Production technology of resinified waterproof joint filling material

A joint filling material and production process technology, applied in building insulation materials, building components, construction, etc., can solve the problems of pungent odor, phenol volatilization, troublesome construction, etc., and achieve improved elasticity and softening point, less volatilization, and lower Crisp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention are described below to facilitate the understanding of those skilled in the art.

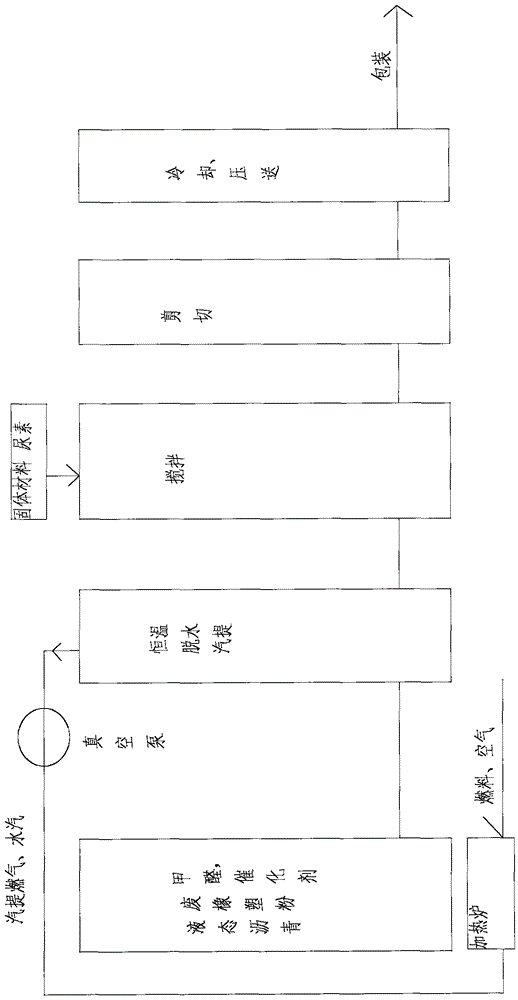

[0016] Such as figure 1 Said, the present invention provides a kind of production technology of resinized waterproof caulking material, comprises the following steps:

[0017] (1) add catalyst and formaldehyde after asphalt, waste plastics, waste rubber are mixed, and stir;

[0018] (2) Heating to 160-170°C through a heating furnace, and carrying out negative 2PA stripping through a vacuum pump at the same time;

[0019] (3) After adding solid material, urea, and directional solidification inhibitor to solidify, stir again, during which the solidification time is 2-3 hours;

[0020] (4) shearing by a shearing machine, shearing into a three-dimensional network structure, then cooling and escorting;

[0021] (5) Finally package the finished product.

[0022] Working principle: Phenol in asphalt can react with environmentally friendly form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com