Steel structure fireproof paint

A technology of fire-resistant coatings and steel structures, applied in fire-resistant coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., to achieve good anti-corrosion and outstanding fire-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

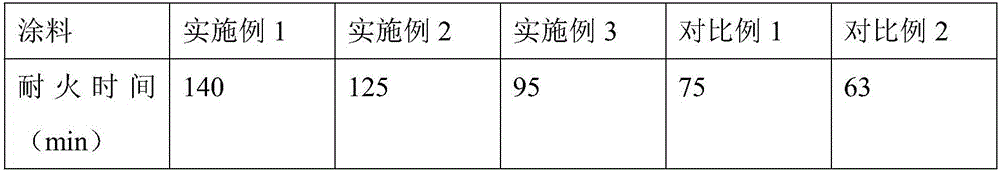

Examples

experiment example 1

[0024] Experimental example 1 A kind of steel structure fireproof coating

[0025] A fireproof coating for steel structures, which is composed of the following components in weight percentage: 14.86% of cycloaliphatic epoxy resin, 14.86% of brominated bisphenol A epoxy resin, 7.43% of methylphenyl silicone resin, and 22.29% of acrylic resin , Melamine 4%, Pentaerythritol 3%, Ammonium Polyphosphate 6%, Antimony Oxide 1%, Zinc Borate 2%, Cuprous Oxide 2.5%, Vermiculite 2.25%, Aluminum Polyphosphate 4%, Zinc Oxide 2.5%, Leveling Agent 0.75%, Acetone 17%, 1,2-Benzisothiazolin-3-one 1.5%, Butylparaben 1.5%.

[0026] The preparation method of the coating: first, cycloaliphatic epoxy resin, brominated bisphenol A type epoxy resin, methylphenyl silicone resin, acrylic resin, melamine: pentaerythritol, ammonium polyphosphate, antimony oxide, zinc borate, oxidation Cuprous, vermiculite, aluminum polyphosphate, zinc oxide are crushed, then the crushed raw materials are mixed with leveli...

Embodiment 2

[0027] Embodiment 2 A kind of steel structure fireproof coating

[0028] A fireproof coating for steel structures, which is composed of the following components by weight percentage: 10% cycloaliphatic epoxy resin, 10% brominated bisphenol A epoxy resin, 5% methylphenyl silicone resin, and 15% acrylic resin , Melamine 3%: Pentaerythritol 2%: Ammonium Polyphosphate 7%: Antimony Oxide 1%, Zinc Borate 2%, Cuprous Oxide 1%, Vermiculite 0.5%, Aluminum Polyphosphate 2%, Zinc Oxide 1%, Leveling Agent 0.5%, acetone 15%, 1,2-benzisothiazolin-3-one 1%, butylparaben 1%.

[0029] The preparation method is similar to Example 1.

Embodiment 3

[0030] Embodiment 3 A kind of steel structure fireproof coating

[0031] A fireproof coating for steel structures, which is composed of the following components by weight percentage: 15% cycloaliphatic epoxy resin, 15% brominated bisphenol A epoxy resin, 7.5% methylphenyl silicone resin, and 22.5% acrylic resin , Melamine 4.4%, Pentaerythritol 3.3%, Ammonium Polyphosphate 8.8%, Antimony Oxide 1.1%, Zinc Borate 2.2%, Cuprous Oxide 3%, Vermiculite 3%, Aluminum Polyphosphate 5%, Zinc Oxide 3%, Leveling Agent 1%, Acetone 20%, 1,2-Benzisothiazolin-3-one 5%, Butylparaben 5%.

[0032] The preparation method is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fire resistance time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com