Portable spiral backpack punching machine

A punching machine, portable technology, applied in the direction of excavation/covering of trenches, agriculture, application, etc., can solve the problems of small size, low production efficiency, high labor intensity, etc., to achieve good operability, improve position accuracy and cost. Hole effect, the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

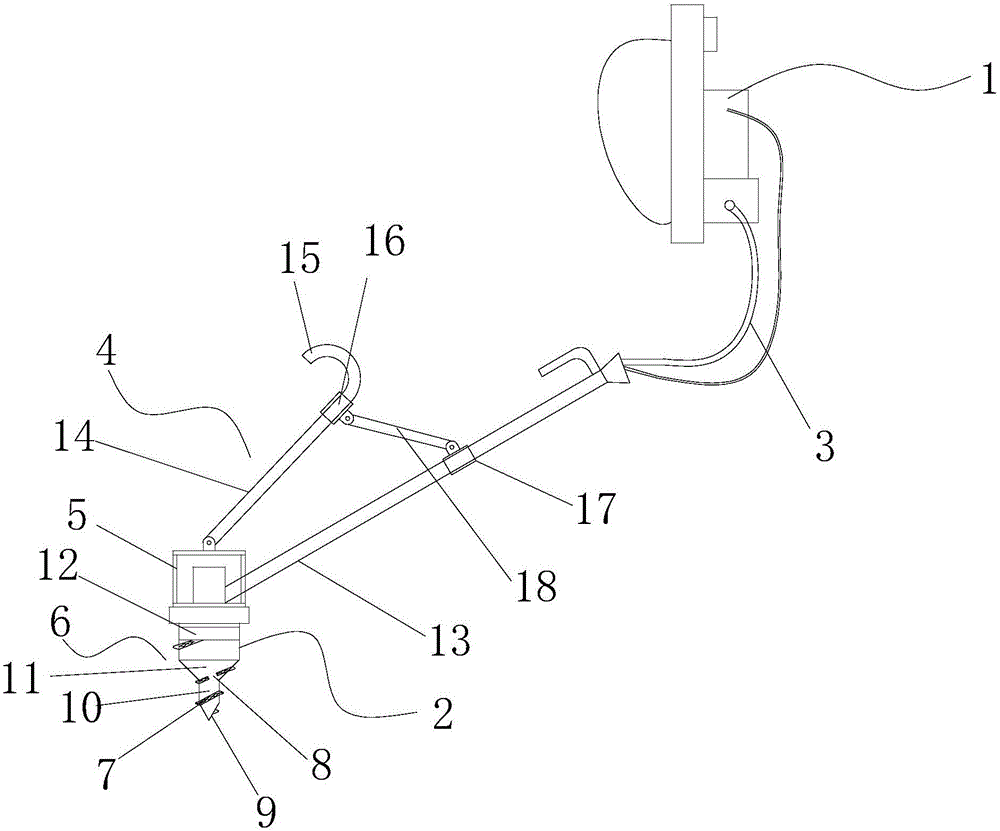

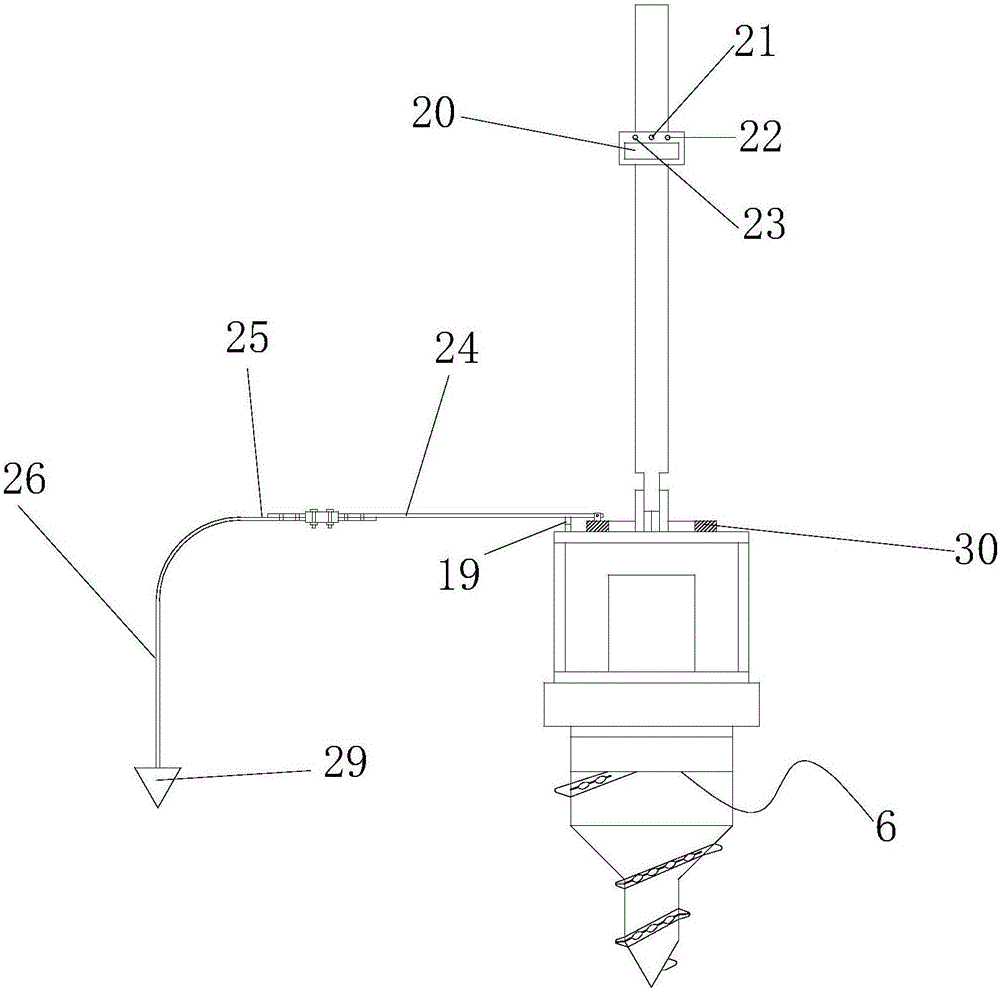

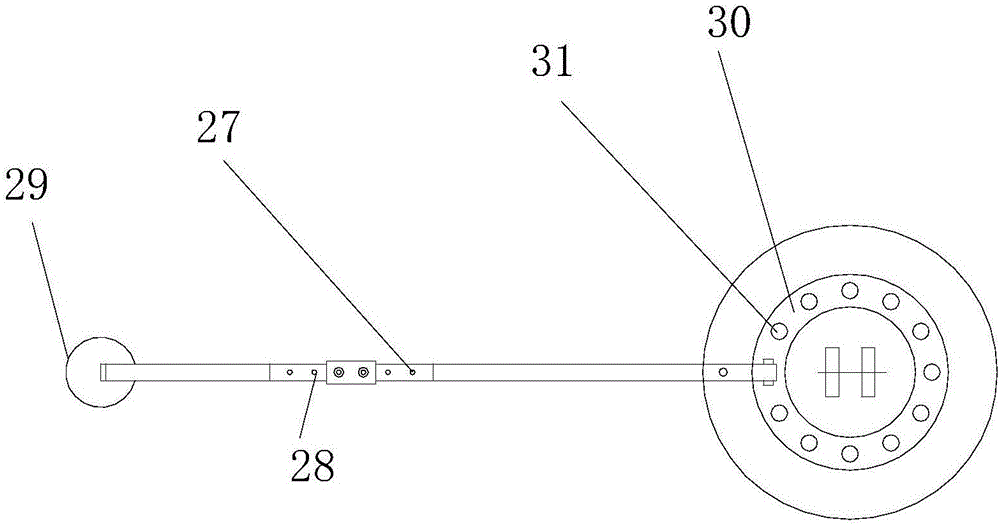

[0024] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a partial structure schematic diagram of the present invention, image 3 It is the top view of the drill bit assembly in the present invention, Figure 4 It is a functional block diagram of the circuit control of the present invention, as shown in the figure, the portable screw punching machine in the present embodiment; includes a power unit 1, a drill assembly 2, and a transmission connected between the power unit 1 and the drill assembly 2 The flexible shaft 3 and the operating assembly 4 used to control the drill assembly 2; the power unit 1 is used as an energy supply device to provide the drill assembly 2 with the required speed and torque during work, and the transmission flexible shaft 3 is the power transmission link of the entire device. The power unit 1 and the transmission flexible shaft 3 can adopt the existing structure, which will not be repeated here;

[0025] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com