A kind of extreme ultraviolet multilayer film and preparation method thereof

A multi-layer film, extreme ultraviolet technology, applied in the photoplate process, instruments, optics and other directions of the pattern surface, can solve the problems of affecting the imaging quality and shorten the service life of the system, and achieve the effect of spectral purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

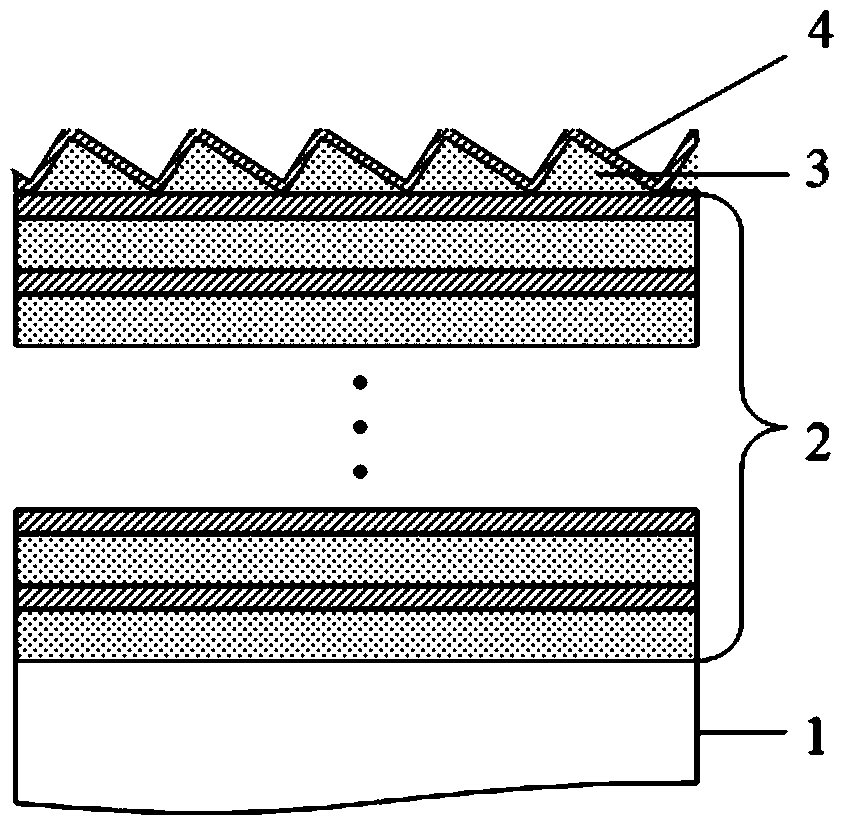

[0026] On the other hand, the present invention also provides a method for preparing an extreme ultraviolet multilayer film, comprising steps: S1, preparing a substrate; S2, preparing multiple cycles of Si / Mo layers on the substrate by magnetron sputtering ; S3, preparing a zigzag array structure layer on the Si / Mo layer; S4, depositing an infrared reflection layer on the zigzag array structure layer by magnetron sputtering.

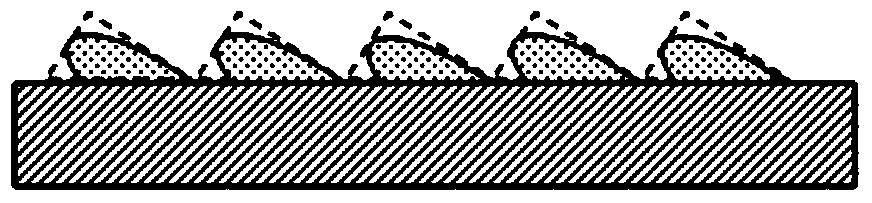

[0027]Specifically, in one embodiment, the method for preparing an extreme ultraviolet multilayer film according to the present invention may include steps, step 1, preparing a fused silica substrate 1 with a roughness of 0.2nm; step 2, using magnetron sputtering to prepare 40 cycles Mo / Si layer 2, period 7nm, gamma value 0.4; step 3, using grazing angle deposition technology, depositing Si nanowires with an inclination angle of 30° on the surface of the multilayer film to form a triangular-like array structure 3, such as figure 2 As shown; step 4, usin...

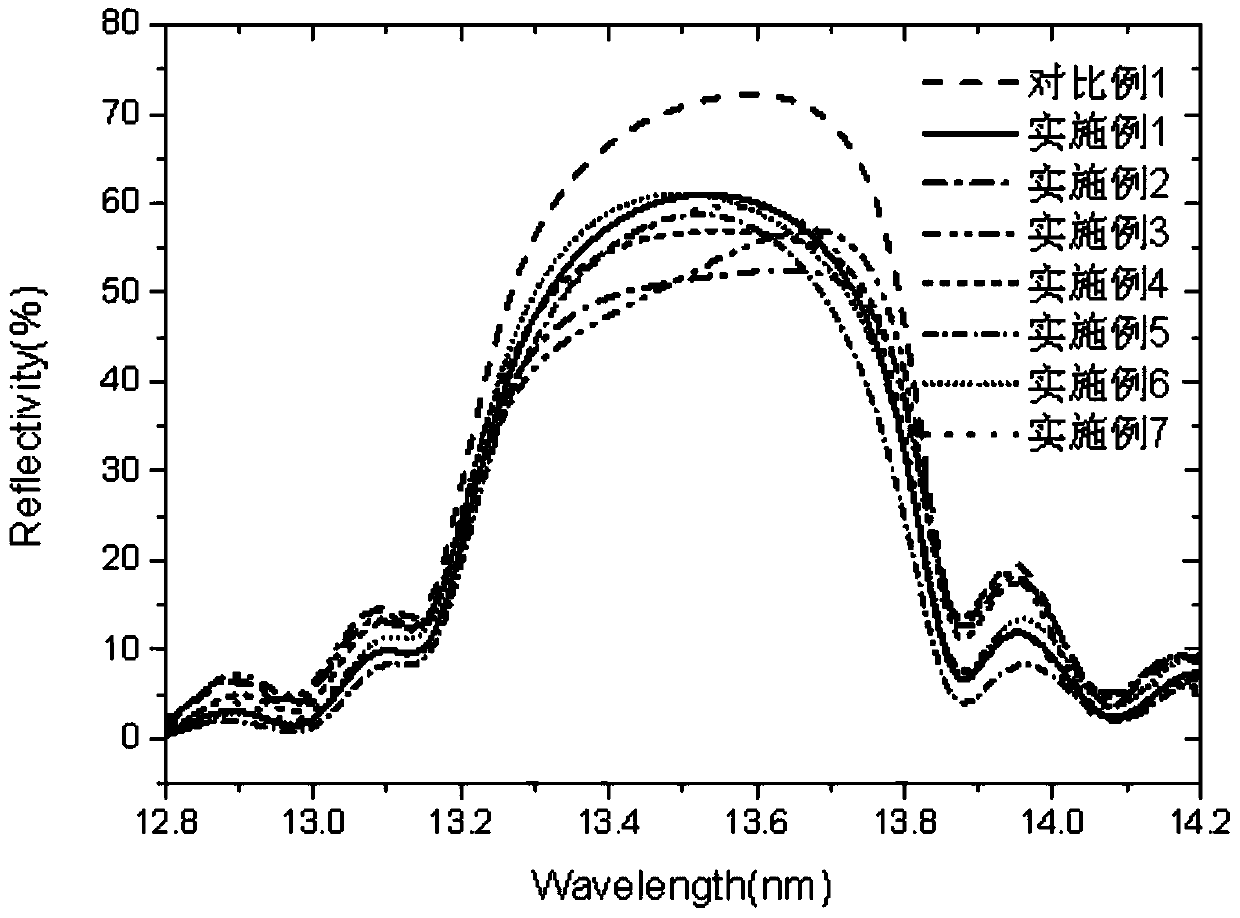

Embodiment 1-7

[0033] The extreme ultraviolet multilayer film with infrared spectroscopic function comprises a substrate 1, a plurality of periodic Si / Mo layers 2, a zigzag array structure layer 3 and an infrared reflection layer 4 from bottom to top. The materials and thicknesses used in Examples 1-7 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com