T-shaped flexible jointed limb wall with pre-embedded jointed beam section and its construction method

An even-leg wall and pre-embedded technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of unreliable connection relationship, complex structural stress, unstable structure, etc., and achieve simplification of site construction, reliable connection relationship, and convenience. construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

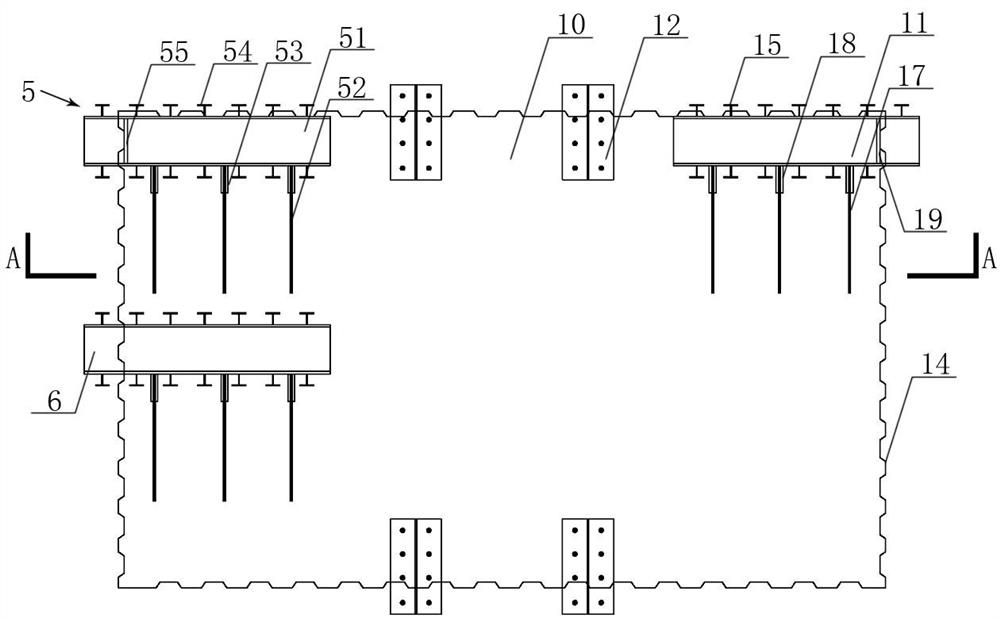

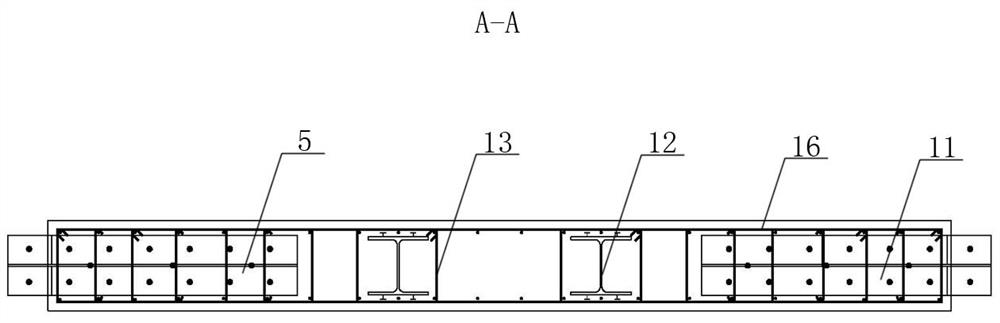

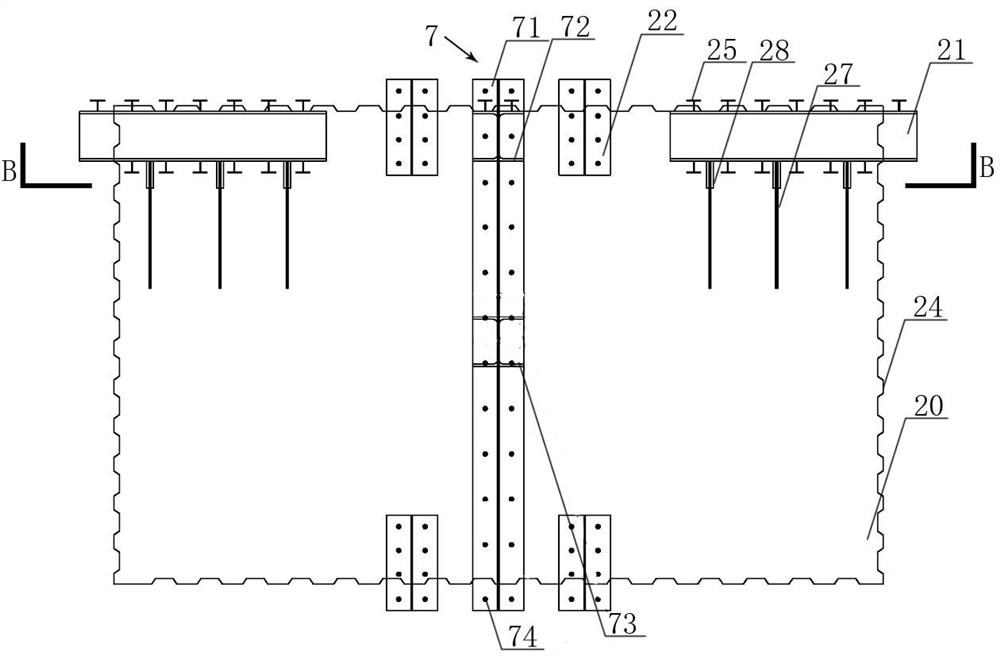

[0089] Example image 3 , Figure 4 As shown, this T-shaped flexible seam-like wall with a pre-buried seam beam section includes a first wall unit and a second wall unit that form a T-shaped first wall unit and a second wall unit, the first wall unit. Both the second wall units are prefabricated components, the concrete strength level is not less than C30, not higher than C60, the wall height is approximately layer high reduction floor thickness, the seams between the two are filled with filler 3, the filler The object 3 can select low-intensity filler, such as hollow small blocks, porous bricks, etc.

[0090] See figure 1 , figure 2 As shown, the first wall unit includes a first wall unit concrete wall and a first wall unit steel bone frame located inside the first wall unit concrete wall, and the central portion of the first wall unit concrete wall corresponds to the pre- The first wall unit is embedded, the upper or right side of the first wall unit concrete wall is embedded, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com