A three-dimensional porous graphene ultra-thin film gas sensor and its preparation method

A gas sensor and porous graphene technology, applied in the field of sensors, can solve the problems of reduced contact area between graphene sheets and gas molecules, affecting the gas sensing performance of sensors, poor repeatability of sensors, etc., to achieve low-cost large-scale preparation, Achieve precise control and fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

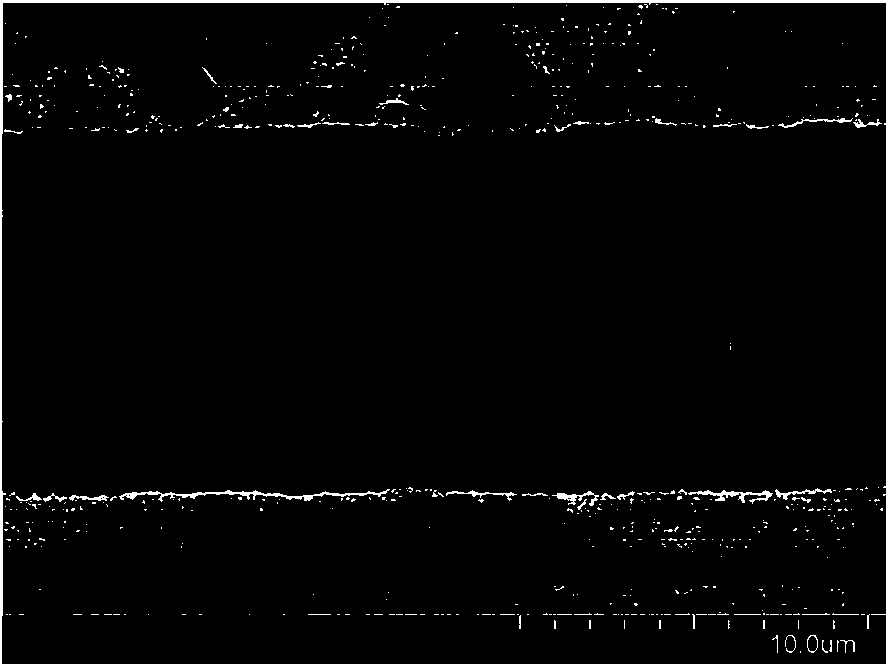

Image

Examples

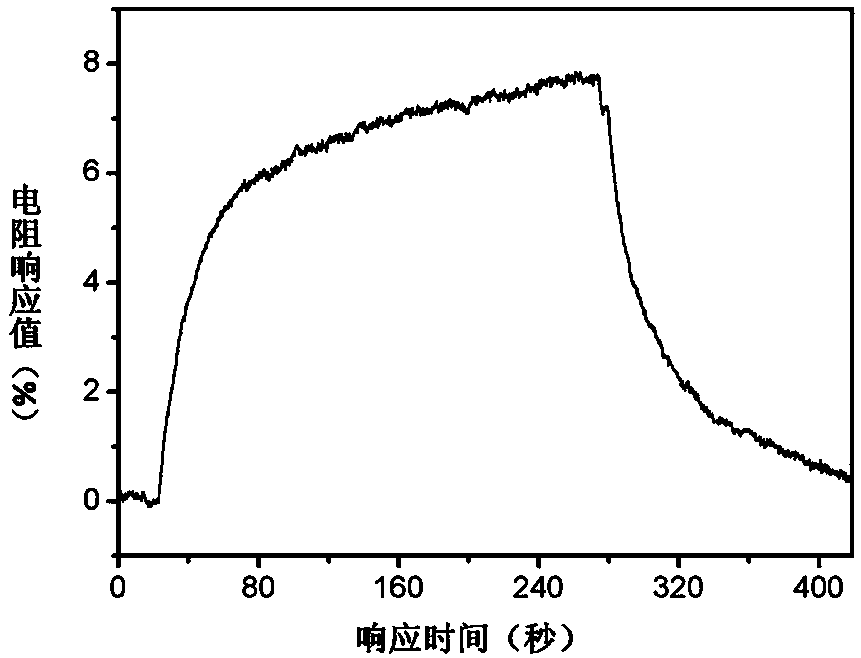

Embodiment 1

[0037] A preparation method of a three-dimensional porous graphene ultra-thin film gas sensor, comprising the following steps:

[0038] 1. After ultrasonic dispersion treatment of 1 mg / mL graphene oxide aqueous solution obtained by 200 mL Hummers method for 5 hours; add 80 mL of hydrogen peroxide solution with a concentration of 5 wt%, and then add 1 mL of ferrous sulfate solution with a concentration of 20 mM, 80 Hz ultrasonic dispersion for 30 min to form a graphene oxide dispersion, and then add hydrochloric acid to make the pH value reach 4;

[0039] 2. Place the above graphene oxide dispersion under a 2000 W UV lamp for reaction etching for 30 s, place it in a dialysis bag (molecular weight cut-off of 10,000) and dialyze for a week to obtain a negatively charged porous graphene dispersion, which is obtained by rotary evaporation The obtained negatively charged porous graphene dispersion was concentrated into 1mg / mL by instrument;

[0040] 3. Take 100 mL of negatively cha...

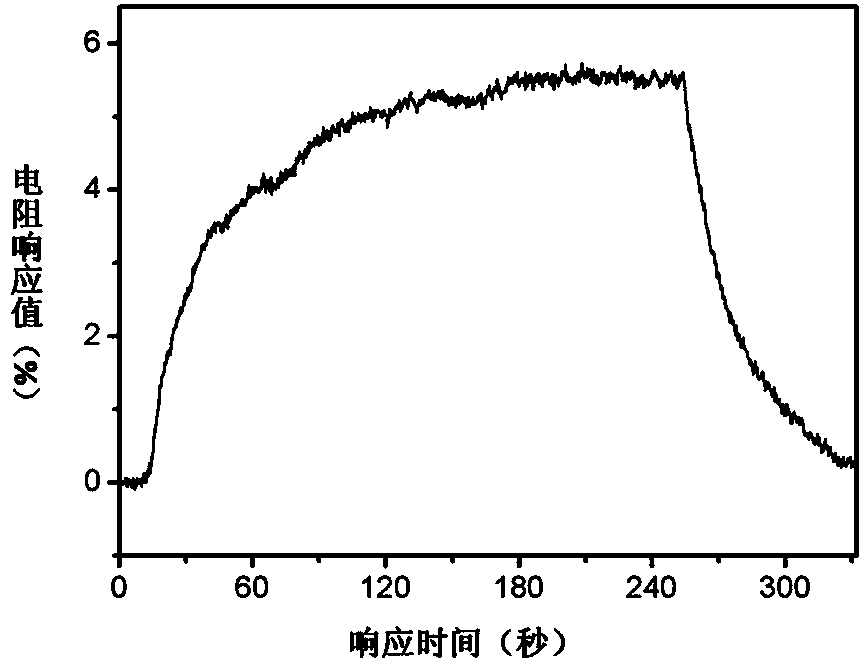

Embodiment 2

[0046] A preparation method of a three-dimensional porous graphene ultra-thin film gas sensor, comprising the following steps:

[0047] 1. After ultrasonic dispersion of 2 mg / mL graphene oxide aqueous solution obtained by 200 mL Hummers method for 5 hours, add 80 mL of hydrogen peroxide solution with a concentration of 5wt%, and then add 1 mL of ferrous sulfate solution with a concentration of 20 mM, and 80 Hz ultrasonic Disperse for 30 min to form a graphene oxide dispersion, then add hydrochloric acid to make the pH value reach 4;

[0048] 2. Place the above-mentioned graphene oxide dispersion under a 2000 W UV lamp for reaction etching for 30 s, then place it in a dialysis bag (molecular weight cut-off of 10,000) and dialyze it for a week to obtain a negatively charged porous graphene dispersion, which is obtained by rotary evaporation The obtained negatively charged porous graphene dispersion was concentrated into 1mg / mL by instrument;

[0049] 3. Add 1000 mg of p-phenyle...

Embodiment 3

[0053] A preparation method of a three-dimensional porous graphene ultra-thin film gas sensor, comprising the following steps:

[0054] 1. After ultrasonic dispersion of 1 mg / mL graphene oxide aqueous solution obtained by Hummers method in 200 mL for 5 hours, add 80 mL of hydrogen peroxide solution with a concentration of 5wt%, and then add 1 mL of ferrous sulfate solution with a concentration of 20 mM, and ultrasonicate at 80 Hz Disperse for 30 min to form a graphene oxide dispersion, then add hydrochloric acid to make the pH value reach 4;

[0055] 2. Place the above graphene oxide dispersion under a 3000 W UV lamp for reaction etching for 30 s, then place it in a dialysis bag (molecular weight cut-off of 10,000) and dialyze it for a week to obtain a negatively charged porous graphene dispersion, which is obtained by rotary evaporation The obtained negatively charged porous graphene dispersion was concentrated into 1mg / mL by instrument;

[0056] 3. Add 1000 mg of p-phenylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com