Preparation method of dried pork

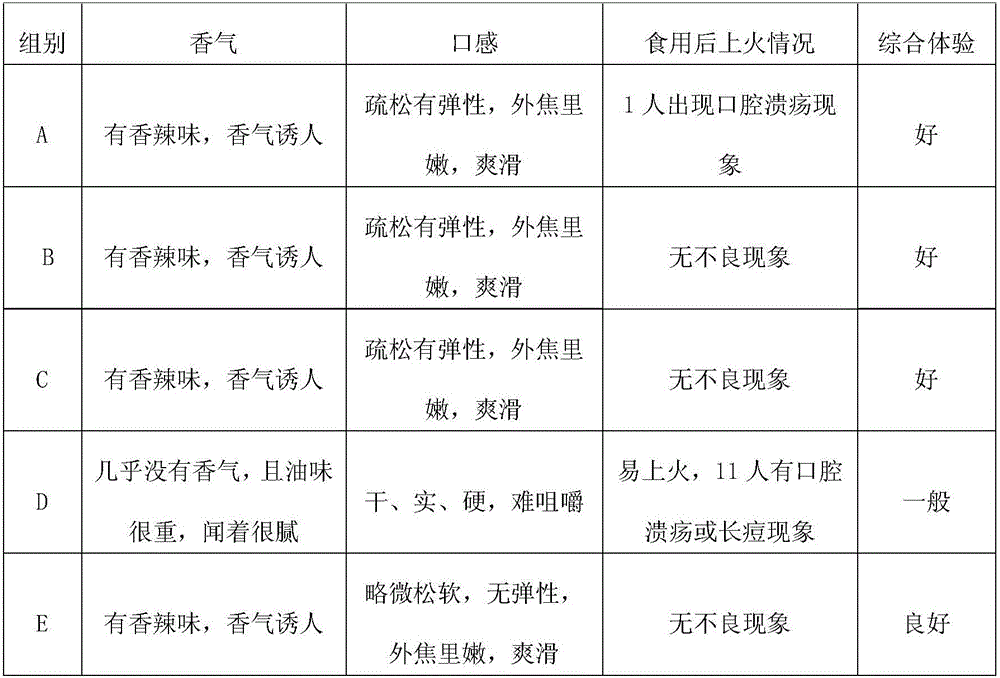

A technology of pork jerky and minced meat, which is applied in the field of jerky processing, can solve the problems of restricting the development of jerky pork, getting angry, unhealthy and other problems, and achieve the effect of good marinating effect, charred outside and tender inside, and attractive aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of present embodiment pork jerky, comprises the following steps:

[0033] (1) Material selection: select the pork legs of strong pigs, remove the bones and fat, select the lean meat, wash the lean meat, cut into pieces, put it into a meat grinder and grind it, and get the minced meat for later use;

[0034] (2) Pickling: Mix the spare minced meat obtained in step (1) with the marinade according to the mass ratio of 40:1, seal it with plastic wrap and let it stand for 20 minutes, and then put it in a vacuum environment at 50°C Leave it for 20 minutes, and finally, let it stand for 100 minutes in a vacuum environment at -3°C. After the marinating is completed, the marinated minced meat obtained is ready for use;

[0035] Among them, the marinade consists of 5 parts by weight of peanut oil, 1 part of fennel, 5 parts of chili sauce, 2.5 parts of cinnamon, 0.1 part of Yizhi kernel, 0.5 part of star anise, 0.2 part of salt, 0.05 part of polyethylene gly...

Embodiment 2

[0041] The preparation method of present embodiment pork jerky, comprises the following steps:

[0042] (1) Material selection: select the pork legs of strong pigs, remove the bones and fat, select the lean meat, wash the lean meat, cut into pieces, put it into a meat grinder and grind it, and get the minced meat for later use;

[0043](2) Pickling: Mix the spare minced meat obtained in step (1) with the marinade according to the mass ratio of 70:1, seal it with plastic wrap and let it stand for 10 minutes, and then put it in a vacuum environment at 35°C Leave it for 40 minutes, and finally, let it stand for 150 minutes in a vacuum environment at 0°C. After the marinating is completed, the marinated minced meat obtained is ready for use;

[0044] Among them, the marinade consists of 4 parts by weight of peanut oil, 2.5 parts of fennel, 3 parts of chili sauce, 1 part of cinnamon, 1 part of Yizhi kernel, 0.1 part of star anise, 0.5 part of salt, 0.01 part of polyethylene glycol,...

Embodiment 3

[0050] The preparation method of present embodiment pork jerky, comprises the following steps:

[0051] (1) Material selection: select the pork legs of strong pigs, remove the bones and fat, select the lean meat, wash the lean meat, cut into pieces, put it into a meat grinder and grind it, and get the minced meat for later use;

[0052] (2) Pickling: mix the spare minced meat obtained in step (1) with the marinade according to the mass ratio of 55:1, seal it with plastic wrap and let it stand for 15 minutes, and then put it in a vacuum environment at 43°C Leave it for 30 minutes, and finally, let it stand for 125 minutes in a vacuum environment at -2°C. After the marinating is completed, the marinated minced meat obtained is ready for use;

[0053] Among them, the marinade consists of 4 parts by weight of peanut oil, 1.7 parts of fennel, 4 parts of chili sauce, 1.5 parts of cinnamon, 0.5 parts of Yizhi kernels, 0.2 parts of star anise, 0.3 parts of salt, 0.03 parts of polyethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com