Automatic discharging machine

A technology of automatic blanking and transmission mechanism, which is applied in metal processing and other directions, can solve the problems of uneven incision, defective products, and low work efficiency, and achieve the effect of smooth and complete incision, consistent moment of inertia, and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

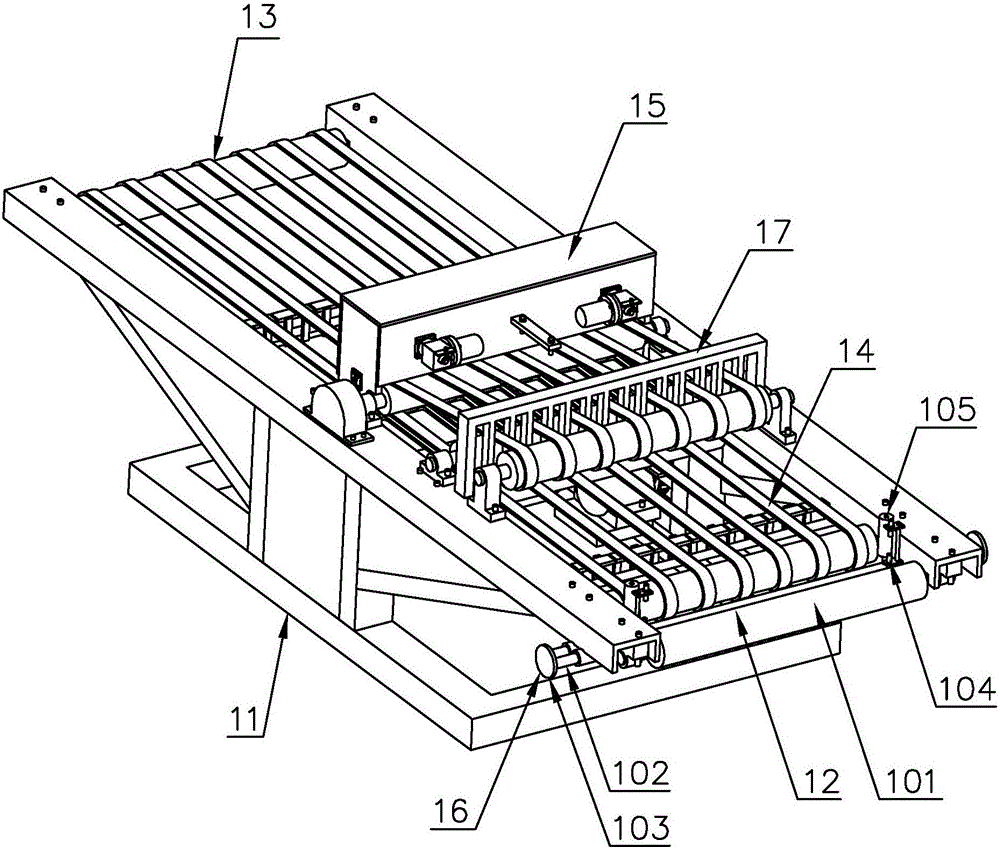

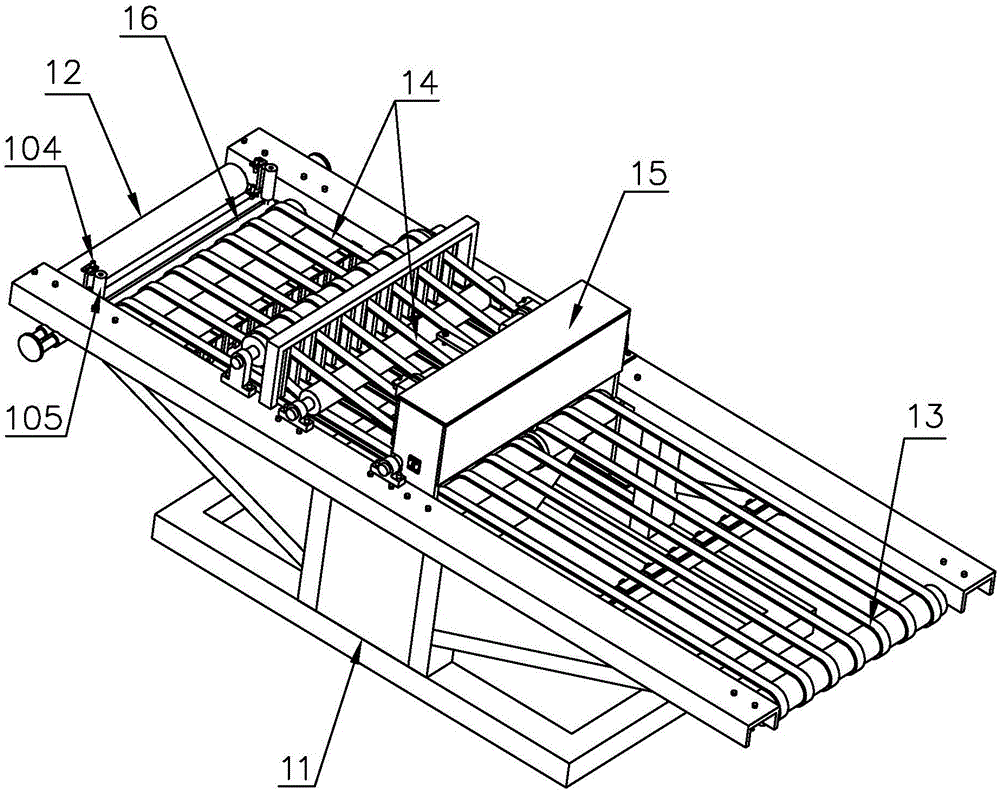

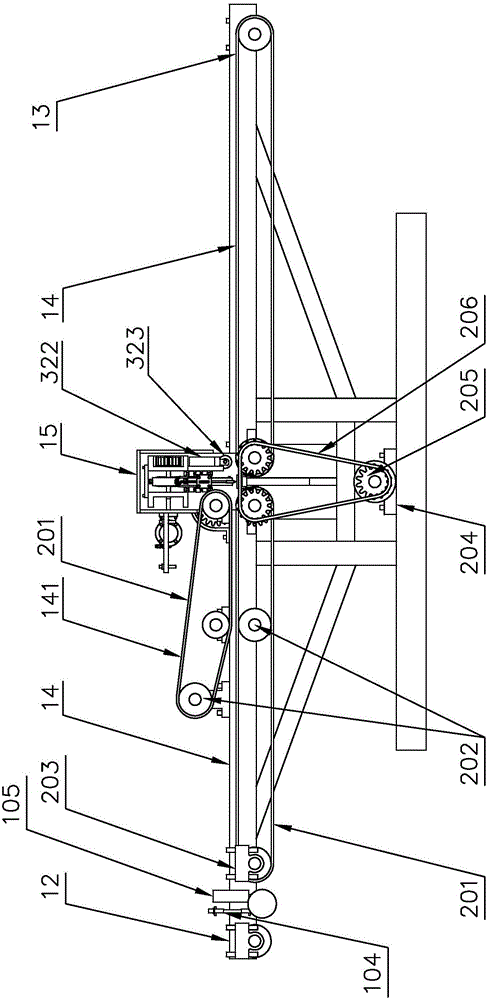

[0035] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-8 , to further specifically describe the technical solution of the present invention.

[0036] An automatic blanking machine, comprising a frame 11, a feed port 12, a discharge port 13, a transmission mechanism 14, a skin clamping mechanism 141, and a skin cutting mechanism 15, one end of the frame 11 is provided with a feed port 12, and the machine Frame 11 other end is provided with discharge port 13, and frame 11 is provided with transmission mechanism 14, and transmission mechanism 14 is movably linked on the frame 11 by bearing 203, and transmission mechanism 14 top is provided with clamping mechanism 141, and clamping mechanism 141 One side is provided with slicing mechanism 15, and frame is used for bearing transmission mechanism 14, skin clamping mechanism 141, peeling mechanism 15.

[0037] The transmission mechanism 14 comprises a feed end t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com