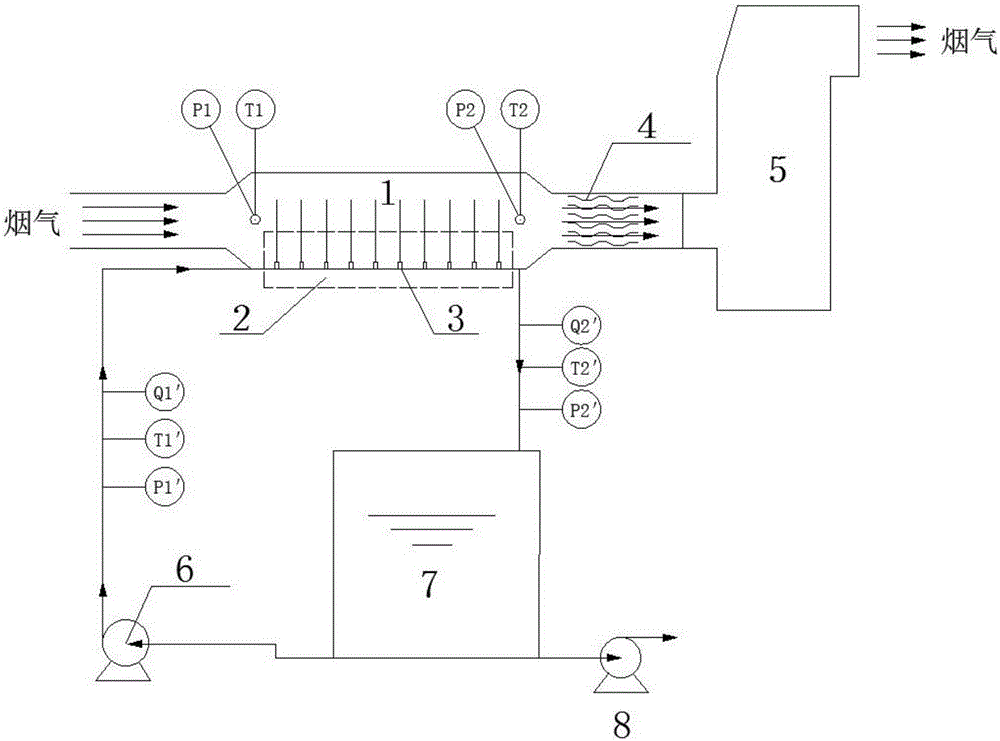

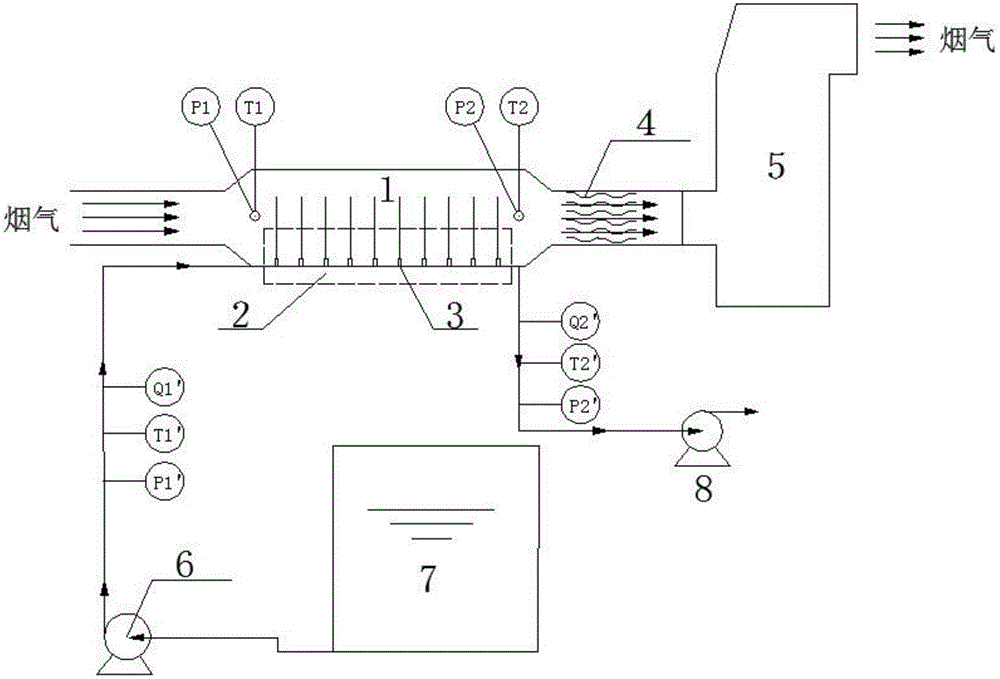

Wastewater concentrating system and method utilizing flue gas waste heat and based on liquid column evaporation

A waste water concentration and flue gas waste heat technology, which is applied in the field of energy and environment, can solve the problems of wall area ash, nozzles are easy to block, etc., and achieve the effect of reducing desulfurization water replenishment, reducing desulfurization tower pressure, and reducing treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Take the concentrated circulating water of 300MW unit as an example. Standard flue gas flow is about 1000000Nm 3 Coal-fired power plants with a flow rate of 100t / h and a total salt content of 3000mg / L, the circulating water drainage is pumped into the spray area of the evaporation tower through the wastewater circulation pump, and sprayed into the evaporation tower through the nozzle hole to directly contact with the flue gas for heat transfer After concentration, the waste water is discharged into the waste water storage pool through the outlet of the lower part of the evaporation tower, and is further circulated and evaporated and concentrated by the waste water circulation pump. After being concentrated to a total salt content of 60000mg / L and a waste water flow rate of 5t / h, it is discharged through the waste water discharge pump. Proceed to the next step.

Embodiment 2

[0052] Take the concentrated desulfurization wastewater of a 300MW unit as an example. Standard flue gas flow is about 1000000Nm 3 / h, the desulfurization wastewater of coal-fired power plants with a flow rate of 10t / h and a total salt content of 30000mg / L is pumped into the spray area of the evaporation tower through the wastewater circulation pump, and sprayed into the evaporation tower through the nozzle hole to directly contact with the flue gas for heat transfer Quality, the total salt content of the concentrated wastewater is 150,000mg / L, and the flow rate is 2t / h. It is directly discharged through the outlet at the lower part of the evaporation tower for the next step of treatment. The difference from the process flow of Example 1 is that when the required concentration ratio of the wastewater is low, the concentrated wastewater at the outlet of the evaporation tower does not need to enter the wastewater storage tank for circulation and concentration, but is directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com