A hydrocyclone separation method and device, and an electric power control method for an inner cylinder magnetic core

A technology of electric power control and hydrocyclone, which is applied in the direction of cyclone device, etc., can solve the problems that oil and water cannot be fully separated, the water content index is difficult to achieve, and the viscosity of oil-water emulsion is large, so as to facilitate oil-water separation and promote oil-water The effect of separation, low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

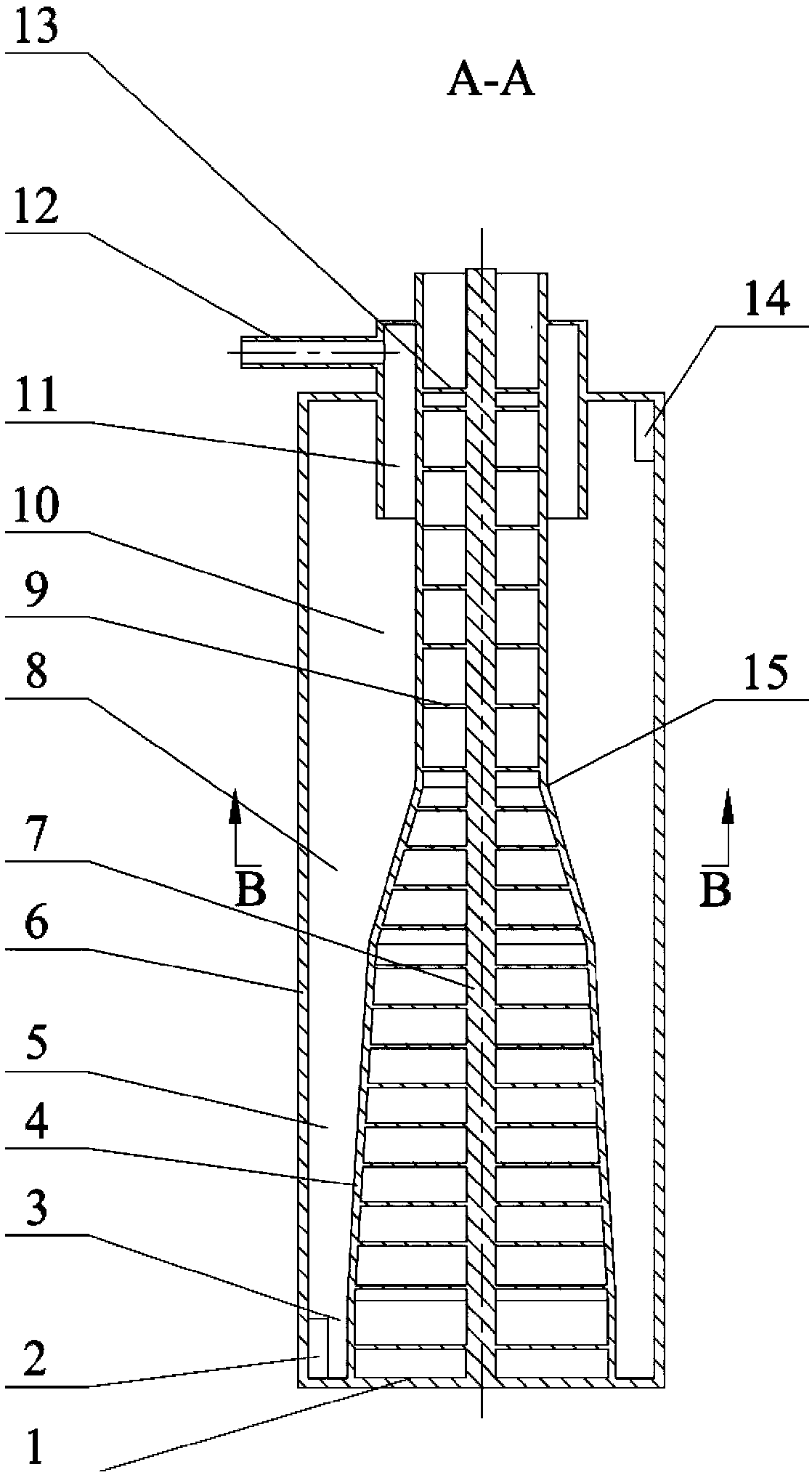

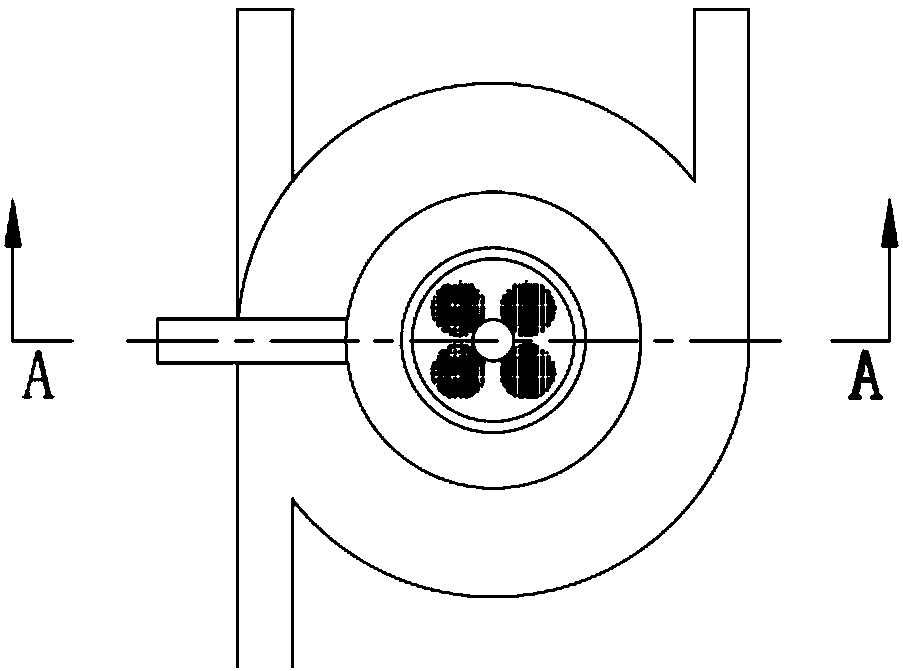

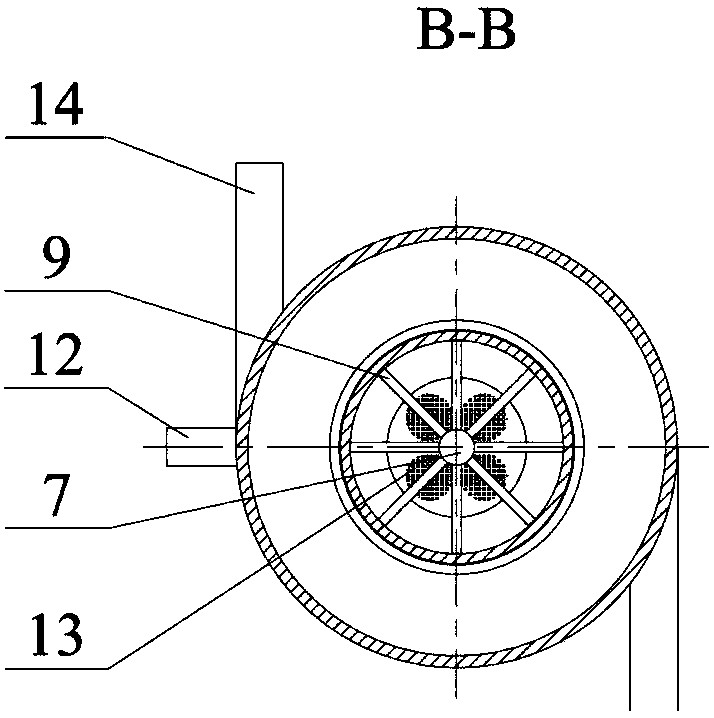

[0025] The present invention will be further explained below in conjunction with the drawings:

[0026] First, the purpose of the present invention is explained: in order to improve the separation efficiency of the existing hydrocyclone and expand the applicable range of the cyclone, a magnetic core hydrocyclone is designed. The main purposes are: (1) Improve the efficiency of cyclone separation processing; (2) Combine electromagnetic field with mechanical structure using complete physical method to provide new ideas for oil-water emulsion demulsification and separation, and promote the development of separation technology; ( 3) It can treat different types of oil-water mixtures, expand the application range of swirling separation, and can be widely used in crude oil dehydration, sewage degreasing, oil refinery slop oil recovery, automobile lubricating oil recovery and other fields.

[0027] In order to achieve the above objectives, the present invention first proposes a new method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com