A mesh needle claw

A needle claw and mesh technology, applied in the field of mesh needle claws, can solve the problems of unfavorable control costs, low efficiency, high labor intensity, etc., and achieve the effects of rapid action, convenient use, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

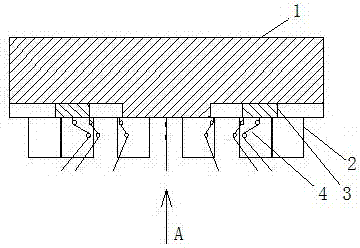

[0020] Such as figure 1 and figure 2 The mesh needle jaw shown includes a pneumatic chuck 1, and the 12 movable jaws 3 of the chuck 1 are respectively equipped with spring steel spring steel springs whose needle tip is inclined at 30°~60° and extends outward. The more the number of needles 4, movable jaws 3 and corresponding elastic needles 4, the higher the probability of effectively inserting into the mesh, and the lower the possibility of grasping failure. On the chuck 1 between the adjacent movable jaws 3 There is also a spacer 2 with a height smaller than the elastic needle 4, the elastic needle 4 is composed of an upper part, a middle part extending obliquely inward, and a lower part extending obliquely outward, and the two ends of the middle part are respectively connected to the upper part and the upper part by torsion springs. Bottom, the upper surface of the movable jaw 3 is provided with a mounting hole, and the side is provided with a screw hole communicating wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com