Gel plugging agent for plugging fluid channeling big channel of medium-temperature oil reservoir and preparation method thereof

A technology of plugging control agent and large pore channel, which is applied in the field of oil production of water injection wells, can solve problems such as poor strength and unstable system, and achieve the effects of good thermal stability, good solubility and good injection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A preparation method of a gel plugging agent for plugging channeling large pores in medium-temperature oil reservoirs, the method steps are as follows: take acrylamide, molecular chain grafting enhancer, N,N-methylene according to the above mass ratio Bisacrylamide, azobisisobutylamidine hydrochloride and water, add acrylamide, N, N-methylenebisacrylamide, azobisisobutylamidine hydrochloride in sequence, and then Add the molecular chain grafting enhancer and stir to disperse it evenly to get this product.

[0021] "Medium-temperature oil reservoir" in the name of the present invention (gel plugging agent and preparation method for blocking channeling large pores in medium-temperature oil reservoirs) refers to oil reservoirs with a temperature between 40°C and 90°C, and "large "Channel" means a channel with a diameter greater than 50 μm.

[0022] When in use, the plugging control agent of the present invention is injected into the formation or porous medium, and at mode...

Embodiment 1

[0024] Take acrylamide according to the following mass ratio: 3.0%; molecular chain grafting enhancer: 3.0%; N, N-methylenebisacrylamide: 0.03%; azobisisobutylamidine hydrochloride: 0.005%; Water, the sum of the mass percentages of each component is 100%;

[0025] Add acrylamide, N, N-methylenebisacrylamide, azobisisobutylamidine hydrochloride to water in turn, after dissolving, add molecular chain grafting enhancer and stir to disperse evenly to obtain this product . Seal the beaker containing this product and put it into an incubator, set the temperature at 70°C, and record the gelation time and gelation state. After observation, the gelled state is a rigid gel, and the gelled time is 25 hours.

Embodiment 2

[0027] Take acrylamide according to the following mass ratio: 3.5%; molecular chain grafting enhancer: 4.5%; N, N-methylenebisacrylamide: 0.1%; azobisisobutylamidine hydrochloride: 0.01%; Water, the sum of the mass percentages of each component is 100%;

[0028] Add acrylamide, N, N-methylenebisacrylamide, azobisisobutylamidine hydrochloride to water in turn, after dissolving, add molecular chain grafting enhancer and stir to disperse evenly to obtain this product . Seal the beaker containing this product and put it into an incubator, set the temperature at 70°C, and record the gelation time and gelation state. After observation, the gelled state was a rigid gel, and the gelled time was 16 hours.

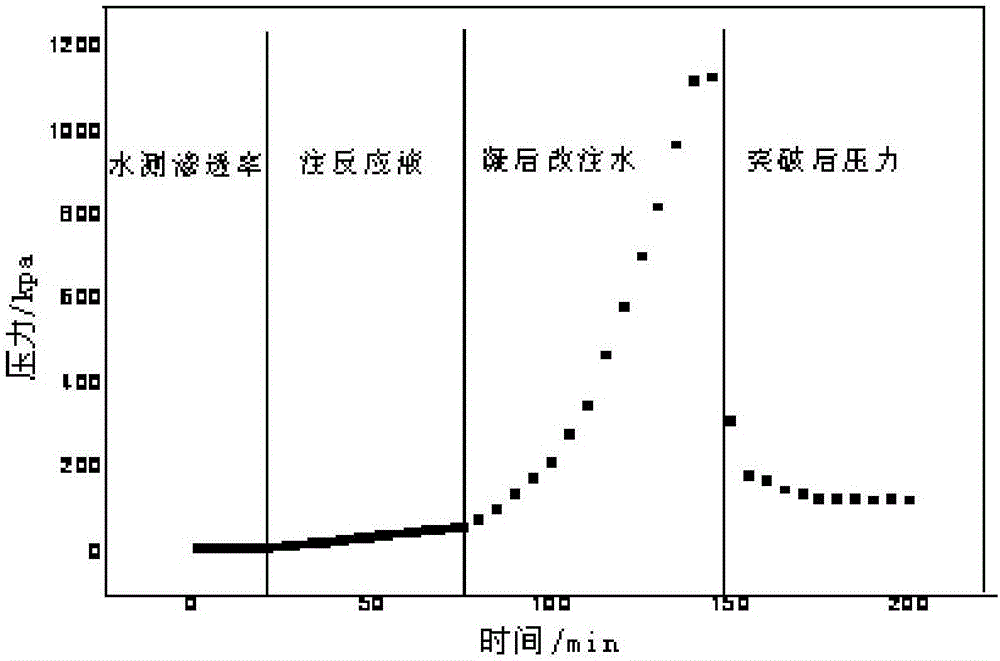

[0029] A physical model experiment was used to evaluate the plugging performance of the gel plugging modifier prepared in Example 2. The plugging adjustment system solution prepared according to the method of Example 2 is ready for use. Fill sand tubes with a length of 100cm wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drag coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com