Storage mechanism and carrying device and storage and retrieval method thereof

A handling device and storage technology, which is applied in the field of storage mechanism and its handling device, can solve the problems of restricted size of goods to be accessed, large occupied area, low use efficiency, etc., and achieve the effect of high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

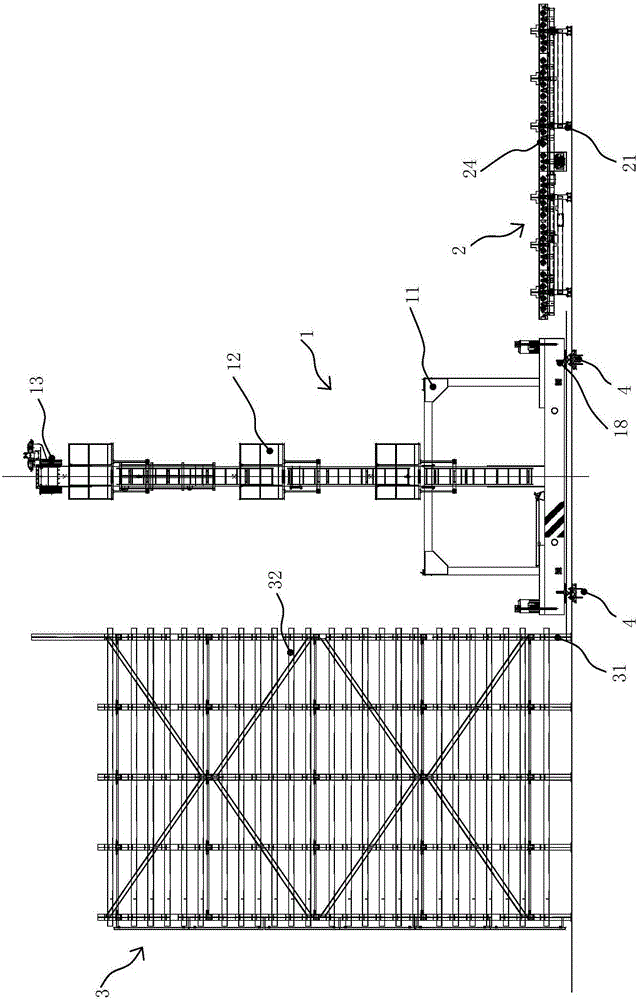

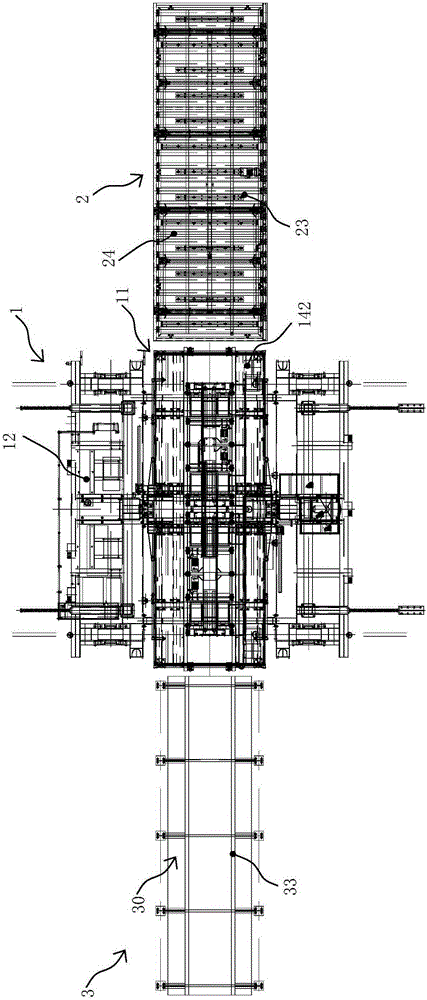

[0065] refer to Figure 1 to Figure 6 Shown is the first embodiment of the handling device of the storage mechanism of the present invention, and the handling device can be applied to a three-dimensional warehouse. Here, as figure 1 As shown, the handling device is applied as a stacker 1 of the three-dimensional warehouse, the main frame is used as the loading platform 11 of the stacker 1;

[0066] Among them, such as figure 1 , figure 2 As shown, the stacker 1 is generally located in the roadway of the three-dimensional warehouse, and the second track 4 is arranged in the roadway. The lower side of the stacker 1 has a walking mechanism 18. Using the walking mechanism 18, the stacker 1 can move in the roadway. Move horizontally.

[0067] Such as Figure 3 to Figure 5 As shown, the stacker 1 has a loading platform 11 , a support 12 , a lifting mechanism 13 , a conveyor 14 and a carrier 15 . And the first track 16 and the side track 17 for article carrier 15 walking can be...

no. 2 example

[0085] refer to Figure 7 to Figure 13 Shown, is the second embodiment of the handling device of the storage mechanism of the present invention, and the handling device can be applied to a three-dimensional garage, where, as figure 1 As shown, the handling device is applied to the middle sports car 5 of the three-dimensional garage, the main frame is applied to the carrier platform 51 of the middle sports car 5;

[0086] Such as Figure 7 , Figure 8 and Figure 9 As shown, the middle sports car 5 has a loading platform 11 , a conveyor 54 and a carrier 55 . A belt conveyor 54 and a holding carrier 55 can be installed on the stage 51 at the same time. The carrier 51 is a platform capable of lateral movement and / or vertical lift, so as to transport the automobile B to the designated parking space 70 of the three-dimensional parking space 7 . A first rail 56 for holding the carrier 55 can be installed on the stage 51 , and the first rail 56 is parallel to the first direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com