Flow deflector shearing device of isolating switch

A technology of shearing device and isolating switch, which is applied in metal processing and other directions, can solve the problems of personal safety hazards, oxidation, and affecting the electrical conductivity of isolating switch products, etc., and achieve the effect of improving the shearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

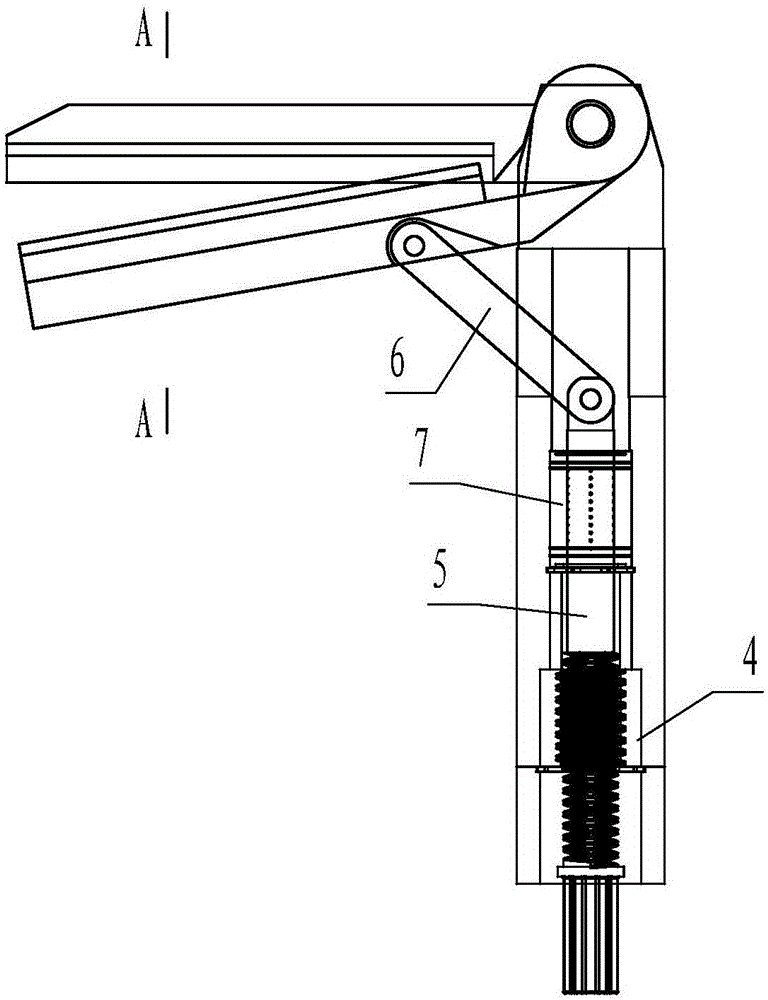

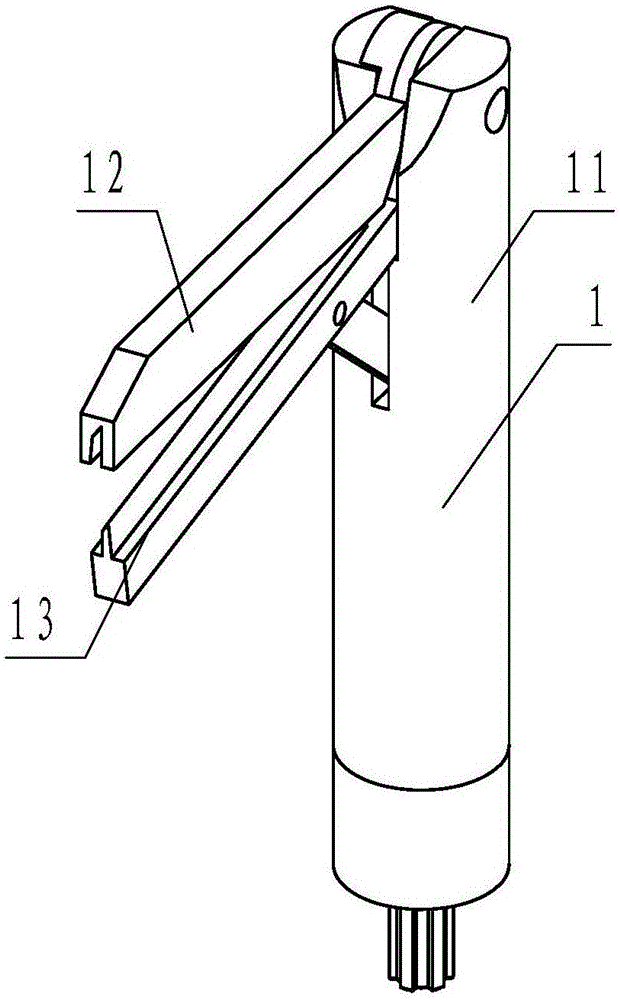

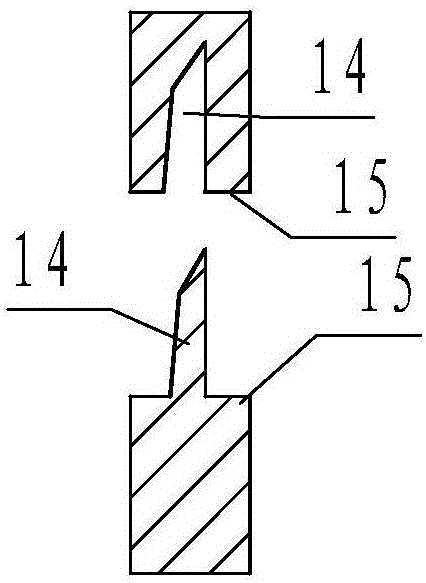

[0029] A kind of isolating switch deflector cutting device, comprises cutting head 1, driving device 2 and operating rod 3, and described cutting head includes knife rest 11, upper blade 12 and lower blade 13, and described upper 1. The lower blade is installed on the knife holder, and the working surface of the upper and lower blades includes a knife edge 14 and a clamping plane 15, and the clamping plane is a plane arranged on the knife edge side. The working surfaces of the upper and lower blades are provided with protrusions on the plane of one blade, and grooves matched with the protrusions are arranged on the plane of the other blade, and the protrusions and grooves form the edge of the knife. The plane forms the clamping surface. The protrusions and grooves are arranged in the middle of the plane. The knife rest is a tubular body, and a nut screw device is arranged in the tubular body of the knife rest. The nut 4 is fixed in the inner cavity of the tubular body of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com