Filter disc type microporous aerator provided with rubber diaphragm

A microporous aerator, rubber membrane technology, applied in water aeration, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of affecting the normal operation of the system, entering the ventilation duct system, and affecting the next use and other problems, to achieve the effects of excellent thermal stability, stable system operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

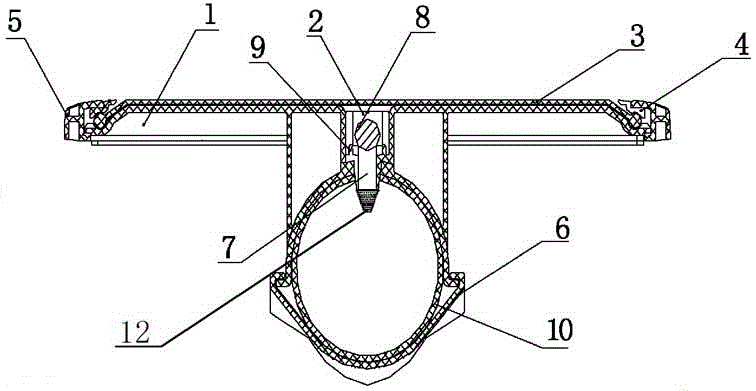

[0023] Such as figure 1 and figure 2 Shown: This embodiment provides a filter-type disc-type rubber membrane microporous aerator, including a main body 1, a check valve 2, a diaphragm 3, a telescopic ring 4, a gland 5 and a wedge 6; the check valve 2 is arranged in the air inlet 7; a steel ball 8 is arranged in the check valve 2, and a diaphragm 3 and a telescopic ring 4 are arranged in sequence at the upper end of the check valve 2.

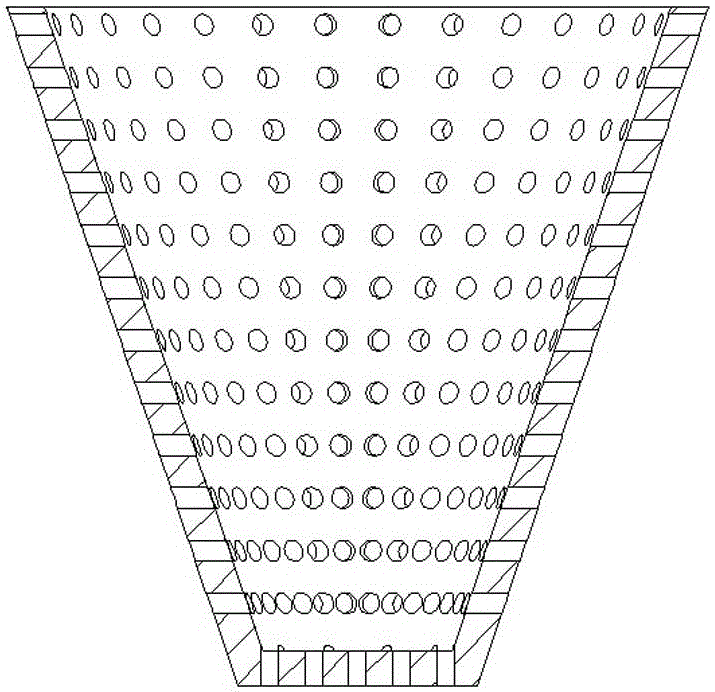

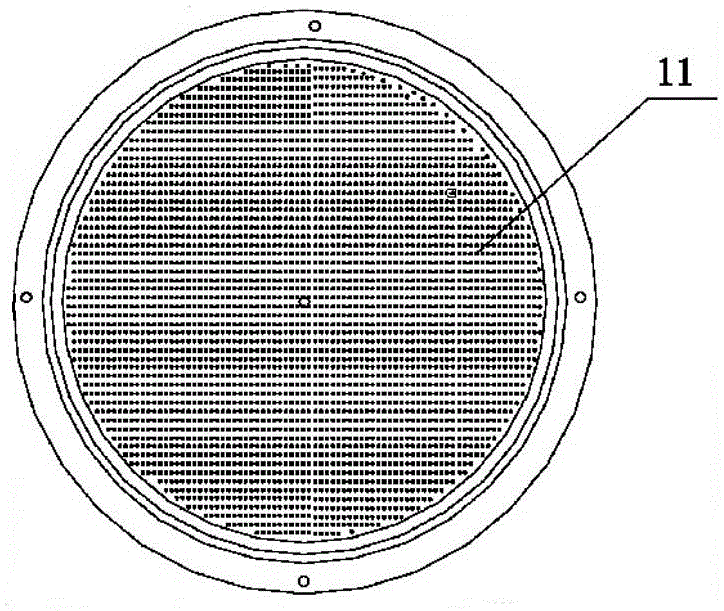

[0024] The diaphragm 3 and the telescopic ring 4 are fixedly connected by the gland 5, and the diaphragm 3 is provided with a microhole 11, the diameter of which is φ1.2mm. 2 The lower end is provided with a filter 12, the shape of the filter 12 is conical, and the upper end of the check valve 2 is covered with a sealing ring 9, and the sealing ring 9 is an O-shaped sealing ring 9.

[0025] The working process of this embodiment is: when the system is working, the air first passes through the filter 12, then passes through the check valve 2, ...

Embodiment 2

[0028]The structure of this embodiment is the same as that of Example 1, the difference lies in the composition of the sealing ring, the material of the sealing ring of this embodiment is a composite polypropylene material, including a polypropylene matrix and a reinforcement system, and the components in parts by weight of the polypropylene matrix include : Polypropylene resin: 96 parts, 3-hydroxypropionitrile: 2 parts, o-methylhydroquinone: 0.4 parts, nucleating agent: 2.7 parts, antioxidant: 3.2 parts, lubricant: 1.3 parts, filler: 6.6 parts; the addition of the reinforcement system is 4% of the weight of the polypropylene matrix; the components of the reinforcement system are composed of: nano silicon dioxide: 11.8 parts, ethoxylated alkylamine: 26 parts , methyl hydrogen silicone oil: 82 parts, ammonium polyphosphate: 2.6 parts, chopped glass fiber: 8 parts, fumed silica: 4.6 parts, γ-aminopropyltriethoxysilane: 8 parts, toughening Agent: 3.8 parts, reactive diluent: 1.6 ...

Embodiment 3

[0030] The structure of this embodiment is the same as that of Example 1, the difference lies in the composition of the sealing ring, the material of the sealing ring of this embodiment is a composite polypropylene material, including a polypropylene matrix and a reinforcement system, and the components in parts by weight of the polypropylene matrix include : Polypropylene resin: 97 parts, 3-hydroxypropionitrile: 3 parts, o-methylhydroquinone: 0.5 parts, nucleating agent: 2.8 parts, antioxidant: 3.3 parts, lubricant: 1.5 parts, filler: 6.7 parts; the addition of the reinforcement system is 5% of the weight of the polypropylene matrix; the components of the reinforcement system are composed of: nano silicon dioxide: 11.9 parts, ethoxylated alkylamine: 27 parts , methyl hydrogen silicone oil: 83 parts, ammonium polyphosphate: 2.7 parts, chopped glass fiber: 9 parts, fumed silica: 4.7 parts, γ-aminopropyl triethoxysilane: 9 parts, toughening Agent: 3.9 parts, reactive diluent: 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com