Formula and preparing method of polyurethane with high water absorption and foam structure

A polyurethane, high water absorption technology, applied in the field of polyurethane materials, can solve the problems of no cell structure, limited use areas, high density, etc., to achieve reduced density, excellent water absorption, good water absorption effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention is described further below:

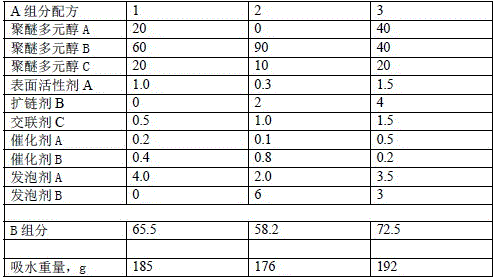

[0023] High water absorption provided by the present invention and the polyurethane with cell structure, the raw material that production adopts is as shown in the following table:

[0024] Formulation content and water absorption weight table

[0025]

[0026] 1) A component:

[0027] Polyether polyol A Propylene oxide-ethylene oxide copolyol or its combination, wherein the oxyethylene unit content is 15%, the average functionality is 3, and the average hydroxyl value is 56mgKOH / g

[0028] Polyether polyol B Propylene oxide-ethylene oxide copolyol or its combination, wherein the content of ethylene oxide units is 75%, the average functionality is 3, and the average hydroxyl value is 40mgKOH / g

[0029] Polyether polyol C is obtained by graft copolymerization of propylene oxide-ethylene oxide copolyol or its combination with acrylonitrile / styrene or a mixture of the two, wherein the conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com