Maintenance decision-making method for diesel engine fuel oil system through cost analysis in combination with Bayesian network model

A technology of Bayesian network and fuel system, which is applied in the field of diesel engine fuel system maintenance decision-making based on cost analysis combined with Bayesian network model. problem, to achieve the effect of ensuring operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0045] to combine Figure 1-2 , the present invention comprises the following steps:

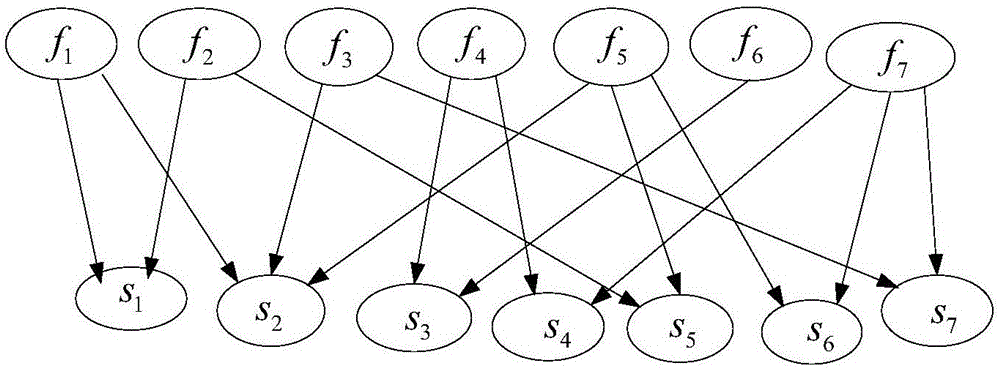

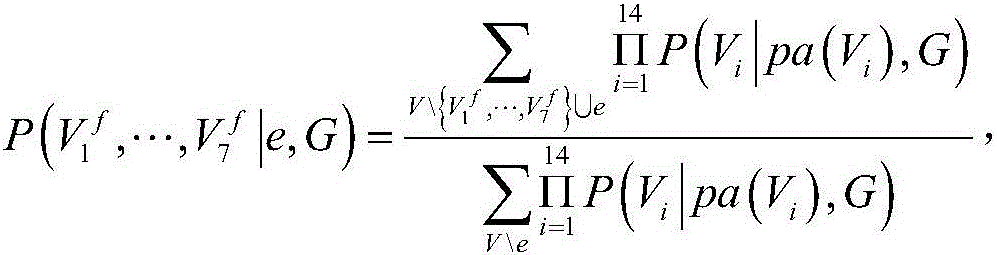

[0046] 1. Establish a Bayesian network model of the fuel system. In the Bayesian network model, the external symptom s i Including: aftermath fluctuation frequency increase s 1 , the amplitude of the aftermath oscillation decreases by s 2 , the injection duration increases s 3 , the crest factor increases s 4 , the kurtosis decreases s 5 , the needle valve opening pressure decreases s 6 , the maximum injection pressure decreases s 7 ;fault type f j Including: the oil return hole is too large f 1 , Plunger couple wear f 2 , Outlet valve failure f 3 , oil injection hole clogged f 4 , the card on the needle valve f 5 , Injector drip f 6 , Leakage of high-pressure oil pipe f 6 ;

[0047] 2. Collect the pressure signal of the high-pressure oil pipe of the diesel engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com