A front collimator for ct

A pre-collimator and collimator technology, applied in the field of particle or ionizing radiation processing, can solve the problems of increasing the collimation slit width, image quality degradation, image artifacts, etc., to achieve uniform width and work efficiency. High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

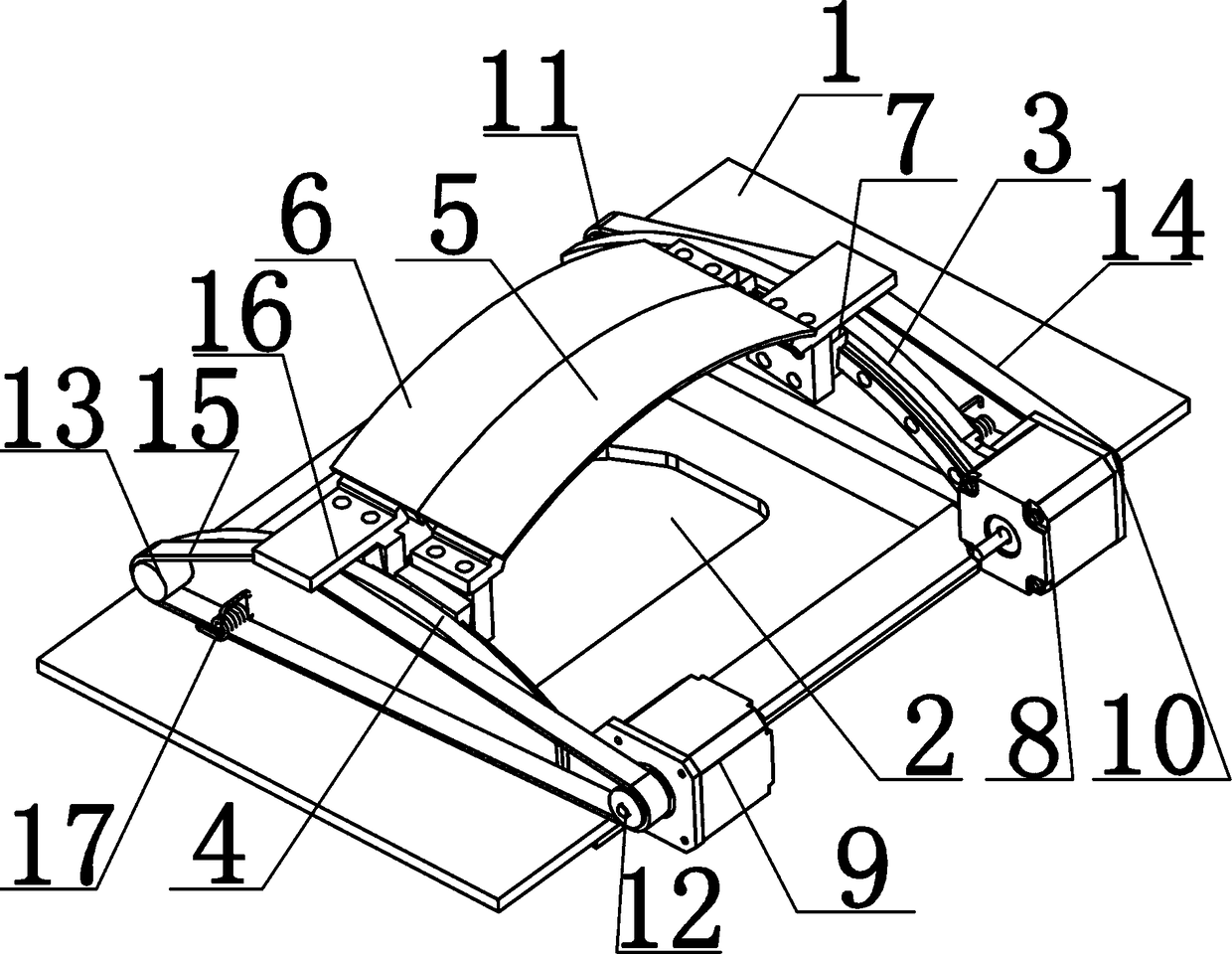

[0034]The transmission mechanism includes a first driving wheel 10 and a first driven wheel 11, a second driving wheel 12 and a second driven wheel 13 which are set in cooperation, and the first driving wheel 10 and the second driving wheel 12 are respectively arranged on the first On the motor shafts of the motor 8 and the second motor 9, the first motor 8 and the second motor 9 are respectively arranged on the front end of the case cover 1 on the left side and the right side of the through hole 2, and the first driven wheel 11 and the second The two driven wheels 13 are respectively arranged on the rear end of the case cover 1 on the left side and the right side of the through hole 2, and the outer sides of the first driving wheel 10 and the first driven wheel 11 are provided with a first synchronous belt 14. The outer sides of the two driving wheels 12 and the second driven wheel 13 are provided with a second synchronous belt 15, and the first synchronous belt 14 and the sec...

Embodiment 2

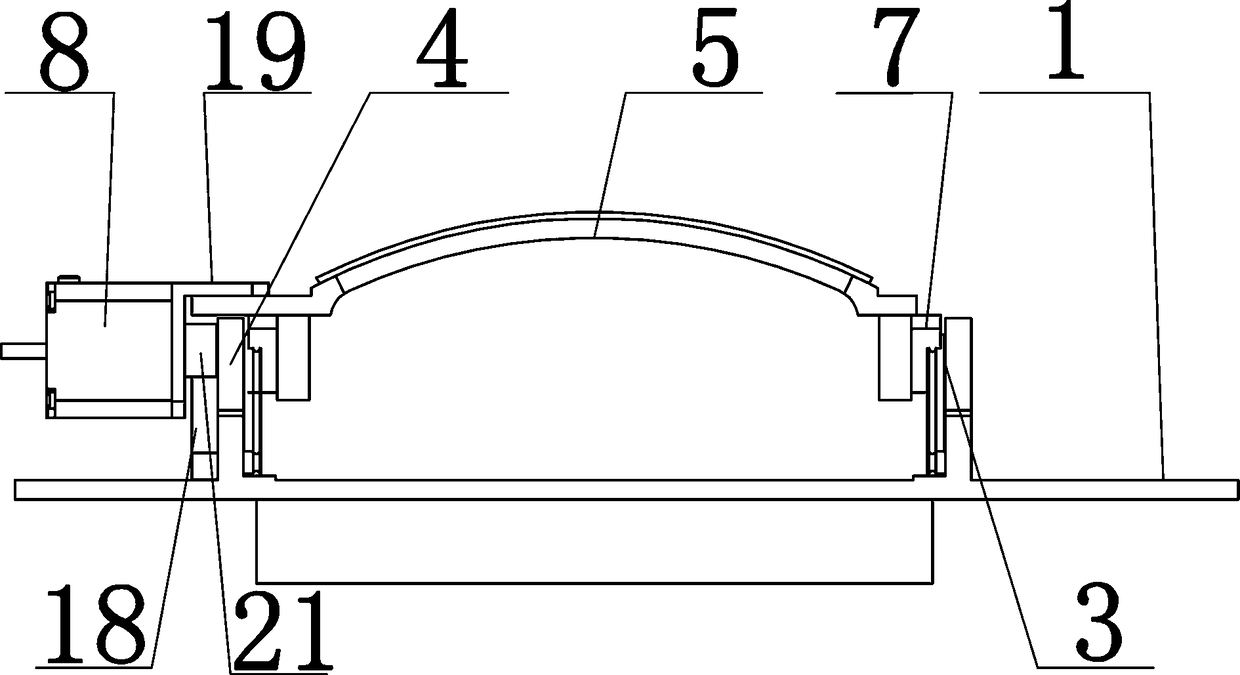

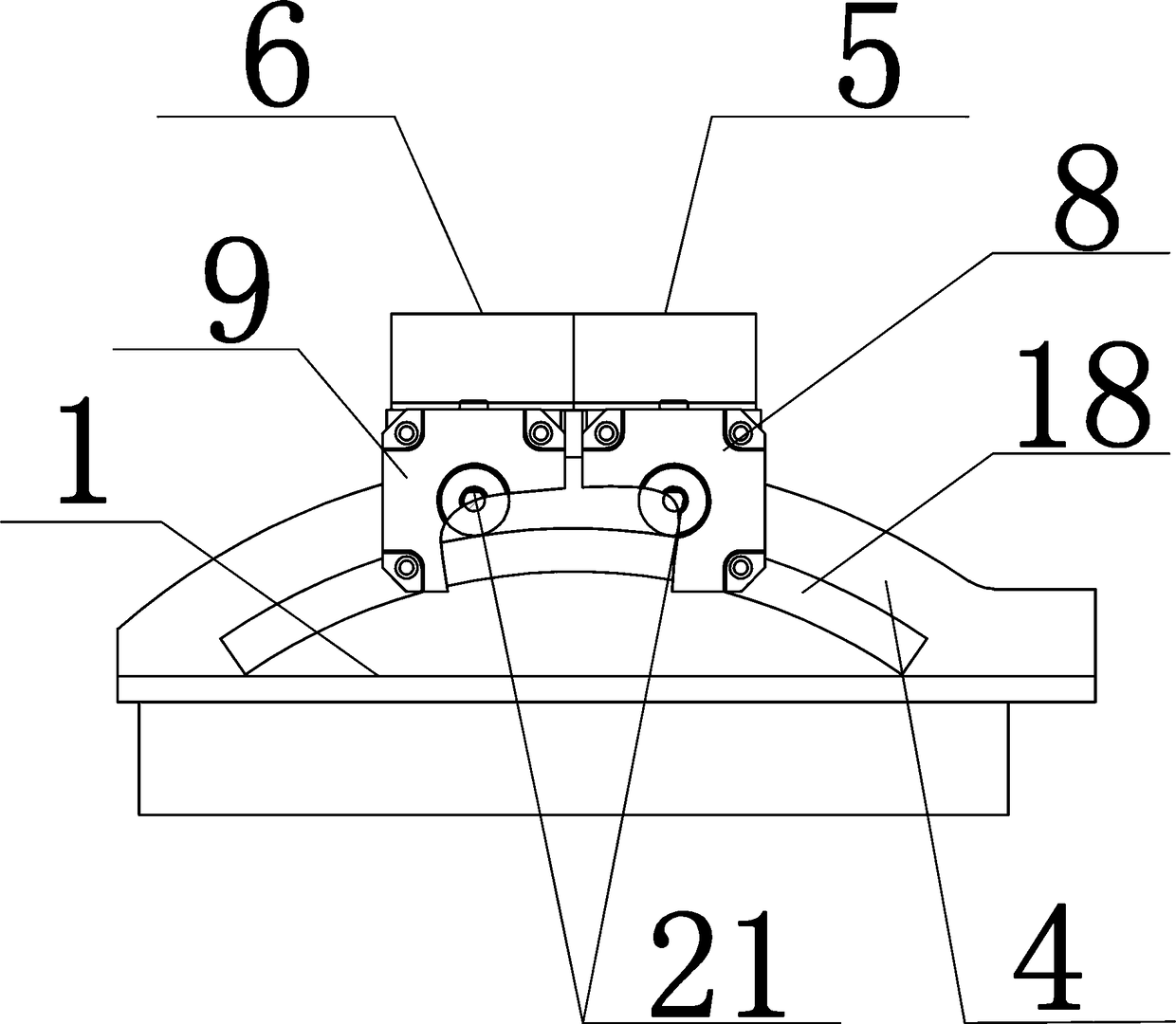

[0040] The transmission mechanism includes an arc rack 18 arranged on the side of the first arc guide rail 3 facing away from the through hole 2, and the arc rack 18 has the same radian as that of the first arc guide rail 3; The left ends of the optical shutter plate 5 and the second optical shutter plate 6 are respectively connected with a first transition plate 19 and a second transition plate 20, and the sides of the first transition plate 19 and the second transition plate 20 are respectively provided with a first motor 8 and the second motor 9, the output shafts of the first motor 8 and the second motor 9 are respectively sleeved with gears 21, and the first motor 8 and the second motor 9 connect with the arc-shaped teeth through the gears 21 and Bar 18 engages.

[0041] The first transition plate 19 and the second transition plate 20 are symmetrically arranged inverted L-shaped bent plates, and the two inverted L-shaped bent plates are arranged opposite to each other at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com