Preparation method of ternary positive electrode material for lithium ion battery

A technology for lithium-ion batteries and cathode materials, which is applied in battery electrodes, electrical components, secondary batteries, etc., can solve problems such as poor particle conductivity, damage to battery performance, and porosity, so as to improve electronic conductivity and lithium ion Diffusion rate, improve electrical properties and structural stability, reduce the effect of particle breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of lithium ion battery ternary cathode material of the present invention, comprises the following steps:

[0026] 1) Prepare layered ternary precursor by co-precipitation method: add 2.0mol / L nickel-cobalt-manganese sulfate solution (the molar ratio of nickel, cobalt, and manganese elements is 6:2:2) into the reactor, and then add NaOH solution (mass fraction 20%), ammonia water (mass fraction 20%), control the pH value at about 11.5, heat to 55°C, react for 10h, filter, wash, and dry to obtain (Ni 0.6 co 0.2 mn 0.2 )(OH) 2 ;

[0027] 2) Get 500g of (Ni 0.6 co 0.2 mn 0.2 )(OH) 2 Disperse in 2.0L formamide and stir at 500rpm for 12h to generate a positively charged layered precursor dispersion;

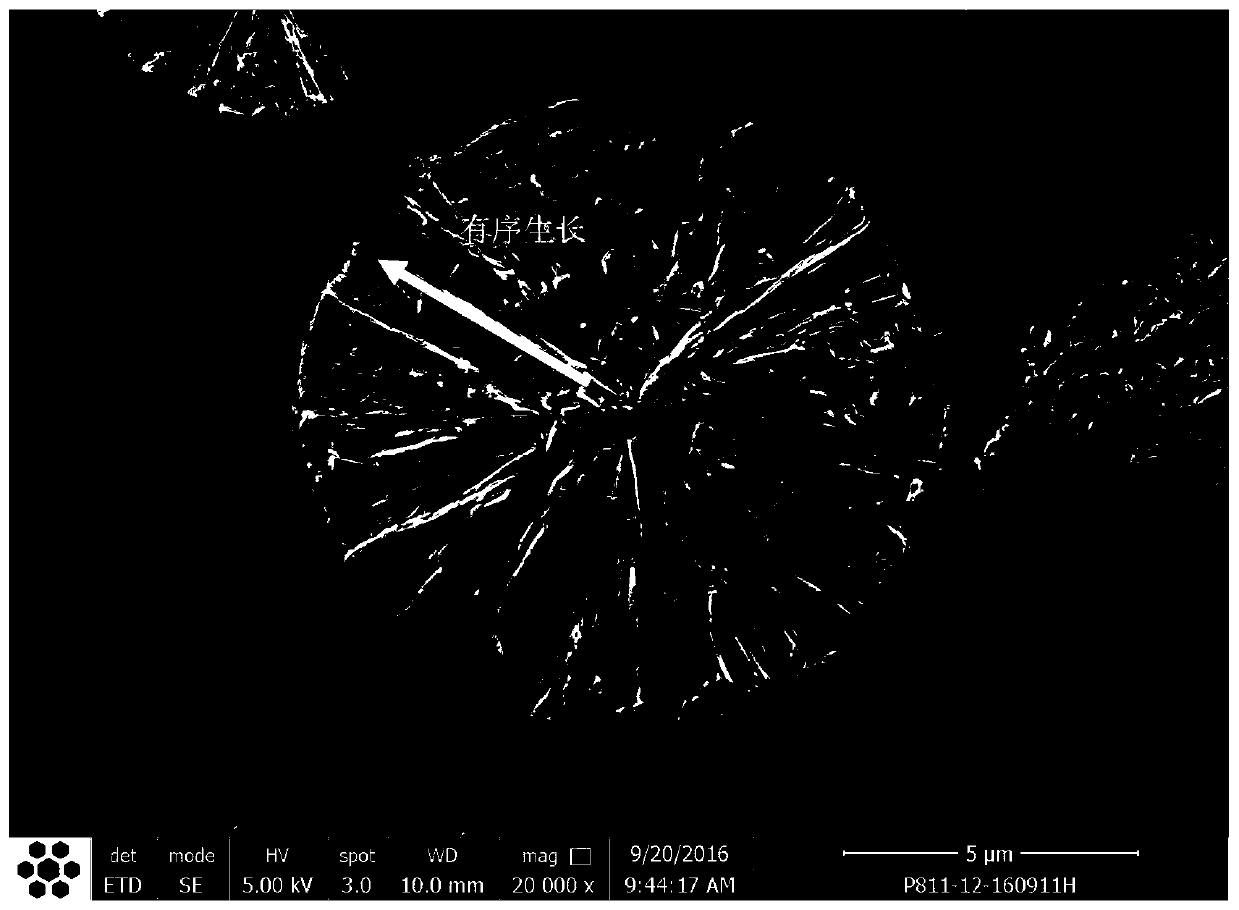

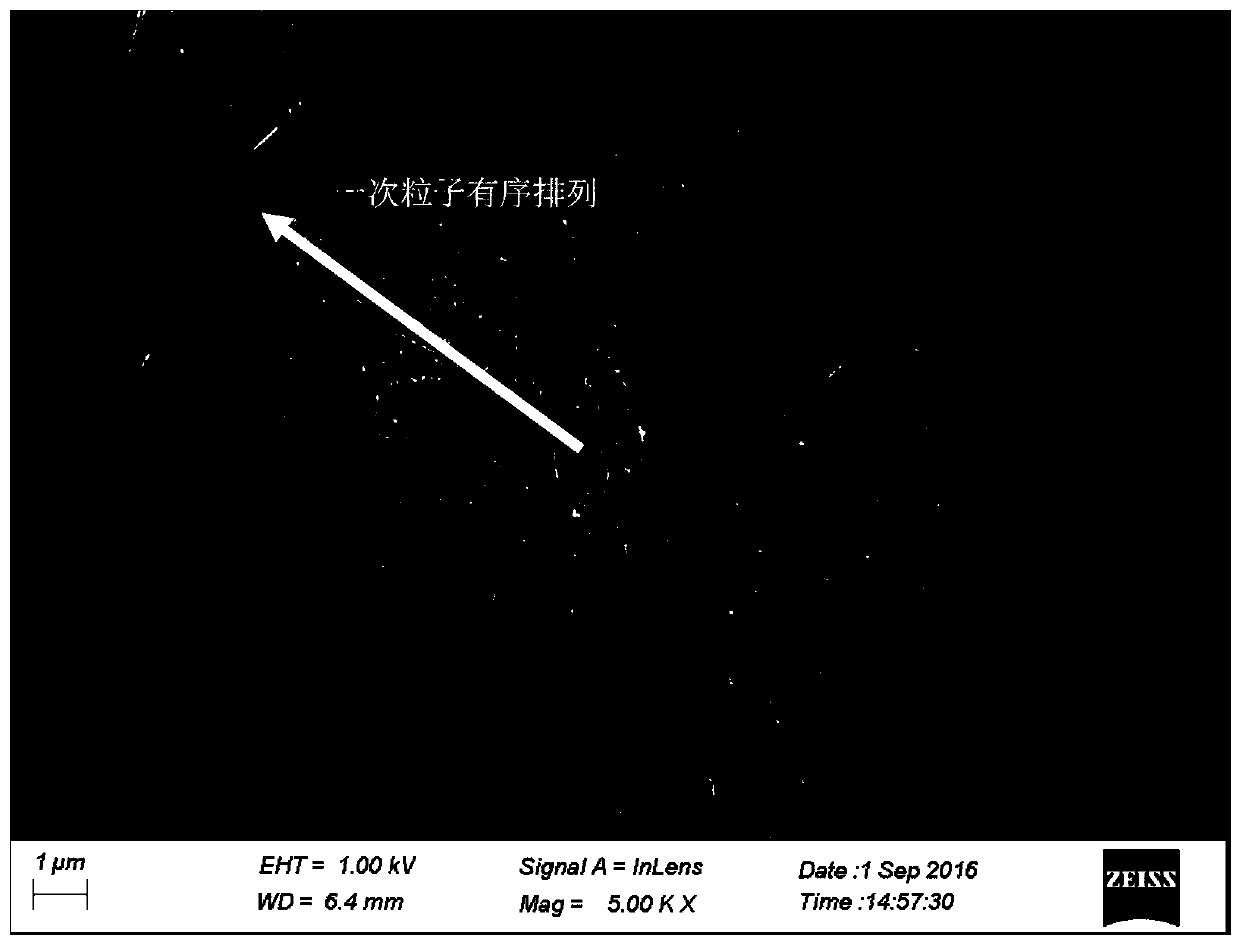

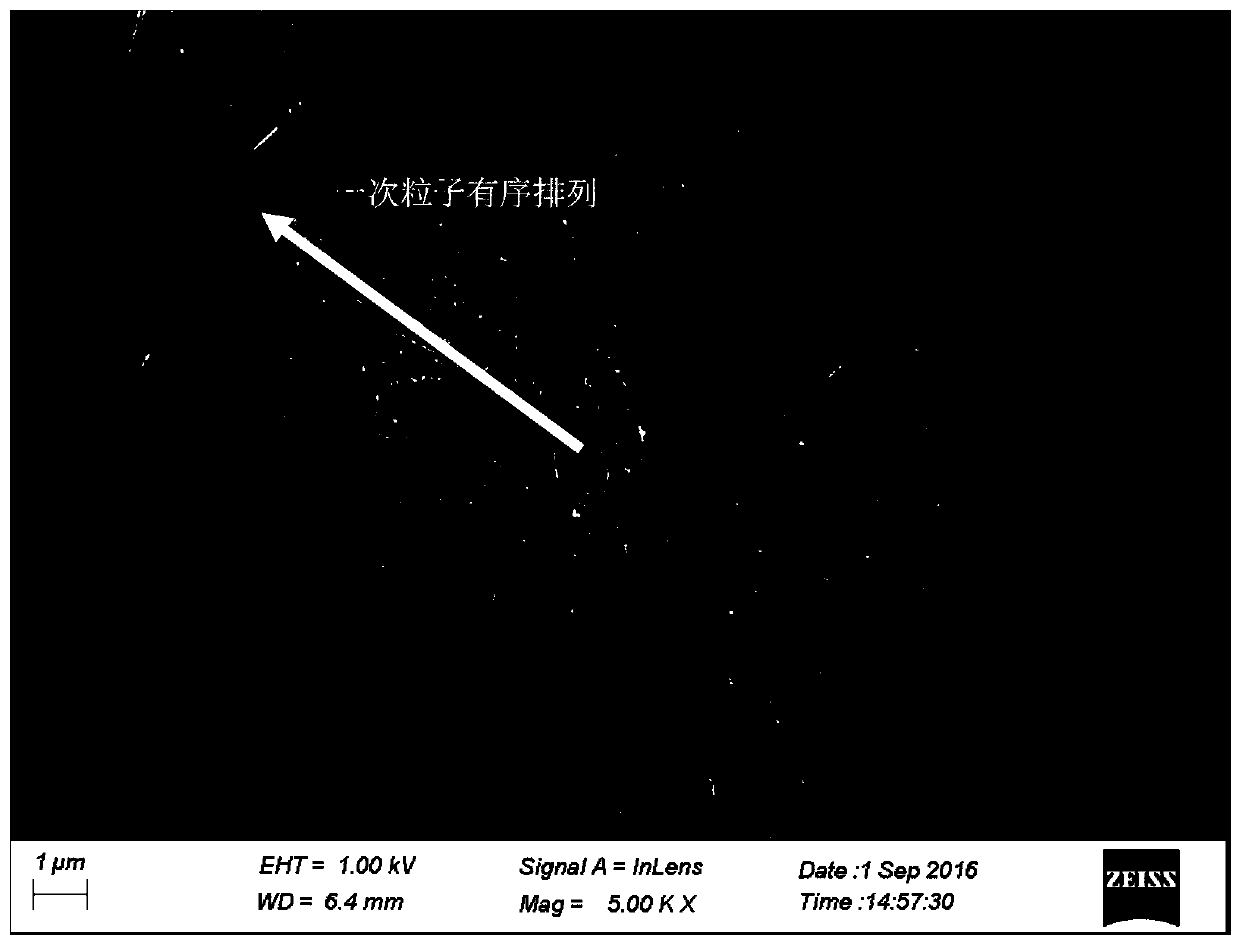

[0028] 3) under the condition of constant stirring, add 250mL negatively charged graphene oxide solution (1.0mg / mL) to step 2) in the layered precursor dispersion that obtains, the consumption of layered compound in the graphene oxide solution is 0....

Embodiment 2

[0037] A preparation method of lithium ion battery ternary cathode material of the present invention, comprises the following steps:

[0038] 1) Prepare layered ternary precursor by co-precipitation method: add 2.0mol / L nickel-cobalt-manganese sulfate solution (the molar ratio of nickel, cobalt, and manganese elements is 1:1:1) into the reactor, and then add NaOH solution (mass fraction 25%), ammonia water (mass fraction 20%), control the pH value at 11.0, heat to 55°C, react for 10h, filter, wash, and dry to obtain (Ni 1 / 3 co 1 / 3 mn 1 / 3 )(OH) 2 ;

[0039] 2) Get 500g of (Ni 1 / 3 co 1 / 3 mn 1 / 3 )(OH) 2 Disperse in 2.0L isopropanol and stir at 500rpm for 12h to generate a positively charged layered precursor dispersion;

[0040] 3) Under the condition of constant stirring, add 250mL containing 1.5gAl(NO 3 ) 3 Negatively charged graphene oxide solution (1.0mg / mL), the amount of layered compound in the graphene oxide solution is 3.5% of the total mass of the layered precurs...

Embodiment 3

[0047] A preparation method of lithium ion battery ternary cathode material of the present invention, comprises the following steps:

[0048] 1) Prepare layered ternary precursor by co-precipitation method: add 2.0mol / L nickel-cobalt-manganese sulfate solution (the molar ratio of nickel, cobalt, and manganese elements is 8:1:1) into the reactor, and then add NaOH solution (mass fraction 25%), ammonia water (mass fraction 20%), control the pH value at 12.0, heat to 55°C, react for 10h, filter, wash, and dry to obtain (Ni 0.8 co 0.1 mn 0.1 )(OH) 2 ;

[0049] 2) Get 500g of (Ni 0.8 co 0.1 mn 0.1 )(OH) 2 Disperse in 2.0L N-N-dimethylformamide, stir at 500rpm for 12h to generate a positively charged layered precursor dispersion;

[0050] 3) Under the condition of constant stirring, add 250mL containing 1.8gMg(NO 3 ) 2 Negatively charged graphene oxide solution (1.0mg / mL), the amount of layered compound in the graphene oxide solution was 4.1% of the total mass of the layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com