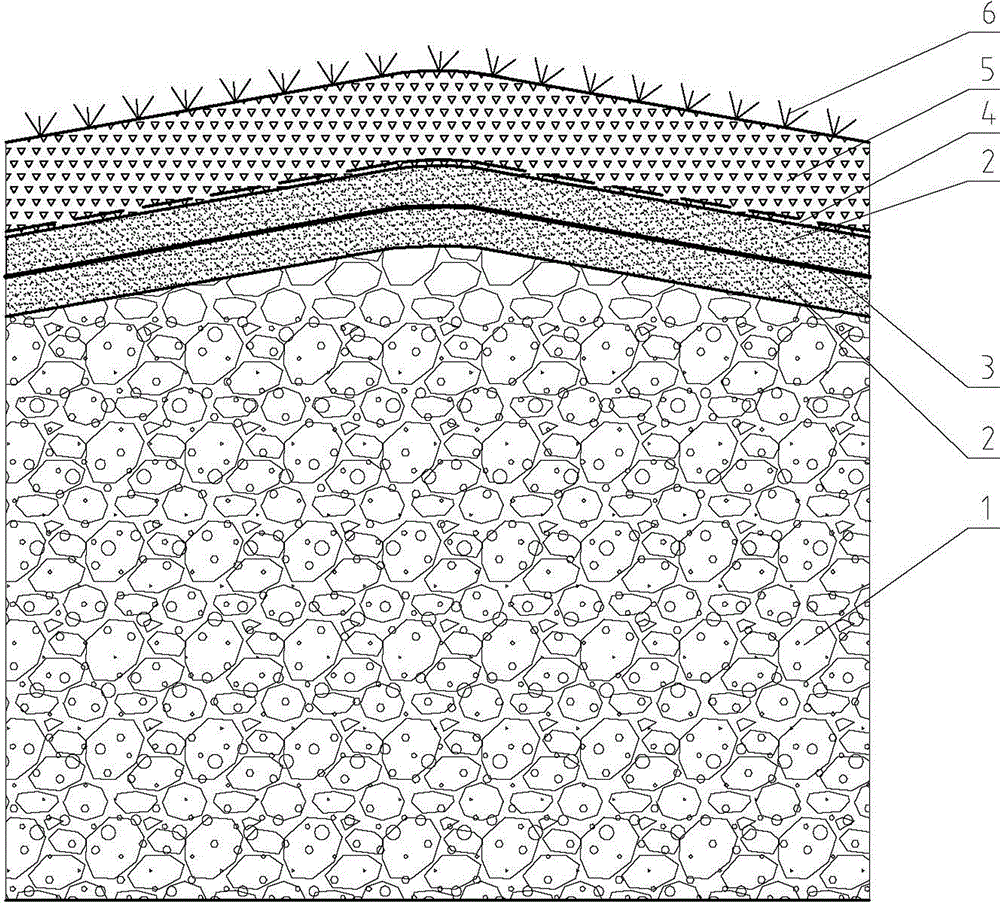

[0030] Depend on figure 2 It can be seen that in order to prevent the anti-seepage layer 3 from moving on the solid waste 1, in the step (3) of the present invention, firstly, the clay 2 with a thickness of 10 cm to 20 cm is stacked on the compacted solid waste 1 and compacted; Place the anti-seepage layer 3, and then pile up the clay 2 with a thickness of 10cm to 20cm on the anti-seepage layer 3, and compact it.

[0031] The anti-seepage layer 3 of this embodiment adopts a waterproof blanket, and the waterproof blanket is a bentonite waterproof blanket, which is made of graded natural sodium bentonite particles and corresponding admixtures mixed as raw materials. A blanket-like waterproofing membrane fixed between geotextiles and plastic woven fabrics. Bentonite waterproof blanket not only has all the characteristics of geotechnical materials, but also has excellent waterproof (seepage) performance.

[0032] In this way, the anti-seepage layer 3 is difficult to move on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com