Organic silicon glove leather and preparation method thereof

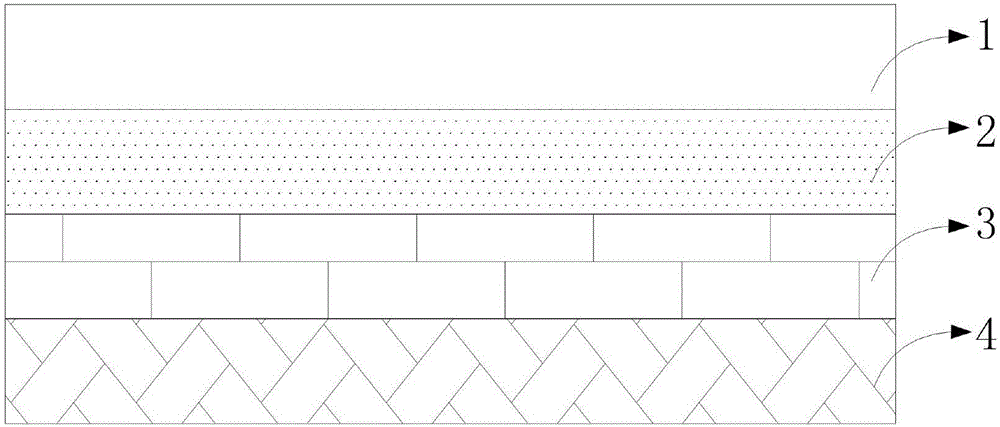

A technology of glove leather and silicone, applied in gloves, clothing, applications, etc., can solve the problems of easy aging, limited anti-skid performance of PU leather surface, and does not meet the requirements of environmental protection and health, and achieve strong three-dimensional effect and clear pattern layers , soft touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Based on the components contained in the above-mentioned non-slip surface adhesive layer and the mass ratio of each component, the preparation method of the silicone glove leather includes:

[0042] Form a monochrome silica gel layer: apply liquid silica gel on the mirror release paper or release film, vulcanize at 80°C to 150°C for 2min to 10min, and form a monochrome silica gel layer on the mirror release paper or release film;

[0043] Bonding base cloth: apply liquid silicone on the monochrome silica gel layer, attach the base cloth on the liquid silica gel, and vulcanize at 80℃~150℃ for 5min~20min to form a monochrome skin;

[0044] Cutting monochrome leather: peel off the mirror release paper or release film, and cut the prepared monochrome leather according to the specifications;

[0045] Equipped with non-slip surface rubber layer:

[0046] 100 parts of P40 base rubber, 30-50 parts of 500-1000mpa.s terminal vinyl silicone oil, 0.1-1 part of platinum catalyst, 0...

Embodiment 1

[0053] In the preparation method of silicone glove leather, in the step of forming a monochromatic silica gel layer, the liquid silica gel coated on the mirror release paper is 40-degree addition type liquid silica gel P40 produced by Huizhou Huacheng New Material Co., Ltd., and the liquid silica gel is added 10% white paste; in the silk screen pattern layer step, the liquid silicone that is screen printed on the cut single-color leather is 40-degree addition type liquid silicone P40 produced by Huizhou Huacheng New Material Co., Ltd., wherein, in the silk screen pattern layer step, formed Add 25% black paste to the liquid silica gel used in the pattern layer; in the step of attaching the base cloth, the selected base cloth is 0.5mm thick polyester cloth. The preparation method of silicone glove leather in the present embodiment is as follows:

[0054] Form a monochrome silica gel layer: apply liquid silica gel with 10% white paste on the mirror release paper, control the coat...

Embodiment 2

[0061] In the preparation method of silicone glove leather, in the step of forming a monochromatic silica gel layer, the liquid silica gel coated on the mirror release paper is 40-degree addition type liquid silica gel P40 produced by Huizhou Huacheng New Material Co., Ltd., and the liquid silica gel is added 10% white paste; in the step of silk screen pattern layer, the liquid silicone that is screen printed onto the cut single-color leather is 40-degree addition type liquid silicone P40 produced by Huizhou Huacheng New Material Co., Ltd., among which, in the silk screen pattern layer, the pattern is formed The first color used in the layer is to add 25% black paste to the liquid silica gel, and the second color used to form the pattern layer is to add 25% red paste to the liquid silica gel; in the step of attaching the base cloth, the selected base cloth is 0.6 mm thick polyester fabric. The preparation method of silicone glove leather in the present embodiment is as follows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com