Self-centering outer-diameter clamp

A self-centering and fixture technology, applied in the field of machining, can solve the problems of inability to achieve self-centering, poor machining accuracy, complex structure, etc., and achieve the effects of simple structure, improved machining accuracy, and reliable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

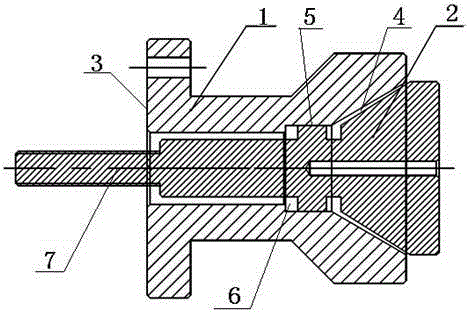

[0009] Depend on figure 1 It is known that a self-centering outer diameter clamp is composed of a clamp base 1, a clamp rod 2, a contraction surface 3, a guide surface 4, a mounting surface 5, and a spindle connecting thread 6. The clamp rod 2 is inserted into the clamp base 1 Inside, the fixture is positioned by the guide step and the guide surface 4, the shrinkage surface 3 is an inner cone surface, the shrinkage body is an outer cone structure, and the included angle of the inner cone surface is smaller than the included angle of the outer cone, so The above-mentioned contraction body is connected with the guide step, and the connecting part is provided with a contraction avoidance groove, and the center of the contraction body part is provided with a central hole, and six notches of equal depth are arranged concentrically and evenly along the center hole to the outer edge of the vertebral body. The contraction body is divided into six parts. When making the fixture, first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com