Preparation method of polyurethane resin for flexible packaging gravure table printing ink

A technology of polyurethane resin and flexible packaging, which is applied in ink, applications, household appliances, etc. It can solve the problems of glossiness, thermal stability, drying speed, water resistance, etc. that cannot meet the standards of solvent-based, environmental protection, and carcinogenicity. , to achieve stable and controllable production process, improve printing adaptability, and improve pigment dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

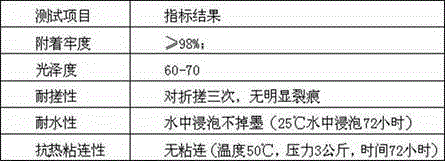

Examples

Embodiment 1

[0020] A kind of preparation method of the polyurethane resin that is used for flexible packaging gravure surface printing ink of the present invention comprises the following steps:

[0021] (1) Synthesis of polyester polyols, according to the hydroxyl: carboxyl molar ratio of n OH : n COOH =1.5: 1 ratio, the measured maleic acid and the measured methyl propylene glycol are dropped into the reaction vessel successively, heated up, start stirring after the material in the reaction vessel melts, add 150ppm catalyst, pass into nitrogen, When the temperature in the reaction vessel reaches 150°C, water begins to flow out. Control the temperature at the top of the fractionation tower to 100°C-102°C and continue heating. When the temperature in the reaction vessel reaches 220°C, the theoretical water volume is exhausted. When the temperature is below 70°C, take a sample to measure the acid value. When the acid value is 25mgKOH / g, start vacuuming. First, slowly vacuumize under the c...

Embodiment 2

[0027] A kind of preparation method of the polyurethane resin that is used for flexible packaging gravure surface printing ink of the present invention comprises the following steps:

[0028] (1) Synthesis of polyester polyols, according to the hydroxyl: carboxyl molar ratio of n OH : n COOH =1.8:1 ratio, the measured maleic acid and the measured methylpropanediol are dropped into the reaction vessel successively, heated up, start stirring after the material in the reaction vessel melts, add 120ppm catalyst, pass into nitrogen, When the temperature in the reaction vessel reaches 150°C, water begins to flow out. Control the temperature at the top of the fractionation tower to 100°C-102°C and continue heating. When the temperature in the reaction vessel reaches 220°C, the theoretical water volume is exhausted. When the temperature is below 70°C, take a sample to measure the acid value. When the acid value is 20mgKOH / g, start vacuuming, first slowly vacuumize under the condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com