Demulsifier composition and lubricating oil

A technology of demulsifier and composition, applied in the field of demulsifier composition, can solve the problems of changes in anti-emulsification properties, inability to realize various demulsifier properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

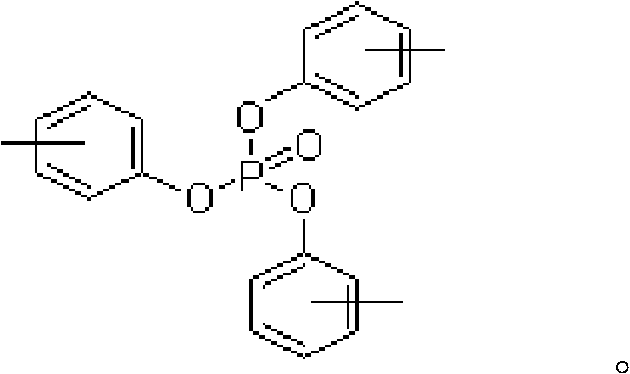

example 1

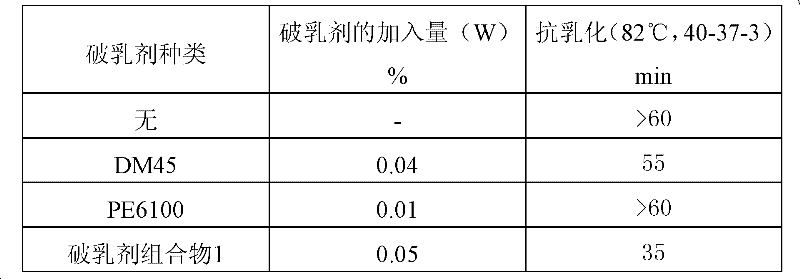

[0024] Mix tricresyl phosphate type demulsifier and polyether type demulsifier 1 according to the mass ratio of 80:20, and stir them evenly by mechanical or manual at 20°C-50°C to prepare demulsifier composition 1, wherein The main component of the tricresyl phosphate demulsifier is tricresyl phosphate (DM45), and the main component of the polyether demulsifier is a block polymer of polyethylene oxide and polypropylene oxide (PE6100). The obtained demulsifier composition 1 was added to the worm gear lubricating oil according to the amount of 0.05%, and the anti-emulsification performance of the oil product of the lubricating oil was measured. The emulsion and the worm gear lubricating oil added with polyether demulsifier were tested, and the test results are shown in Table 2.

[0025] Table 2 Anti-emulsification performance of worm gear lubricating oil

[0026]

[0027] As can be seen from Table 2, no demulsifier is added to the worm gear lubricating oil, tricresyl phospha...

example 2

[0029] Mix tricresyl phosphate type demulsifier and polyether type demulsifier 2 according to the ratio of 50:50, and stir them evenly by mechanical or manual at the temperature of 20°C-50°C to prepare demulsifier composition 2, in which tricresyl phosphate The main component of the cresyl ester demulsifier is tricresyl phosphate (DM45), and the main component of the polyether demulsifier is the block polymer of polyethylene oxide and polypropylene oxide (LZ5957). The obtained demulsifier composition 2 was added to the worm gear lubricating oil according to the amount of 0.02%, and the anti-emulsification performance of the oil product of the lubricating oil was measured. The emulsion and the worm gear lubricating oil added with polyether demulsifier were tested, and the test results are shown in Table 3.

[0030] Table 3. Anti-emulsification performance of worm gear lubricating oil

[0031]

[0032]

[0033] It can be seen from Table 3 that in the worm gear lubricating...

example 3

[0035] Mix the tricresyl phosphate demulsifier and the polyether demulsifier 3 in a ratio of 60:40, and stir them uniformly by mechanical or manual at a temperature of 20°C-50°C to form a demulsifier composition 3, in which tricresyl phosphate The main component of the cresyl ester demulsifier is tricresyl phosphate (DM45), and the main component of the polyether demulsifier 3 is a block polymer of polyethylene oxide and polypropylene oxide (DL32). The obtained demulsifier composition 3 was added to the worm gear lubricating oil according to the amount of 0.05%, and the anti-emulsification performance of the oil product of the lubricating oil was measured. The emulsion and the worm gear lubricating oil added with polyether demulsifier were tested, and the test results are shown in Table 4.

[0036] Table 4. Anti-emulsification properties of worm gear lubricants

[0037]

[0038] It can be seen from Table 4 that in the worm gear lubricating oil without adding demulsifier, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com