Load module cover opening structure

A load module and cover structure technology, applied in the field of load module cover opening structure, can solve the problems of lifting force, time-consuming and labor-intensive opening of the upper cover plate, and achieve simple and practical load module cover opening structure, stable mechanism movement, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described in detail, but invention protection content is not limited to described embodiment:

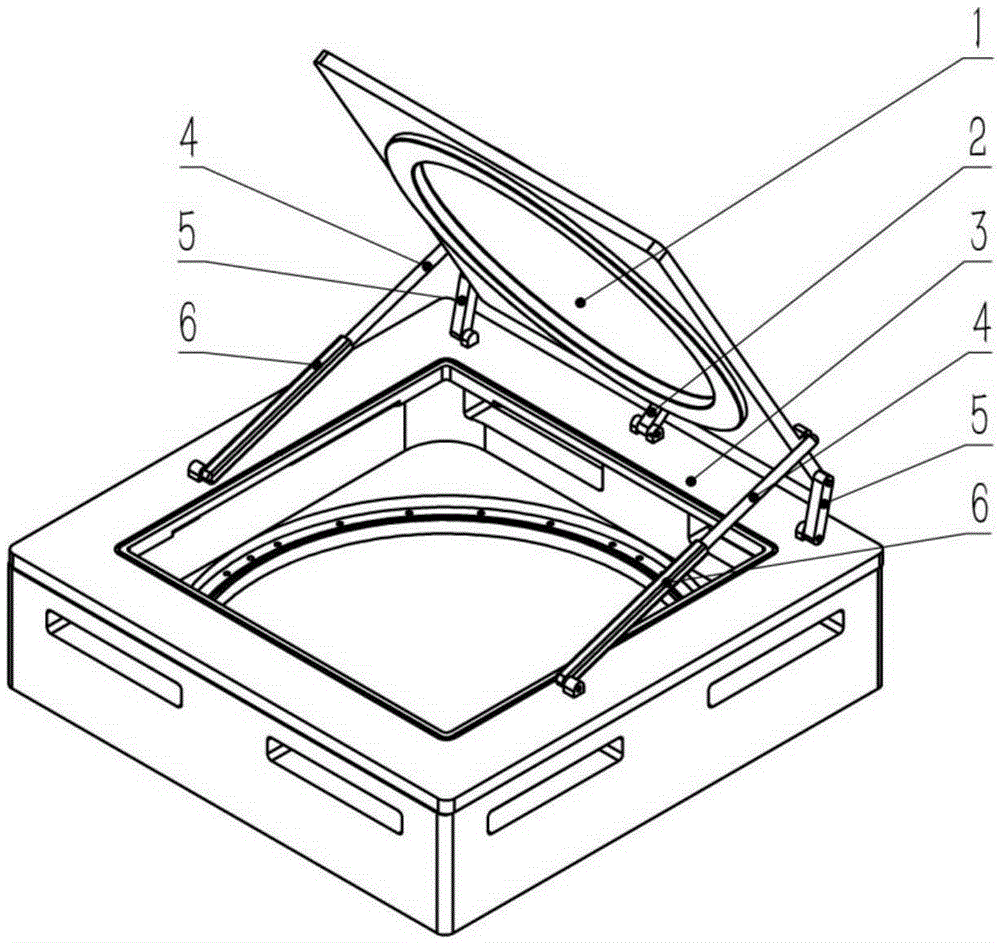

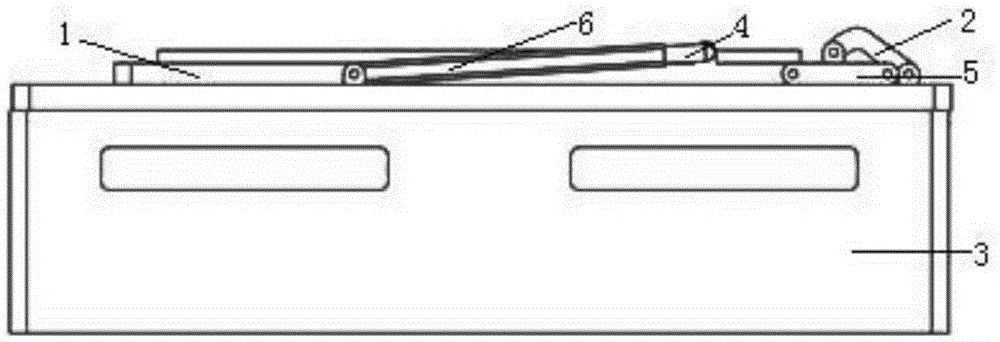

[0014] refer to Figure 1-2 , a load module cover opening structure, the cover opening structure includes a cover plate 1, a curved connecting rod 2, a load cavity 3, a cylinder 4, a straight connecting rod 5 and a cylinder liner 6; the cover plate 1 and the load cavity The body 3 is connected with the straight connecting rod 5 through the curved connecting rod 2, and the two cylinder liners 6 are respectively fixedly installed on both sides of the upper surface of the load cavity 3, and the two sides of the upper cover plate 1 are respectively fixed with the cylinder 4, The cylinder 4 is inserted into the cylinder liner 6 and connected flexibly.

[0015] There are two straight connecting rods 5 .

[0016] The cylinder 4 is telescopic in the cylinder liner 6 .

[0017] When closed, each structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com