Treatment method for bad-quality raw oil

A technology of inferior raw material oil and treatment method, which is applied in the treatment of hydrocarbon oil, hydrotreating process, petroleum industry, etc., can solve the problems of short catalyst life and high chemical hydrogen consumption, and achieve reduction of chemical hydrogen consumption, increase yield, increase The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

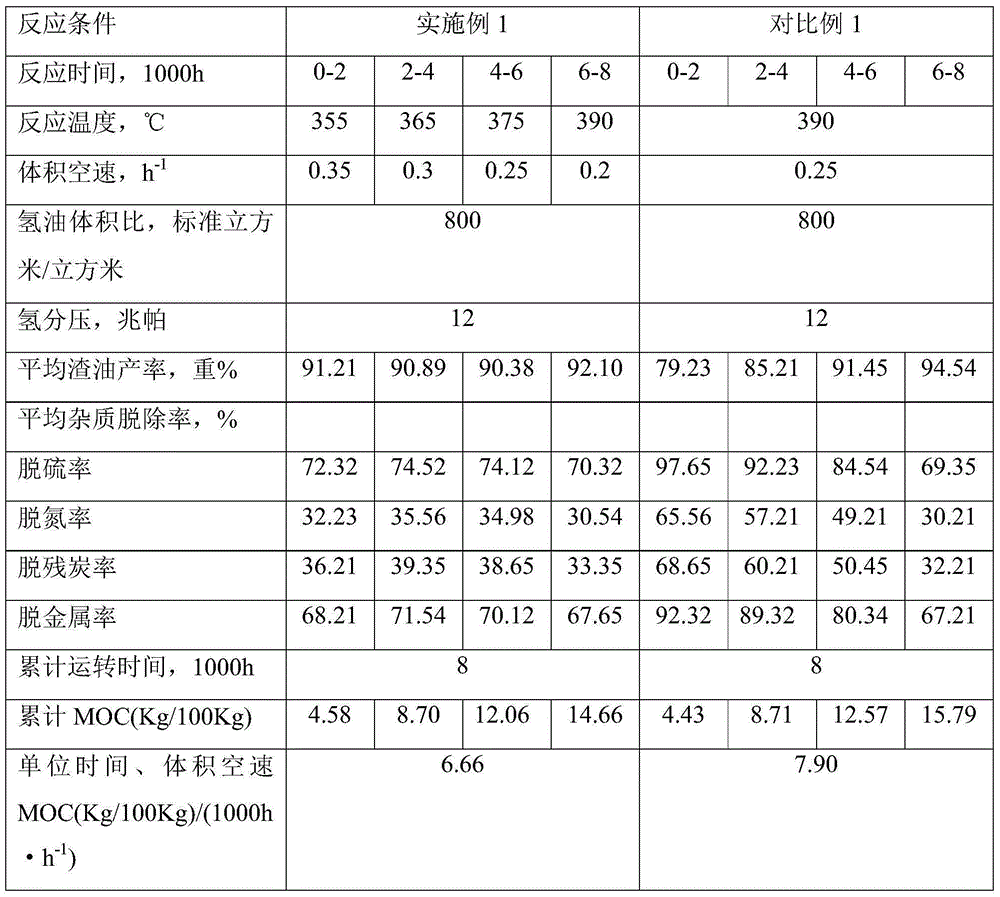

[0060] Embodiment 1 provides the controllable shallow hydrogenation reaction of the present invention, wherein the reaction temperature and volume space velocity are adjusted stepwise with the reaction time, while the hydrogen-oil volume ratio and hydrogen partial pressure are maintained at 800 standard cubic meters / cubic meter and 12 MPa, see Table 2 for specific operating conditions. Among the residue hydrogenation products, the cut point of hydrogenated residue is 350°C. The life of the residual oil hydrogenation catalyst is correlated with the amount of metal deposited on the catalyst (MOC, the amount of nickel and vanadium deposited on the catalyst per 100kg), and the MOC is inversely proportional to the catalyst life. The comparison between the impurity removal rate of the device and MOC is shown in Table 2.

Embodiment 2

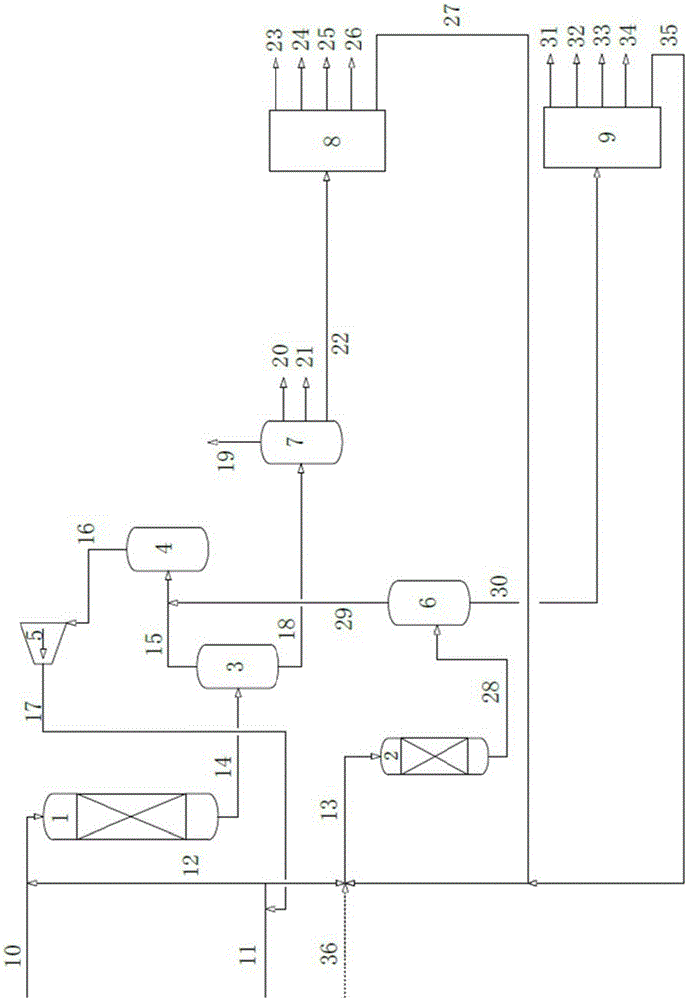

[0065] Such as figure 1 As shown, the reaction product produced within 5000-5500 hours of operation of the hydrogenation unit in Example 1 was selected as the experimental object of the subsequent process (see Table 3 for specific properties of the product after the shallow hydrogenation reaction). The hydrogenated residual oil is used as the raw material oil of the first catalytic cracking unit, and after the first catalytic cracking reaction, separation and fractionation, the first dry gas, the first liquefied gas, the first gasoline, the first diesel oil and the first wax oil are obtained. The first wax oil cut point is 330°C, accounting for 35.23% of the feed amount. The first wax oil is subjected to hydrogenation treatment of wax oil. After the product is separated from gas and liquid, the liquid-phase hydrogenated wax oil enters the second catalytic cracking reactor, and after the second catalytic cracking reaction, the second dry gas and the second liquefied gas are obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com