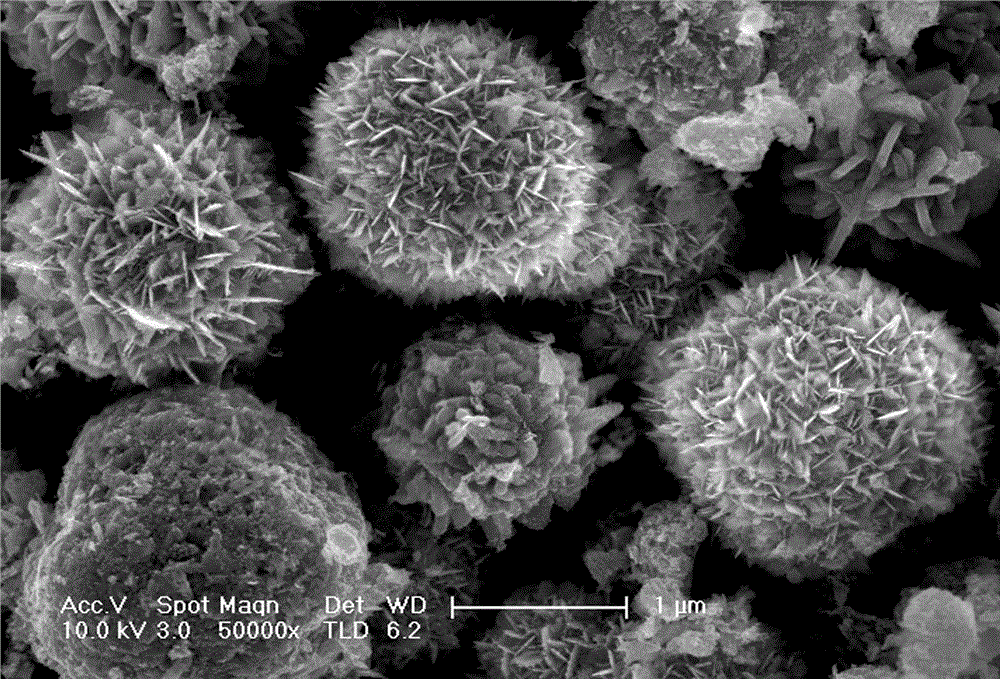

Preparation method for Ag doped ZnO nanometer gas sensitive material

A gas-sensing material and nanotechnology, applied in the field of gas-sensing sensors, can solve the problems of affecting material performance, increasing energy consumption, poor selectivity, etc., and achieve the effects of low preparation cost, stable performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Zinc nitrate and silver nitrate were dissolved in 80 mL of deionized water at a molar ratio of 100:2, and the cationic concentration was 0.1M to obtain solution A; according to the molar ratio of triethanolamine and urea of 100:4, the total molar mass of the two was 1 / 4 of the cationic concentration. 2 times weighed triethanolamine and urea dissolved in water, the volume ratio of water and complexing agent was 20:1, to obtain solution B; mixed solution A and solution B, stirred for 10min and then added to the polytetrafluoroethylene reactor, 80 The reaction was carried out at ℃ for 10 hours. After the reaction, the sample was centrifuged and precipitated. After repeated washing with deionized water and absolute ethanol for 2 to 3 times, the sample was dried at 60 ℃ for 10 hours to obtain Ag-doped ZnO nanomaterials.

[0018] The powder prepared in this embodiment is dispersedly coated on the gas sensor test element of the six-pin ceramic tube, and the response to aceton...

Embodiment 2

[0020] Dissolve zinc nitrate and silver nitrate in 80 mL of deionized water at a molar ratio of 100:1, and the cation concentration is 0.15M to obtain solution A; according to the molar ratio of ethylene glycol and urea of 100:2, the total molar mass of the two is the cation concentration Weigh 2 times of ethylene glycol and urea and dissolve in water, the volume ratio of water and complexing agent is 15:1, to obtain solution B; mix solution A and solution B, stir for 10min, then add to polytetrafluoroethylene reactor, The reaction was carried out at 70°C for 11 hours. After the reaction, the sample was centrifuged and precipitated. After repeated washing with deionized water and absolute ethanol for 2 to 3 times, the sample was dried at 60°C for 10 hours to obtain Ag-doped ZnO nanomaterials.

[0021] The powder prepared in this example is dispersedly coated on the gas sensor test element of the hexapod ceramic tube, and the WS-30A gas sensor test system is used to test the r...

Embodiment 3

[0023] Zinc acetate and silver nitrate were dissolved in 80 mL of deionized water at a molar ratio of 100:5, and the cation concentration was 0.2M to obtain solution A; The molar weight is 3 times of the cation concentration. Weigh ethylene glycol and hexamethylenetetramine and dissolve them in water. The volume ratio of water to complexing agent is 20:1 to obtain solution B; mix solution A and solution B and stir for 10 minutes After that, it was added into a polytetrafluoroethylene reactor and reacted at 100°C for 7 hours. After the reaction, the sample was centrifuged and precipitated, washed repeatedly with deionized water and absolute ethanol for 2 to 3 times, and dried at 60°C for 10 hours to obtain Ag-doped ZnO nanomaterials.

[0024] The powder obtained in this example is dispersedly coated on the gas sensor test element of the hexapod ceramic tube, and the WS-30A gas sensor test system is used to test the response to acetone gas at different concentrations, and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com