Accurate qualitative and quantitative detection method for oil adjuvant vaccine

A quantitative detection method and oil adjuvant technology, which are used in measurement devices, preparation and sampling of samples for testing, etc., can solve problems such as intractability and inability to detect water phase after demulsification, so as to improve accuracy and increase equipment maintenance. And the cost of use, the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides an accurate qualitative and quantitative detection method for oil adjuvant vaccines, comprising the following steps:

[0049] 1) vaccine to be tested (commercially available porcine foot-and-mouth disease vaccine, concentration is 75ug / ml) is mixed with demulsifier, organic solvent is selected acetonitrile for use in described demulsifier, acid is selected trifluoroacetic acid for use, and the volume ratio of acetonitrile and trifluoroacetic acid is 100:0.05. Take 8ml of the vaccine to be tested and put it in a centrifuge tube. Mix the vaccine and demulsifier at a volume ratio of 8:2, shake and mix well, and centrifuge at 3000G for 15 minutes at 4°C. After centrifugation, carefully extract the lower aqueous phase with a 10ml syringe.

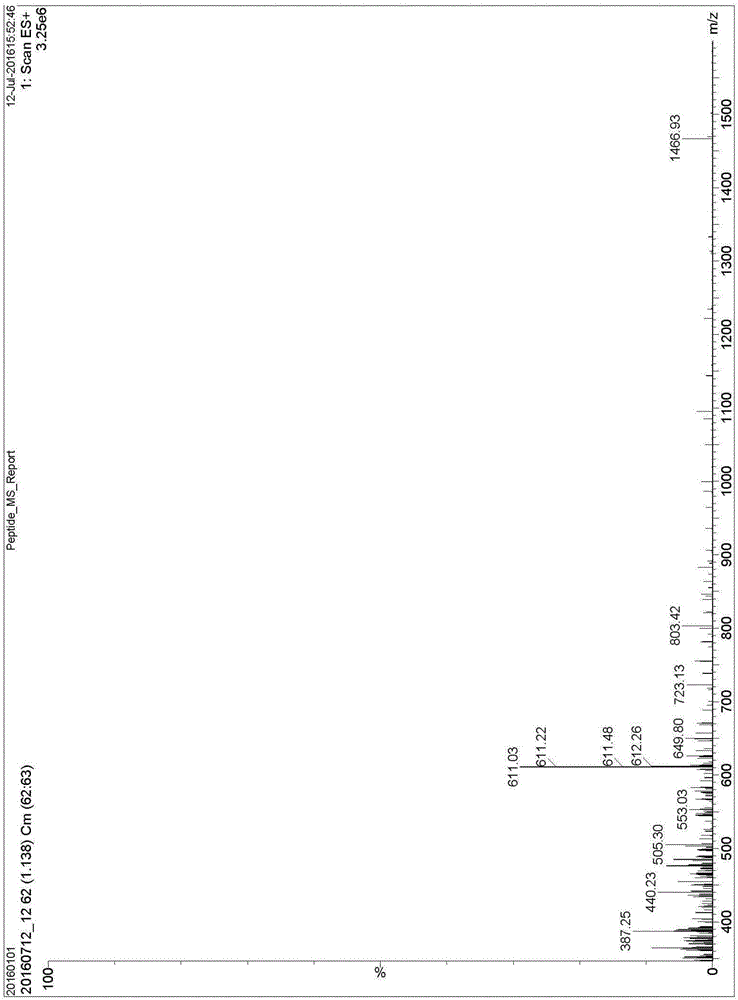

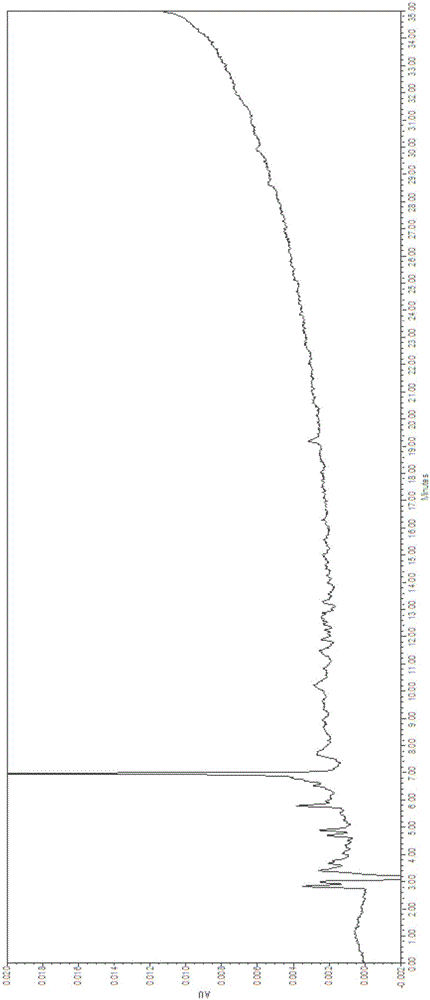

[0050] 2) Take 0.1ml of the aqueous phase antigen sample prepared in step 1, and use HPLC to detect that the concentration of the sample is 68.8ug / ml, and the demulsification efficiency is 91.7%.

[0051] 3) Prec...

Embodiment 2

[0064] This embodiment provides an accurate qualitative and quantitative detection method for oil adjuvant vaccines, comprising the following steps:

[0065] 1) select commercially available porcine foot-and-mouth disease vaccine vaccine (vaccine concentration is 75ug / ml) and handle according to following method demulsification: vaccine to be tested is mixed with demulsifier, organic solvent is selected acetonitrile for use in described demulsifier, acid selects trifluoroacetic acid for use, The volume ratio of acetonitrile to trifluoroacetic acid is 100:0.05. Take 5ml of the vaccine to be tested and mix it with the demulsifier at a volume ratio of 5:5, shake and mix well, and centrifuge at 3000G for 15 minutes at 4°C to obtain the aqueous phase antigen sample.

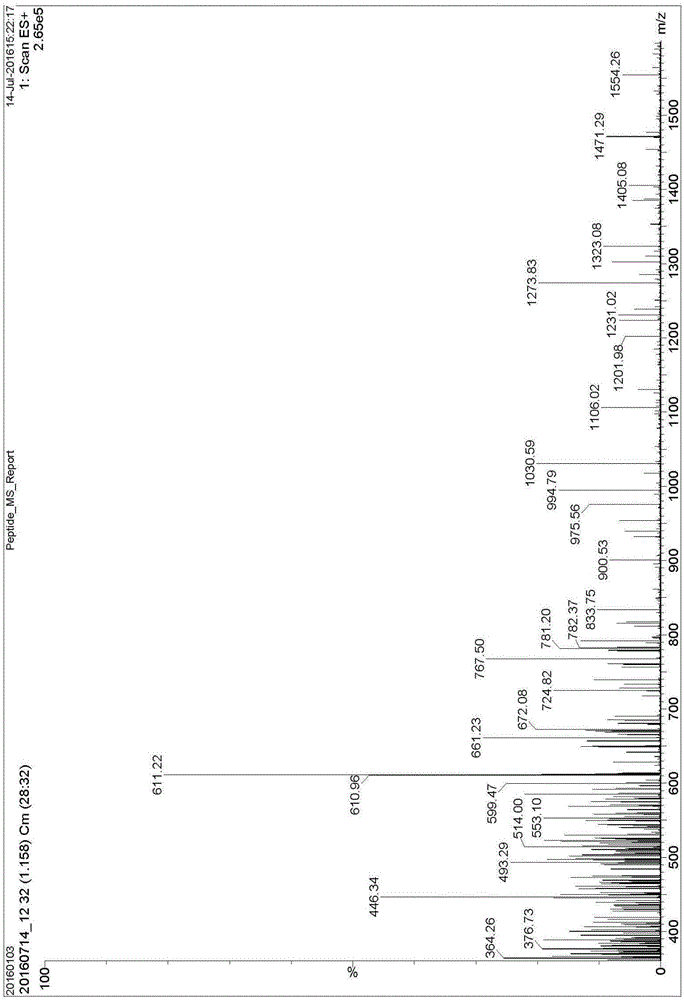

[0066] 2) Take 0.1ml of the aqueous phase antigen sample prepared in step 1, and use HPLC to detect that the concentration of the sample is 67.7ug / ml, and the antigen recovery rate obtained by using this method is 90....

Embodiment 3

[0080] This embodiment provides a precise qualitative and quantitative detection method for oil adjuvant vaccines, comprising the following steps:

[0081] 1) select the commercially available porcine foot-and-mouth disease vaccine (vaccine concentration is 75ug / ml) to handle demulsification according to the following method: the vaccine to be tested is mixed with the demulsifier, and the organic solvent is selected ethanol in the described demulsifier, and the acid is selected hydrochloric acid for use, ethanol and demulsifier The volume ratio of hydrochloric acid is 100:0.33. Take 7ml of the vaccine to be tested and mix it with the demulsifier at a volume ratio of 7:3, shake and mix, and centrifuge at 3000G for 15 minutes at 4°C to obtain an aqueous phase antigen sample.

[0082] 2) Take 0.1ml of the aqueous phase antigen sample prepared in step 1, and use HPLC to detect the concentration of the sample is 70.1ug / ml, and the antigen recovery rate obtained by using this method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com