Composite scale and corrosion inhibitor containing sodium polyepoxysuccinate and preparation method thereof

A technology of sodium polyepoxysuccinate, scale and corrosion inhibitor, applied in chemical instruments and methods, scale removal and water softening, special treatment targets, etc., can solve the problems of low scale inhibition rate and corrosion inhibition rate, etc. The effect of smooth and strong bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

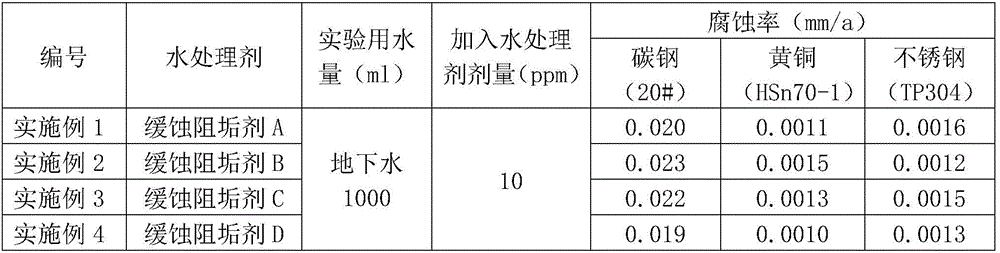

Embodiment 1

[0040] A preparation method of a composite scale and corrosion inhibitor containing sodium polyepoxysuccinate, the operation steps are as follows:

[0041] step 1,

[0042] Weigh 280g of sodium polyepoxysuccinate, 100g of benzotriazole, 200g of sodium acrylate-hydroxyethyl methacrylate-methyl acrylate copolymer, 200g of tetrakis hydroxymethyl phosphorus sulfate, 120g of zinc sulfate and 100g of deionized water.

[0043] Step 2,

[0044] First add deionized water to the reaction equipment, then add benzotriazole while stirring, stir and mix well, then add sodium polyepoxysuccinate while stirring, and then add tetramethylol while stirring Phosphorus sulfate, after stirring and mixing, then add zinc sulfate while stirring, and finally add sodium acrylate-hydroxyethyl methacrylate-methyl acrylate copolymer while stirring, wait for stirring and mixing to obtain corrosion inhibitor Detergent A.

[0045] Wherein, the synthetic steps of above-mentioned sodium polyepoxysuccinate ar...

Embodiment 2

[0053] A preparation method of a composite scale and corrosion inhibitor containing sodium polyepoxysuccinate, the operation steps are as follows:

[0054] step 1,

[0055] Take by weighing the sodium polyepoxysuccinate of 200g, the benzotriazole of 40g, the tetrakis hydroxymethyl phosphorus sulfate of the sodium acrylate-hydroxyethyl methacrylate-methyl acrylate copolymer 110g of 150g, the zinc sulfate of 100g and 400g of deionized water.

[0056] Step 2,

[0057] First add deionized water to the reaction equipment, then add benzotriazole while stirring, stir and mix well, then add sodium polyepoxysuccinate while stirring, and then add tetramethylol while stirring Phosphorus sulfate, after stirring and mixing, then add zinc sulfate while stirring, and finally add sodium acrylate-hydroxyethyl methacrylate-methyl acrylate copolymer while stirring, wait for stirring and mixing to obtain corrosion inhibitor Detergent B.

[0058] Wherein, the synthetic steps of above-mentioned...

Embodiment 3

[0066] A preparation method of a composite scale and corrosion inhibitor containing sodium polyepoxysuccinate, the operation steps are as follows:

[0067] step 1,

[0068] Weigh 220g of sodium polyepoxysuccinate, 80g of benzotriazole, 170g of sodium acrylate-hydroxyethyl methacrylate-methyl acrylate copolymer, 150g of tetrakis hydroxymethyl phosphorus sulfate, 200g of zinc sulfate and 180g of deionized water.

[0069] Step 2,

[0070] First add deionized water to the reaction equipment, then add benzotriazole while stirring, stir and mix well, then add sodium polyepoxysuccinate while stirring, and then add tetramethylol while stirring Phosphorus sulfate, after stirring and mixing, then add zinc sulfate while stirring, and finally add sodium acrylate-hydroxyethyl methacrylate-methyl acrylate copolymer while stirring, wait for stirring and mixing to obtain corrosion inhibitor Detergent C.

[0071] Wherein, the synthetic steps of above-mentioned sodium polyepoxysuccinate are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com