Dicyclopentadiene decolorizing method

A dicyclopentadiene, removal technology, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve problems such as greenish color, product chroma not up to standard, affecting downstream product production, etc., to achieve no waste water Emissions, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

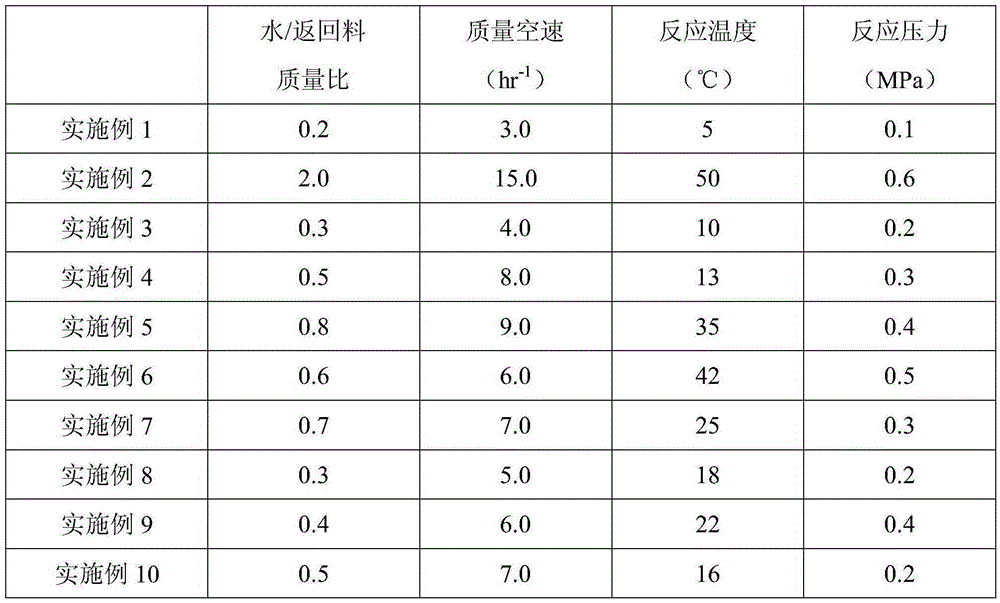

Embodiment 1~10

[0019] 1. Return materials

[0020] The returned material used in Examples 1-10 comes from a part of the material produced by the C5 separation device during the production of isoprene. The composition of the returned material is shown in Table 1.

[0021] Table 1.

[0022] components return material(1) Return material (2) Total C4,% 0.00 0.04 3-Methylbutene-1,% 0.01 0.00 1.4-Pentadiene,% 0.07 0.00 Butyne-2,% 1.17 0.02 Prenyne,% 0.00 1.91 2-Methylbutene-1,% 0.02 0.00 Isoprene,% 98.23 97.15 2-Methylbutene-2,% 0.00 0.05 Cyclopentadiene,% 0.00 0.26 Cyclopentene,% 0.00 0.48 Other C5,% 0.00 0.08 Dimethylamine,% 0.5 0.01 pH 11 9

[0023] 2. Return material removes dimethylamine

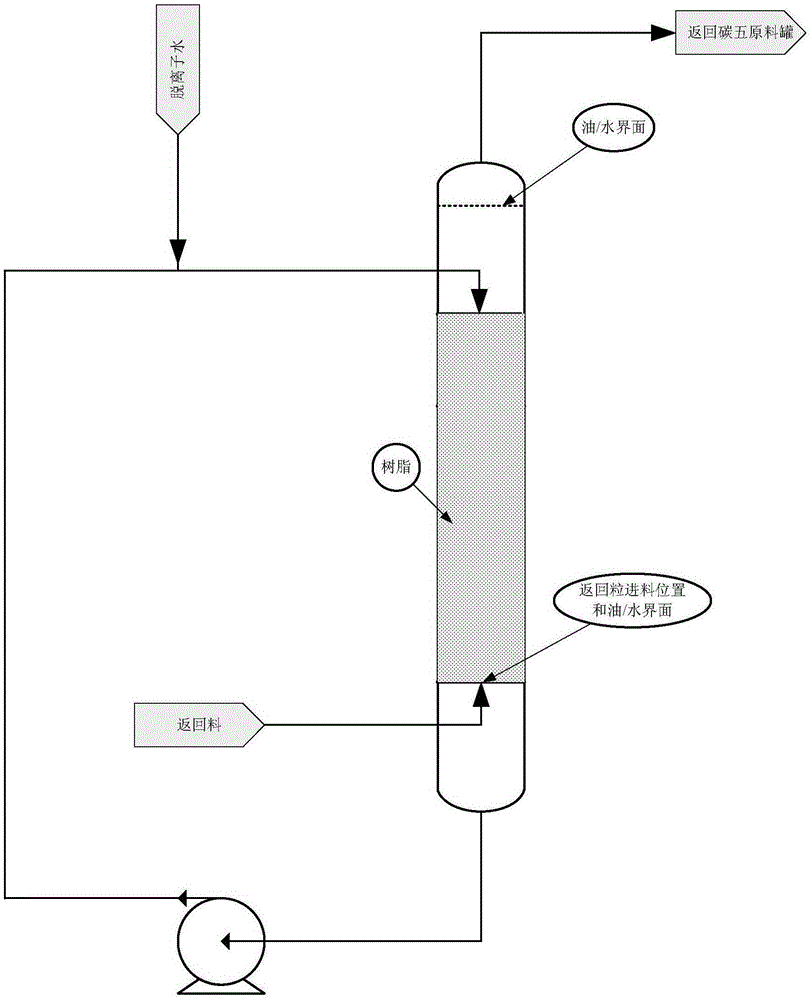

[0024] The return material is as in figure 1 The removal of dimethylamine takes place in the water wash column shown. The size of the washing tower is 100 grams of spherical sulfonic acid-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com