Preparation method for sodium fatty acyl methyl taurate

A technology of sodium fatty acyl methyl taurate and sodium methyl taurate, which is applied in the preparation of high-purity sodium fatty acyl methyl taurate and the field of preparation of fatty acyl amino acid type anionic surfactants, can solve many problems Difficult to acidify stratification, large salty wastewater, large equipment investment and other problems, to achieve the effect of reducing crystal solubility, advanced and reasonable technology, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

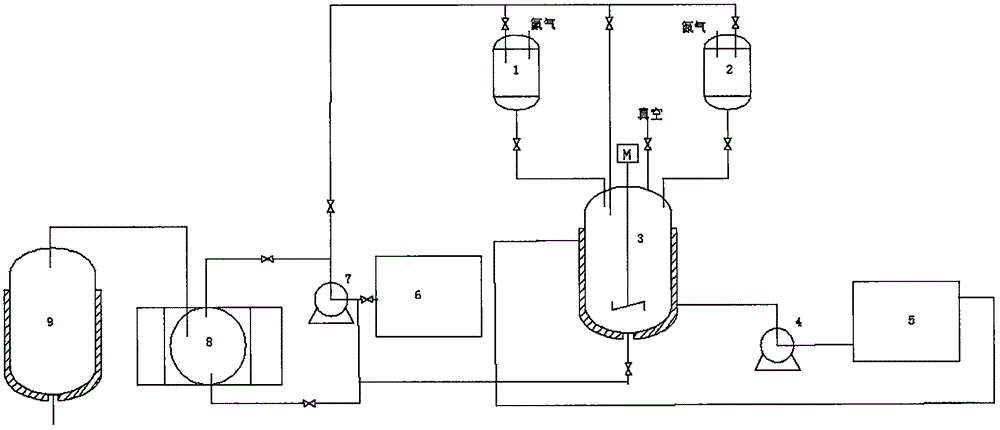

Method used

Image

Examples

Embodiment 1

[0027] Under room temperature, 1110kg of N-methyl taurine sodium solution (40%) is pumped into the reactor, stirred and mixed for 30min, added 1110kg of reclaimed filtrate, continued to stir and mixed for 30min; 218) into the high level tank respectively, and feed nitrogen gas of 0.02-0.05MPa for nitrogen blanketing; adjust the pH of the system at 12, and the temperature ≤ 40°C; start to drop acid chloride and liquid caustic soda at the same time, and control the pH at 9-11 during the dropping process. When the temperature is ≤65°C, the dropping time is controlled within 2 hours; after the dropping is completed, the temperature is raised to 70°C, and the temperature is kept and aged for 4 hours;

[0028] Under stirring at 60RPM, vacuum pump 1250kg of recovered filtrate at 0°C, and drop the temperature to 50°C; at the same time, reduce the stirring to 15RPM, and control the cooling rate at 10 minutes / 1°C through refrigerated circulating water, and slowly cool down to 5°C , free...

Embodiment 2

[0032]Under room temperature, N-methyl taurine sodium solution (40%) 1200kg is sucked into reactor, stirs and mixes 30min, adds 300kg and reclaims filtrate, continues to stir and mix 30min; =218) into the head tank respectively, and nitrogen gas 0.02-0.05MPa was introduced to carry out nitrogen blanketing; adjust the pH of the system at 12, the temperature ≤ 40°C; start to add acid chloride and liquid caustic soda at the same time, and control the pH at 9-11 during the dropping process , the temperature is ≤65°C, and the dropping time is controlled at 6 hours; after the dropping is completed, the temperature is raised to 65°C, and the aging is kept for 2 hours;

[0033] Under 50RPM stirring, vacuum pump 2480kg of recovered filtrate at 0°C, and the temperature will drop to 30°C; at the same time, reduce the stirring to 5RPM, and control the cooling rate at 5 minutes / 1°C through refrigerated circulating water, and slowly cool down to 0°C , frozen and crystallized for 25 hours; ...

Embodiment 3

[0037] At room temperature, 1200 kg of N-methyl taurine sodium solution (40%) is sucked into the reactor, stirred and mixed for 30 min, added 1500 kg of reclaimed filtrate, continued to stir and mixed for 30 min; = 246.82) respectively into the high level tank, and nitrogen gas 0.02 ~ 0.05MPa was introduced to carry out nitrogen blanketing; adjust the pH of the system at 12, and the temperature ≤ 40 ° C; start to drop acid chloride and liquid caustic soda at the same time, and control the pH at 9 ~ 11 during the dropping process , the temperature is ≤65°C, and the dropping time is controlled at 6 hours; after the dropping is completed, the temperature is raised to 85°C, and the temperature is kept and aged for 3 hours;

[0038] Under 70RPM stirring, vacuum pump 1500kg of recovered filtrate at 0°C, and the temperature in the kettle will drop to 50°C; at the same time, reduce the stirring to 20RPM, and control the cooling rate at 5 minutes / 1°C through refrigerated circulating wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com