Naproxen and esomeprazole magnesium compound enteric coated tablets and preparation method thereof

A technology for esomeprazole magnesium and naproxen intestines is applied in the directions of pharmaceutical formulations, medical preparations containing active ingredients, organic active ingredients, etc. The preparation process is easy and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1: Naproxen Esomeprazole Magnesium Enteric-Coated Tablets

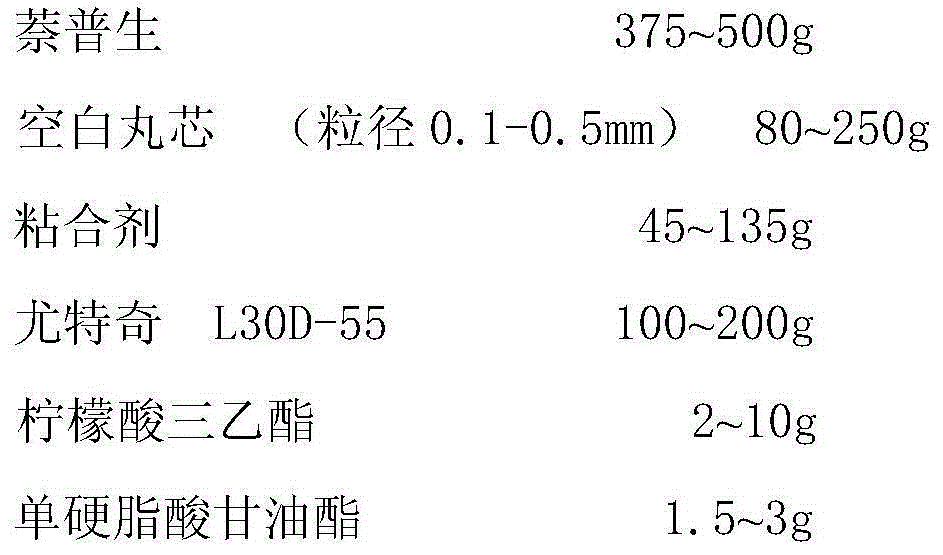

[0067]

[0068]

[0069] Preparation:

[0070] (1) Dissolve 650g of hypromellose (E5) in 13,600g of purified water, slowly add 3,750g of naproxen raw material (D90<10 microns) micronized by jet mill (model H100) under stirring, and continue stirring to prepare drug suspension;

[0071] (2) Take 900g of microcrystalline cellulose pellet core (0.1-0.2mm) and place it in a fluidized bed (model FLZB-10), preheat until the product temperature is 35°C±2°C, spray into step (1) to apply the drug Suspension, adjust fluidized bed inlet air temperature (45-55°C), inlet air volume (300-800m 3 / h), spray speed (5-100g / min) and atomization pressure (1-3bar), so that the product temperature is 35±2°C, and the pellets are in a fluidized state, no adhesion, no spray drying, until After spraying the drug suspension, keep the product temperature and continue to dry for 30 minutes, so that the water content of the...

Embodiment 2

[0085] Example 2: Naproxen Esomeprazole Magnesium Enteric-Coated Tablets

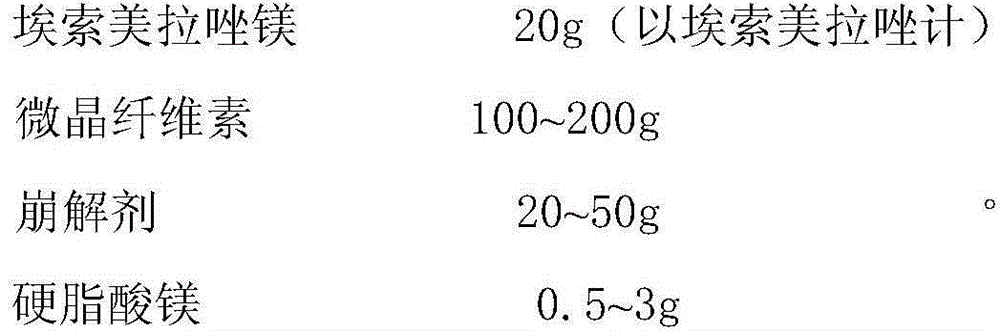

[0086]

[0087]

[0088] Preparation:

[0089] (1) Dissolve 866.7 g of hypromellose (E5) in 18,133 g of purified water, slowly add 5,000 g of naproxen raw material (D90<10 microns) micronized by a jet mill (model H100) under stirring, and continue stirring to prepare into a drug suspension;

[0090] (2) Take 1200g of microcrystalline cellulose pellet core (0.1-0.2mm) and place it in a fluidized bed, preheat until the product temperature is 45°C±2°C, spray the drug suspension in step (1), and adjust the fluidization Bed inlet air temperature (55-65℃), inlet air volume (300-900m3 / h), liquid spray speed (5-100g / min) and atomization pressure (1-3bar), so that the product temperature is 45±2℃ , and make the pellets in a fluidized state, non-adhesive, not spray-dried, until the drug suspension is sprayed, maintain the product temperature, and continue to dry for 10 minutes, so that the moisture conten...

Embodiment 3

[0104] Example 3: Naproxen and Esomeprazole Magnesium Compound Enteric-coated Tablets

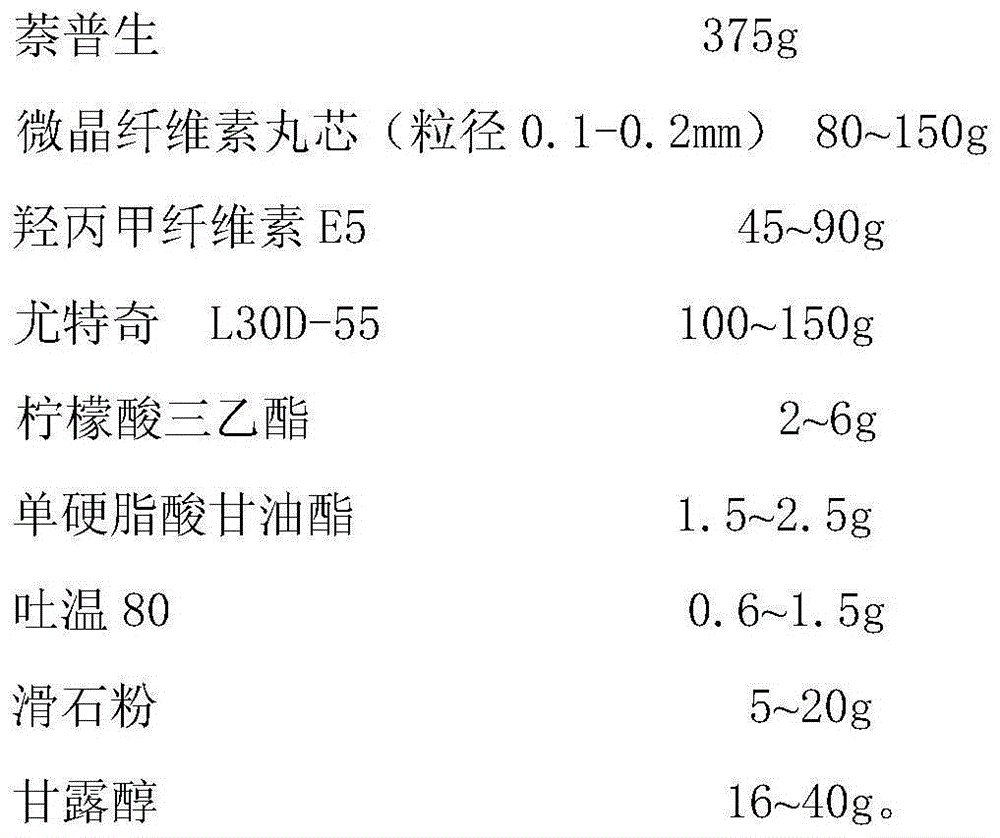

[0105]

[0106] Preparation:

[0107] (1) Dissolve 650g of hypromellose (E5) in 13,600g of purified water, slowly add 3,750g of naproxen raw material (D90<10 microns) micronized by jet mill (model H100) under stirring, and continue stirring to prepare drug suspension;

[0108] (2) Take 900g of microcrystalline cellulose pellet core (0.1-0.2mm) and place it in a fluidized bed, preheat it until the product temperature is 35-45°C, spray the drug suspension in step (1), and adjust the fluidized bed Inlet air temperature (45-55°C), air intake volume (300-900m 3 / h), spray speed (5-100g / min) and atomization pressure (1-3bar), so that the product temperature is 35-45°C, and the pellets are in a fluidized state, no adhesion, no spray drying, until After the drug suspension is sprayed, continue to dry for 30 minutes, so that the water content of the pellets is <1.5%, and the drug-containing pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| release amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com