Method for synthesizing 3-hydroxyl oxoindole derivative

A technology of indole derivatives, hydroxyl oxidation, applied in organic chemistry and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

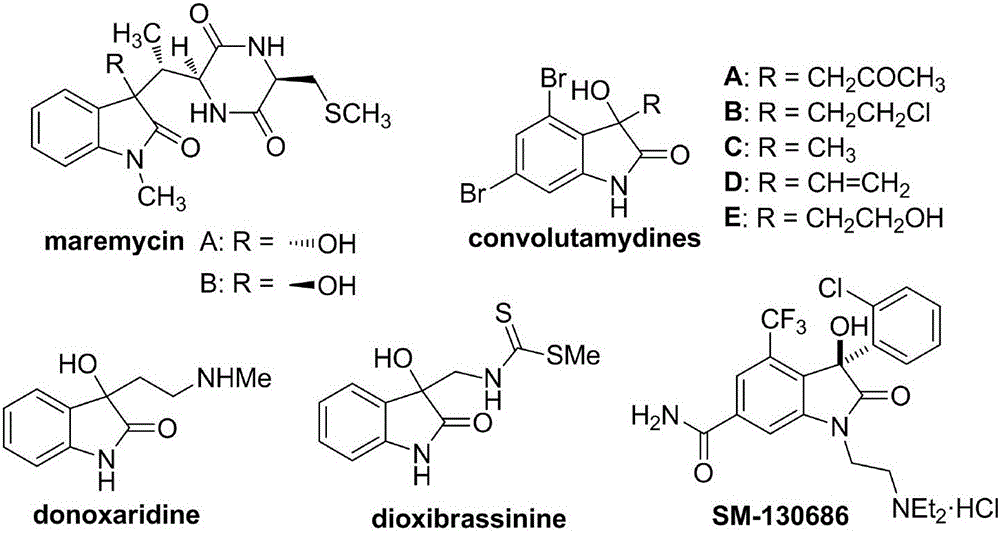

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074]

[0075] In this example: R 1 is methyl; R 2 is hydrogen; R 3 for hydrogen.

[0076] Step: In a 10mL reaction flask, add compound I-1 (0.3mmol, 62.8mg), iodobenzene diacetate (0.6mmol, 193mg) and acetic acid (2mL) to react at 80°C, TLC (with thin layer chromatography Chromatography) was detected until the reaction was complete. Post-processing purification: the reaction mixture was washed with saturated sodium bicarbonate (20 mL×2), extracted with ethyl acetate (20 mL×2), the organic phases were combined, and washed with saturated NaCl (20 mL×1). After liquid separation, dry with anhydrous magnesium sulfate, remove the organic solvent under reduced pressure, separate and purify with silica gel column chromatography [V (petroleum ether): V (ethyl acetate) = 1-10: 1, the present embodiment preferably V ( Petroleum ether): V (ethyl acetate) = 3:1], the pure product was obtained as a white solid, the yield: 78%.

[0077] Compound II-1 was tested:

[0078] Melting p...

Embodiment 2

[0084]

[0085] In this example: R 1 is methyl; R 2 is 4-methyl; R 3 for hydrogen.

[0086] Step: In a 10mL reaction flask, add compound I-2 (0.3mmol, 67mg), iodobenzene diacetate (0.6mmol, 193mg) and acetic acid (2mL) to react at 80°C, TLC (with thin layer chromatography method) until the reaction was complete. Post-processing purification: the reaction mixture was washed with saturated sodium bicarbonate (20 mL×2), extracted with ethyl acetate (20 mL×2), the organic phases were combined, and washed with saturated NaCl (20 mL×1). After liquid separation, dry with anhydrous magnesium sulfate, remove the organic solvent under reduced pressure, separate and purify with silica gel column chromatography [V (petroleum ether): V (ethyl acetate) = 1-10: 1, the present embodiment preferably V ( Petroleum ether): V (ethyl acetate) = 3:1], the pure product was obtained, white solid, yield: 55%.

[0087] Compound II-2 was tested:

[0088] Melting point: 156-157°C

[0089] 1 H ...

Embodiment 3

[0094]

[0095] In this example: R 1 is methyl; R 2 For 4-benzyloxy; R 3 for hydrogen.

[0096] Step: In a 10mL reaction flask, add compound I-3 (0.3mmol, 94.6mg), iodobenzene diacetate (0.6mmol, 193mg) and acetic acid (2mL) to react at 80 ° C, TLC (with thin layer chromatography Chromatography) was detected until the reaction was complete. Post-processing purification: the reaction mixture was washed with saturated sodium bicarbonate (20 mL×2), extracted with ethyl acetate (20 mL×2), the organic phases were combined, and washed with saturated NaCl (20 mL×1). After liquid separation, dry with anhydrous magnesium sulfate, remove the organic solvent under reduced pressure, separate and purify with silica gel column chromatography [V (petroleum ether): V (ethyl acetate) = 1-10: 1, the present embodiment preferably V ( Petroleum ether): V (ethyl acetate) = 3:1], the pure product was obtained as a white solid, the yield: 62%.

[0097] Compound II-3 was tested:

[0098] Mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com