High-temperature resistant turns bowl

A technology with high temperature resistance and main body, which is applied in the manufacture of magnetic cores, electrical components, inductors/transformers/magnets, etc., can solve the problems of easy deformation and distortion of magnetic cores, uneven bottom surface, high scrap rate, etc., to avoid deformation of magnetic cores, The effect of reducing scrap rate and improving high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

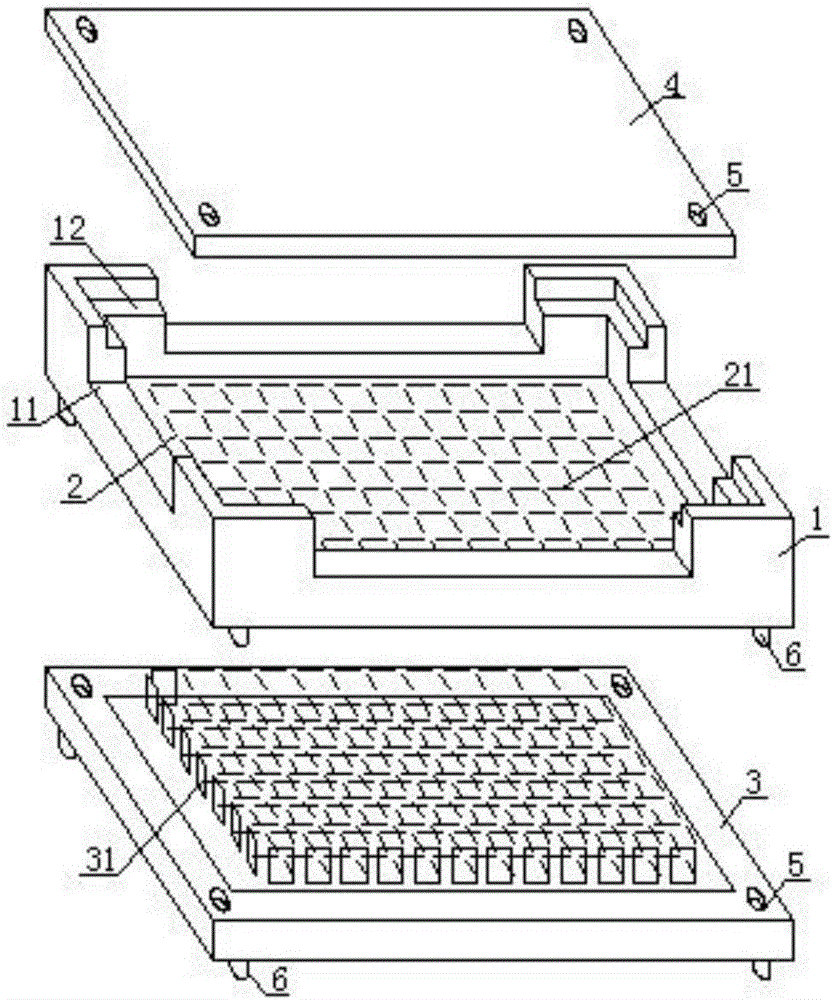

[0026] A high-temperature-resistant bowl, comprising a main body 1 of the bowl; the main body 1 of the bowl is provided with a setter plate 2, the surface of the setter plate 2 is coated with zirconia, the thickness of the zirconia is 0.05mm-1mm, and the setter plate 2 There are a number of limiting slots 21 on the top, and a limiting plate 3 is arranged under the main body 1 of the turn bowl. The limiting plate 3 is provided with a number of limiting pieces 31 for limiting the movement or deformation of the magnetic core during sintering. The bit groove 21 passes through and extends out of the upper surface of the setter 2 .

[0027] The surface of the setter 2 of the present invention is coated with zirconia, the setter surface is smooth, and the magnetic core does not produce concave and convex points during sintering. Zirconia dissipates heat evenly, which can make the magnetic core product evenly heated and avoid the deformation of the product due to uneven heating. By p...

Embodiment 2

[0030] A high temperature resistant bowl, comprising a main body 1 of the bowl; the main body 1 of the bowl is provided with a setter plate 2, the surface of the setter plate 2 is coated with zirconia, the thickness of the zirconia is 0.05mm, and the setter plate 2 is provided with There are a number of limiting slots 21, a limiting plate 3 is arranged under the main body 1 of the turn bowl, and a number of limiting plates 31 are arranged on the limiting plate 3 to limit the movement or deformation of the magnetic core during sintering. 21 passes through and stretches out the upper surface of setter 2.

[0031] The surface of the setter 2 of the present invention is coated with zirconia, the setter surface is smooth, and the magnetic core does not produce concave and convex points during sintering. Zirconia dissipates heat evenly, which can make the magnetic core product evenly heated and avoid the deformation of the product due to uneven heating. By passing the limiting piec...

Embodiment 3

[0035] A high-temperature-resistant bowl, comprising a main body 1 of the bowl; the main body 1 of the bowl is provided with a setter plate 2, the surface of the setter plate 2 is coated with zirconia, the thickness of the zirconia is 1mm, and the setter plate 2 is provided with A plurality of limiting grooves 21, a limiting plate 3 is arranged under the main body 1 of the turn bowl, and a plurality of limiting plates 31 are arranged on the limiting plate 3 for limiting movement or deformation of the magnetic core during sintering, and the limiting plates 31 are separated from the limiting groove 21 Pass through and stretch out the upper surface of setter 2.

[0036] The surface of the setter 2 of the present invention is coated with zirconia, the setter surface is smooth, and the magnetic core does not produce concave and convex points during sintering. Zirconia dissipates heat evenly, which can make the magnetic core product evenly heated and avoid the deformation of the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com