Method and device for speed control of power source

A speed control and power source technology, applied in the field of power source speed control, can solve problems such as reducing clutch service life and clutch wear, and achieve the effects of extending service life, reducing friction, and avoiding excessive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

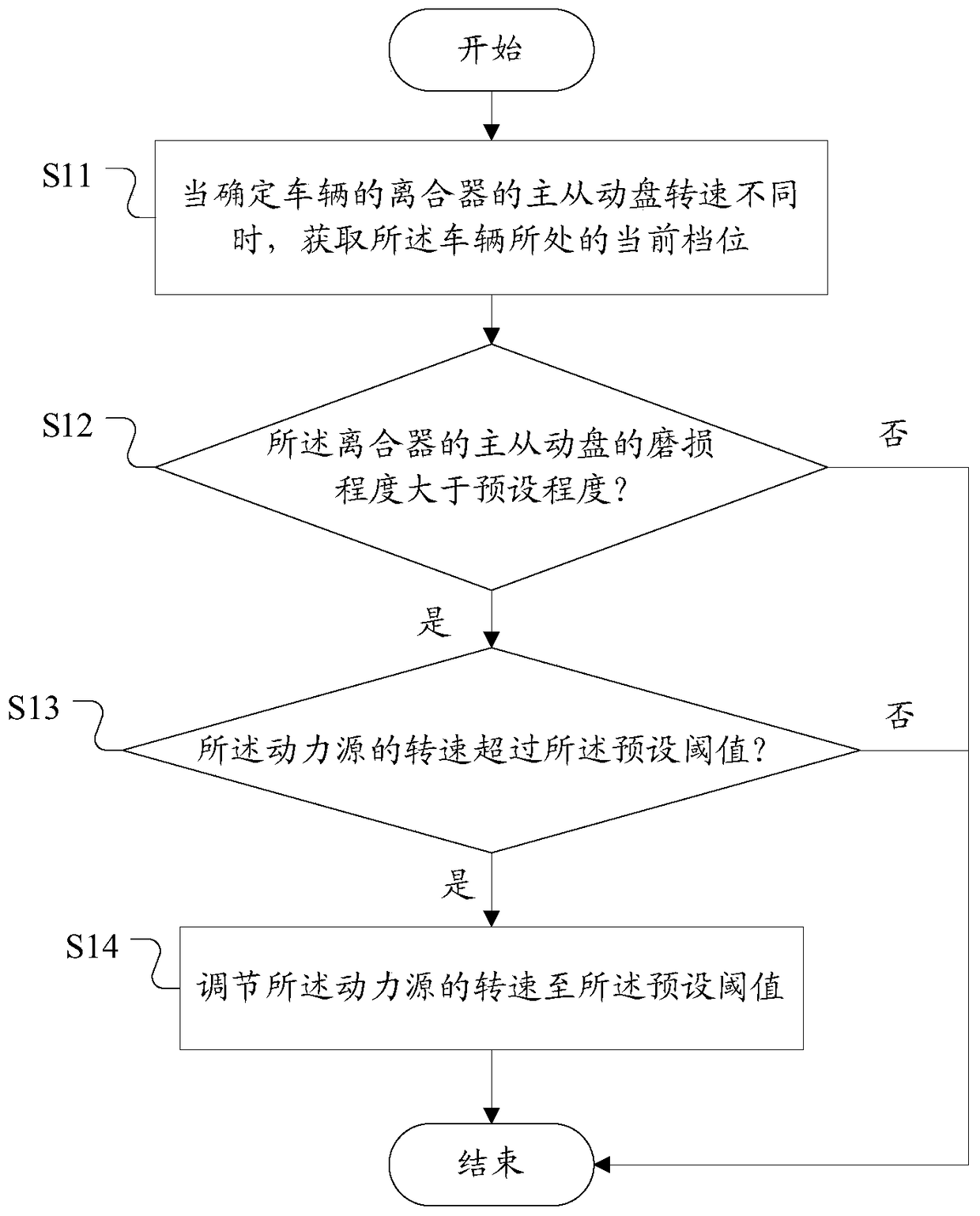

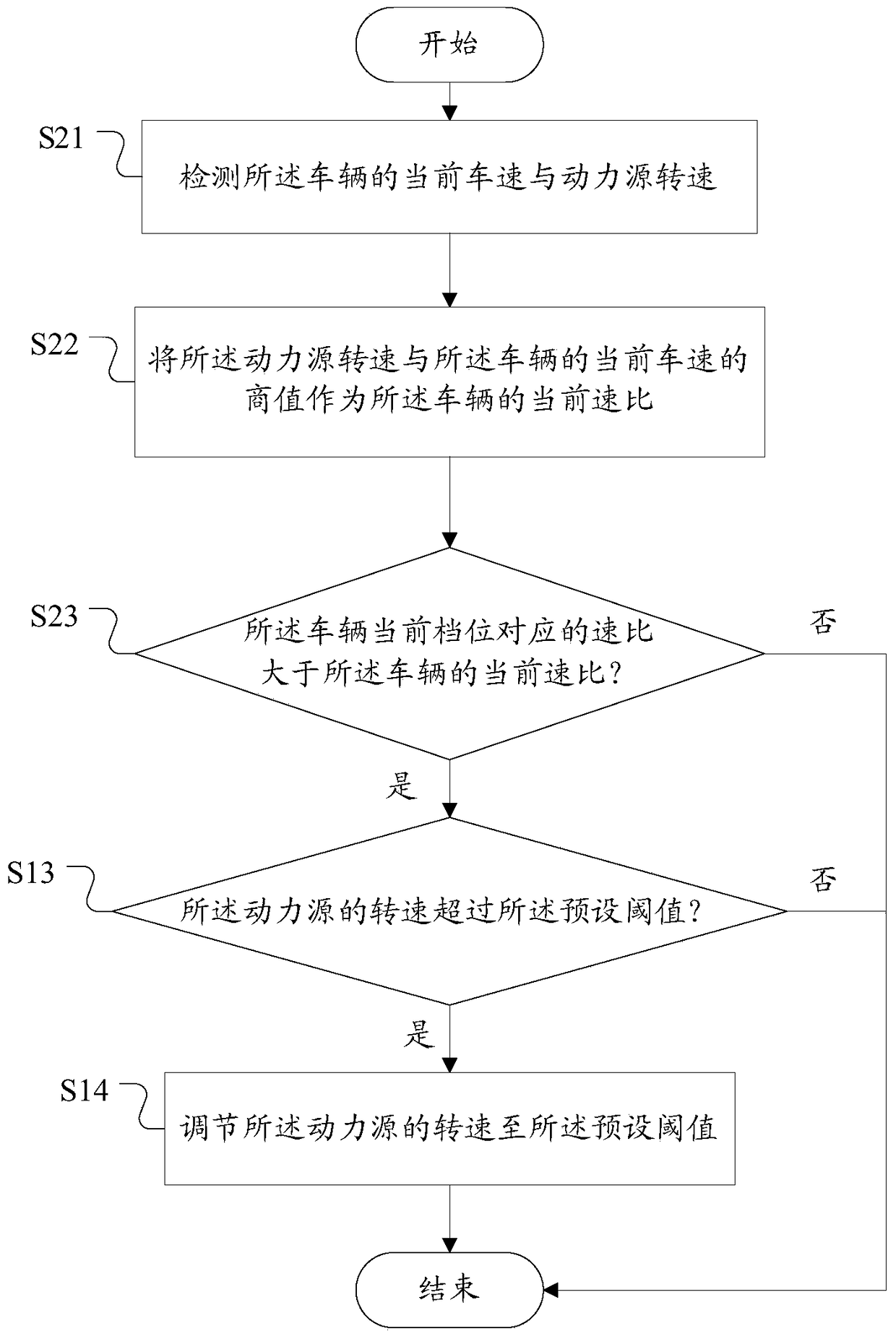

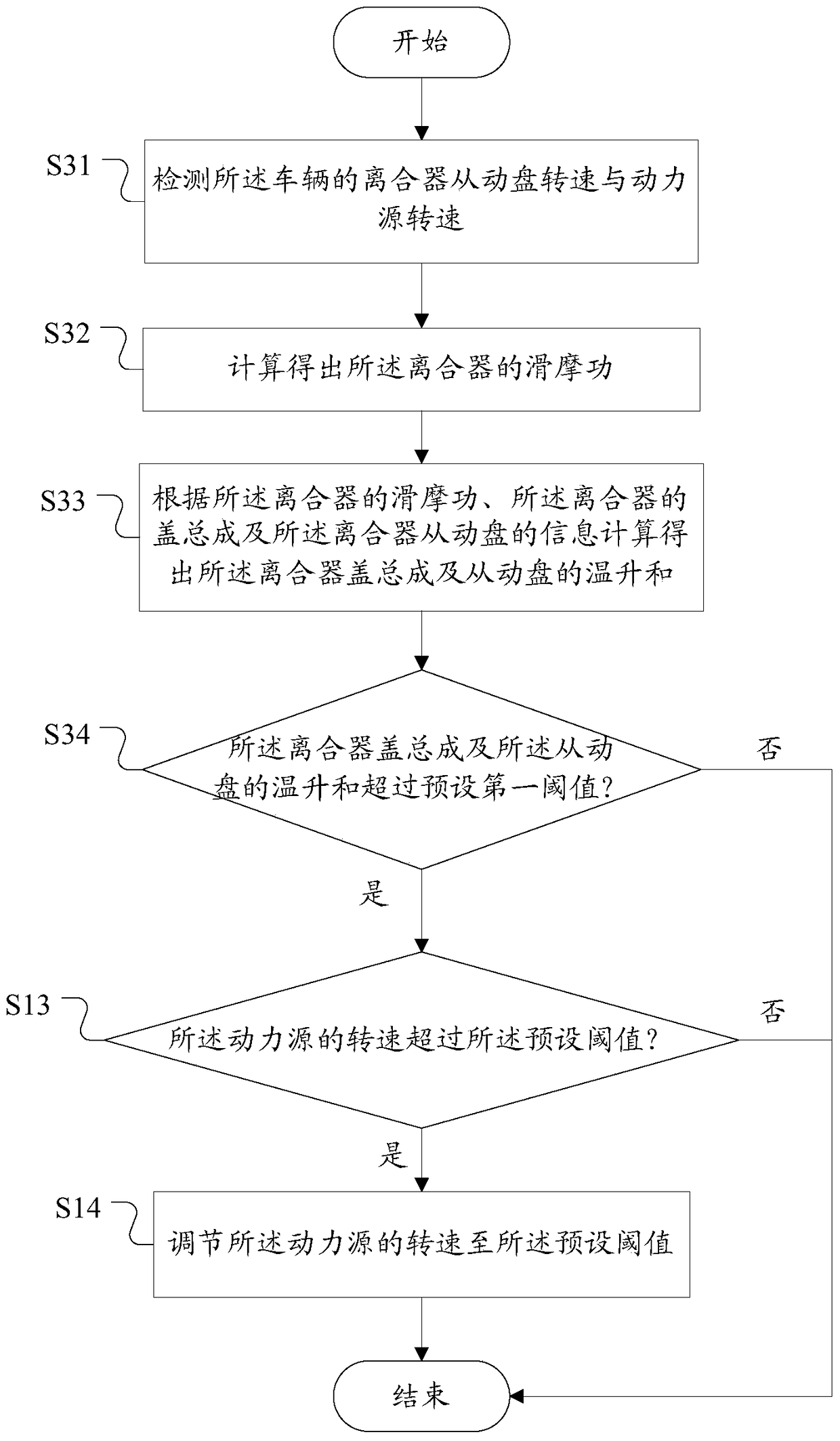

Method used

Image

Examples

Embodiment Construction

[0063] At present, at the starting stage, the vehicle needs to use the relative slip between the clutch master and the driven disc to increase the rotational speed of its transmission parts. But in this process, in order to make the vehicle start quickly, the engine speed is very high, and because the clutch is not in a fully engaged state, the driven plate of the clutch does not rotate synchronously with the driving plate, that is to say, the main, There is relative motion between the driven discs. And this kind of relative movement will lead to serious wear of the friction plate, and cause the temperature of clutch parts such as the pressure plate and flywheel to rise, and the excessive rise of the friction surface temperature will aggravate the wear of the friction plate, and affect the normal operation of the clutch, reducing the clutch wear. service life.

[0064] In order to explain the impact of the above conditions on the clutch, an example is given to illustrate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com